Glucose Equipments

MVR Evaporator for waste water,sewage,chemicals treatment

As early as in 1960s,Germany and France have applied this technology successfully to chemical,pharmaceutical,paper-making,wastewater treatment and desalination fields.

The MVR circulation evaporator is suitable for evaporation of products insensitive to high temperatures when high evaporation is required.

MVR Evaporator for whey processing,fishmeal,fish oil,fish meal processing

No supplement of additional fresh steam is required when the system reach a stable state.

MVR Forced circulation evaporator

Theoretically using MVR evaporators save more than 80% of energy than conventional evaporator, save more than 90% water, reduce more than 50% of floor space.

Industrial Use Mechanical Vapor Recompression MVR Evaporator

which is evaporated from the liquid material to rise its temperature and pressure, so as to reuse it as heating source to evaporate the liquid material again.

The MVR circulation evaporator is suitable for evaporation of products insensitive to high temperatures when high evaporation is required.

automatic MVR evaporator for coffee processing line

the principle is to use the secondary steam which is produced through compressing the steam by the steam compressor , secondary steam heat and temperature is increased by the compressor, steam compressed into the evaporator as the heat source, again makes

Mechanical Vapor Recompression MVR falling film evaporator for sodium chloride

evaporator uses two steam generated in the evaporator, the compressor, pressure, temperature, enthalpy increase, and then sent to the heating chamber of the evaporator as heating steam, feed liquid to maintain the boiling state, and heating steam is conde

Triple-effect Stainless Steel MVR wine evaporator for sale

Ltd has the aptitude to design and manufacture A-class boiler and A1, A2,A3 type of pressure vessel.

MVR evaporator for ammonium sulfate

The most common use of this evaporator is as an evaporative crystallizer with materials having relatively flat or inverted solubility.

Top Quality efficient chemical mvr evaporator

Top Quality efficient chemical mvr evaporatorProduct Description Product Application Company Introduction Our Certificate Our Customers Packaging Process Contact Us FAQAbout Delivery timeA-----Usually we send tne shipment

PJZ type Thermal Vapor Recompression evaporator (TVR)

PJZ type Thermal Vapor Recompression evaporator (TVR)Product introduction:Thermal Vapor Recompression device (TVR), according to the heat pump principle, evaporation from the evaporator is compressed to the high pressure o

General industrial equipment tvr rising film evaporator for chemical industry

Working pinciples: Compress secondary steam by using steam centrifugal compress or other steam com pression device to make sure its physical properties meet with the requirements for heating steam; evaporation that uses it as heating steam only requires f

Ferric Chloride TVR thin film evaporator evaporator

Our company is the largest manufacturer of alcohol, fuel ethanol and DDGS high protein feed complete equipment in China.

China supplier 380V industrial tvr evaporator for food processing

With equivalent or higher performance than the first effect, the thermal pump saves vapour consumption and therefore decreases investment in the equipment.

Ferric Chloride TVR desalinization rotary evaporator

Our company is the largest manufacturer of alcohol, fuel ethanol and DDGS high protein feed complete equipment in China.

effect film-falling evaporator concentrates the solution by means of vaporizing the thin solution through film-falling principle.

ISO Full Automatic TVR Multi-effect Falling Film Plate Evaporator/Concentrator/Concentrating Machine

The evaporation mode of plate falling film is multi-effect evaporation.

Ferric Chloride automatic TVR VAPOR COMPRESSOR EVAPORATOR for effluent

Our company is the largest manufacturer of alcohol, fuel ethanol and DDGS high protein feed complete equipment in China.

Our company has experience in exporting heat exchange equipment and evaporating equipment to global.

Ferric Chloride TVR evaporator for brine desalting

Our company is the largest manufacturer of alcohol, fuel ethanol and DDGS high protein feed complete equipment in China.

Our company has experience in exporting heat exchange equipment and evaporating equipment to global.

GOJE ODM & OEM multi-effect plate evaporator for heating or cooling

Our company has experience in exporting heat exchange equipment and evaporating equipment to global.

Ferric Chloride TVR evaporator equipment

Our company is the largest manufacturer of alcohol, fuel ethanol and DDGS high protein feed complete equipment in China.

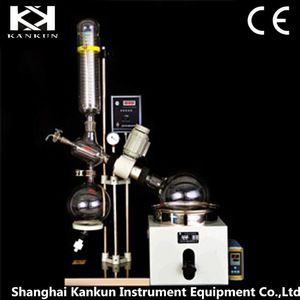

50L Rotary triple effect evaporator with water bath

Rotary evaporator is under normal/negative pressure, with constant heating, use the different boiling point of the liquid material to get your target solvent.

Well-designed thin film citric acid multi effect vacuum evaporator

Well-designed thin film citric acid multi effect vacuum evaporatorProduct Description Applications:1.Milk/Dairy industry (milk, yoghurt, serum, etc.).2.Beverages (juices, fruit concentrates, tea).3.Wine industry (self-enrichment of grape

20017 Hot sale Double effect Falling film Evaporator / food / Chemical /

Falling film evaporator widely used in fresh milk,tomato juice,soybean milk,xylitik,sirbitol,VC, honey,starch sugar,fructose,glucose,drink etc heat sensitive material concentration.

food processing glass rotary juice concentrate evaporator

2000A industrial rotary evaporator is a newly designed new generation smart industrial rotary evaporator, digital display of temperature, control part use high-performance single chip as main control chip, adopt special control program according to contro

Double effect falling film evaporator and Ethanol recovery

5 meters/seconds, heat transfer efficiency and production capacity is larger, when heated to overheat under higher than normal liquid boiling point, steam and liquid mixture enter into the evaporation chamber, then separate, steam discharge from the upper

Lab Used Wiped Film Evaporator for Molecular Distillation

liquid film formed when material liquid flows through the tube wall.

Liquid Vacuum Evaporator Honey Evaporator

The working principle is to evaporate the excess water in liquid, such as honey, propolis and traditional Chinese medicine in vacuum, and recover it through condenser, so as to achieve the purpose of purification.

Falling Film Vaccum Evaporator for Ammonium Chloride Treatment in Dyeing Industry

Triple Effect falling film evaporator can be used during the production of food, sugars, and pharmaceuticals, the chemical waste water, and the bio-engineering process for the purpose of concentrating and recovering of low viscosity materials.

Evaporator for milk processing/Multi effect evaporator

Multi effect evaporator is widely used in food, food deep processing, beverage, environmental conservation, chemical and other industry.

Mechanical Vapor Recompression MVR Blower Pump Steam Compressor HDSR-WNS 200

s a roots type blower pump, rotary lobe.

Multi effect evaporator for pharmaceutical industry

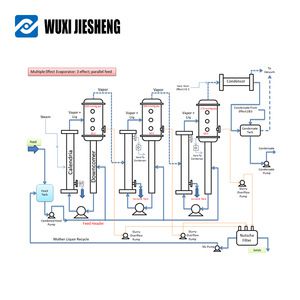

The multiple-effect configuration combines two or more evaporator bodies to conserve steam, which is condensed in the first-effect heat exchanger only.

Zero Discharge Waste water Treatment Plant Multi effect Thin Film Evaporator

Multi effect Waste water Evaporator is flexible for various kinds of wastewater, including Inorganic Wastewater and organic wastewater, such as Sodium chloride wastewater, Phenylalanine wastewater, sodium sulfate wastewater, ammonium chloride wastewater,

Automatic flash evaporation and smell remove System

Automatic flash evaporation and smell remove System,is operated by SIEMENS PLC.

Vacuum falling film industrial multi effect evaporator price

composed of several domestic Propellent enterprises, has always been insisting this business philosophy: opening-up and cooperation, mutual improvement with the cooperative partner and growing together with employees.

Plate concentrator equipment used for food chemical industry

Failure automatically shut down the steam, feed flow automatic adjustment, concentration of field display and automatic control and other functions.

Professional PET crystallizer for flakes from manufacturer

CSG series is a fully automatic drying system with zeolite desiccant beds, which Can be used with Hopper Bank Series and multi-hopper systems.

Wholesale cheapest high quality 3850*1440*2370mm 27.3 kw PET crystallizers

GCR closed-loop crystallizers are used for constant crystallization of un-crystallized PET regrinds or pellets.

MAP Plant Production Cooling Crystallizer DTB Crystallizer/ OSLO Crystallizer

Production Cooling Crystallizer DTB Crystallizer/ OSLO Crystallizer OSLO Cryatllizer Company Information Port of loading: Shanghai port /Ningbo Port Our Services Packag

SMD active crystal SG-310SN 21M 21MHZ 21.000MHZ 3.2*2.5mm

We can ship out within 1-3days after you confirmed the payment.

Continuous High-efficiency Negative Preussure DTB Draft Tube Baffle Crystallizer

DTB type crystallizer, is a turbulent flow crystallizer complete with a draft tube and baffle.

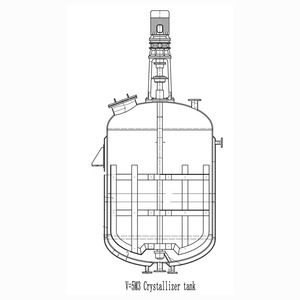

Stainless steel food industrial crystallizing tank/cooling crystallizer with good price

The crystallizing tank mixture after the reaction, the sandwich domestic demand chilled water or chilled water rapid cooling crystallization apparatus, the key lies in the mezzanine area the size of agitator structure and material in the form of exports,