Products:

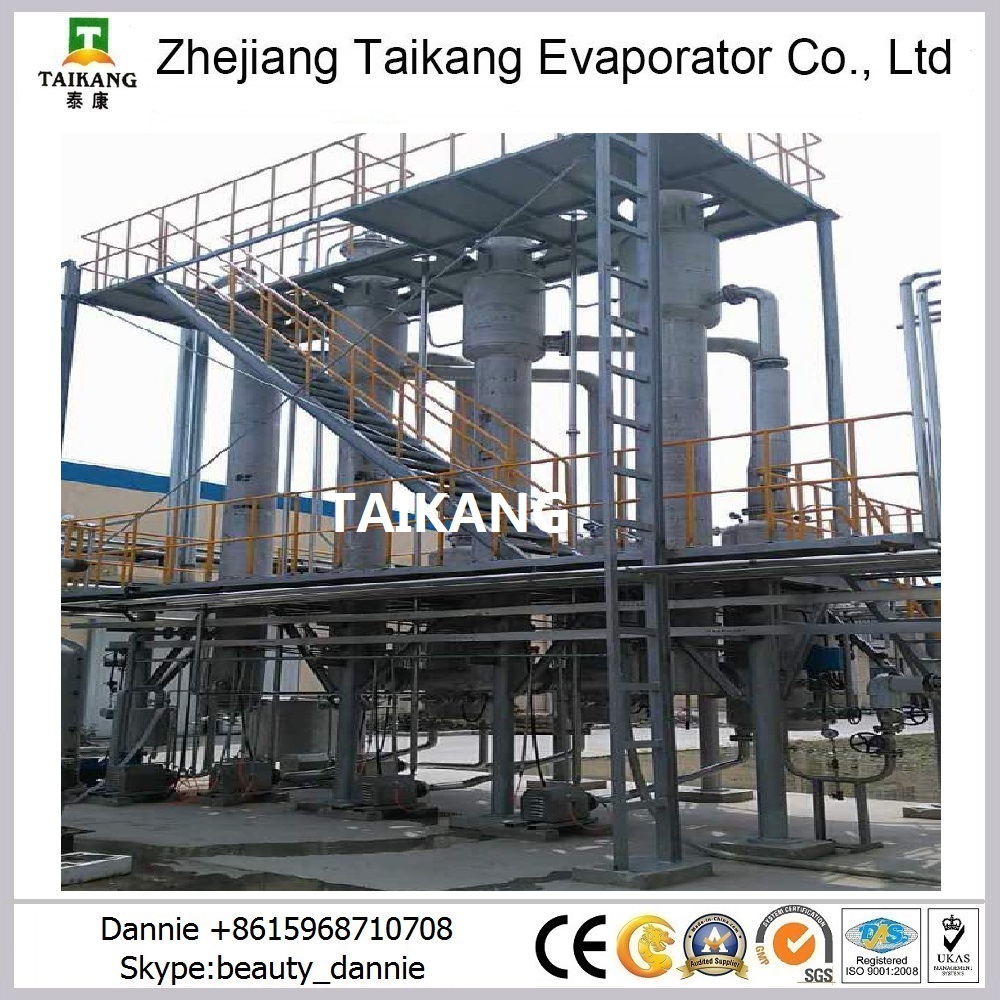

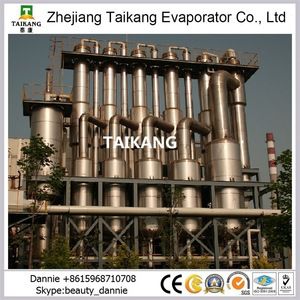

Triple Effect Falling Film Evaporator RNJM03-(0.3T/h--100T/h) Evaporation Capacity

Scope of Application:

Triple Effect falling film evaporator can be used during the production of food, sugars, and pharmaceuticals, the chemical waste water, and the bio-engineering process for the purpose of concentrating and recovering of low viscosity materials. Process steam for such evaporators include advection, downstream, upstream and cross-flow. The low-temperature concentration process is particularly designed based upon the properties and concentrations of different materials.

Features:

The continuous concentration and falling-film evaporator is manufactured by introducing the most advanced evaporator technology abroad and can be completes with different processes. Featuring high heat transfer coefficient, great evaporation capacity, minimized power consumption, low motor power, small space occupation, simple construction and automated cleaning. This unit is different with traditional evaporators in China with respect to their structure and process flow, and it is one of the most power-efficient and most advanced evaporation apparatuses in China.

Control Mode:

DCS or PLC automatic control, semi-automatic control or manual control (one operation).

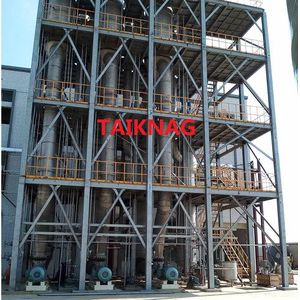

Evaporation plant composition and major components

This unit comprises mainly the heating chamber, separation chamber, condenser, vacuum pump, circulation pump, defoaming device, cleaning system, electric cabinet, platform, and all piping, gauges and valves.

Usage:

Triple-effect falling film evaporators mainly adapts in continuous evaporation and concentration under low temperature,Can process milk,glucose,starch,xylose,pharmaceutical,biological engineering,environmental protection,waste liquid recycling etc; Especially suitable for processing the material with character of heat sensitive,viscosity and foamability. The machine has characteristics of high heat transfer efficiency,material heating In short time etc.

Components:

| 1 | First/Second/Third Effect Heaters |

| 2 | First/Second/Third Effect Seperators |

| 3 | Condensor |

| 4 | Feed Inlet/discharge Pump, Condensate Water Pump, Vacuum Pump |

| 5 | 1st/2nd/3rd Effect Circulation Pump |

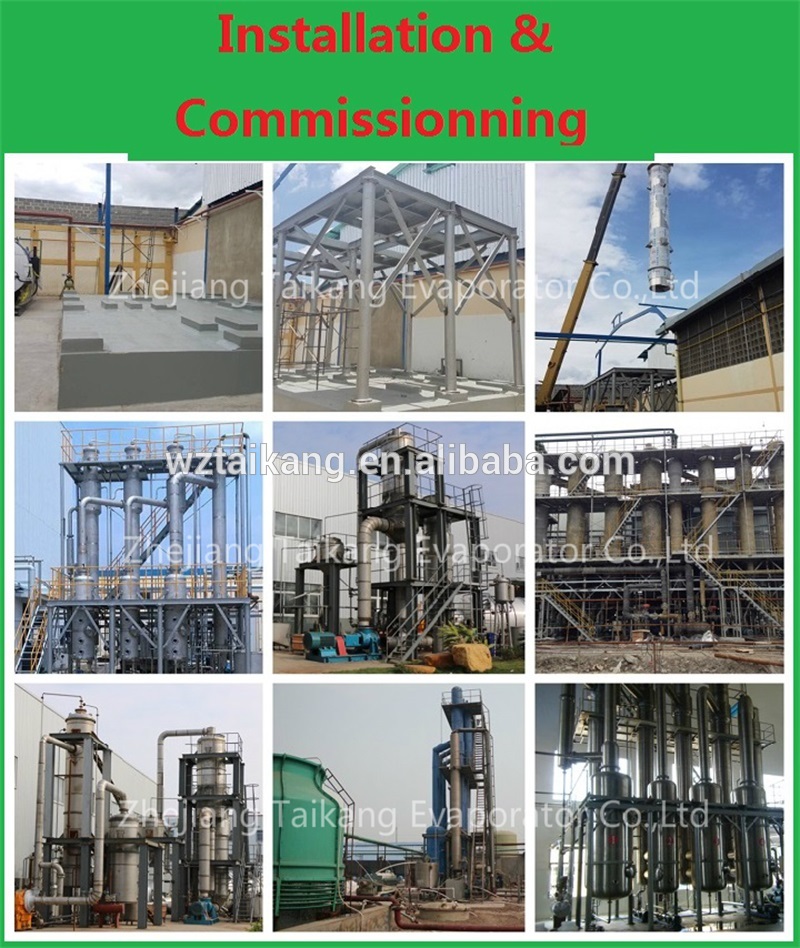

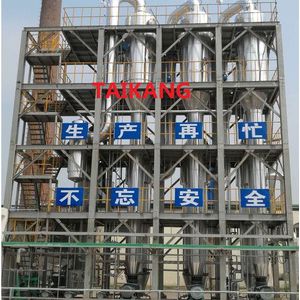

| 6 | Stairs, Fences, Platforms, Steel Structures |

| 7 | Feed Circulation Pipes, Steam Pipes, Condensate Water Pipes and other pipes |

| 8 | Operation Platforms |

| 9 | Fully Automatic Control System |

| 10 | Valves, elbows, pipelines and other accessaories. |

Characteristics:

1. High heat transfer efficiency and material heating In short time realized for the heating system even heated with steam and feed liquid evaporated in flow film style,The equipment has smaller energy consumption,Steam consumption and cool water circulation amount if equipped with heat pressure pump.

2. Feed liquid evaporated while accelerated flow downward along the pipe wall that suitable for evaporation and concentration of high viscosity material.

3. Liquid heated in very short time for it inner film evaporated in every tube which is highly suitable for food concentration,can maximum preserve food nutritious.

4. Whole process operated under vacuum condition Which meet the sanitary requirement and environmental protection requirement,Meanwhile can significantly reduce the evaporation temperature.If equipped with heat pressure pump,part of secondary steam will be re-inhaled and mixed with live steam.Steam pass through pump, spray into heating shell,spread rapidly and make liquid heated gently,is very suitable for concentration of heat sensitive products.

5. Equipment suitable for evaporation and concentration of foamability material, Liquid film evaporated in heating tube then formed liquid-vapor separate,meanwhile the most part of feed extracted from the bottom of cylinder,Only small part of feed liquid and all secondary steam enter into separator,therefore Feed liquid foam formed can be completely avoided in the whole process.

6. Equipment can also sterilize food Feed liquid flow to sterilizer after preheated,Temperature up to 94℃and lasting for 24 seconds,Then flow into first stage,Liquid evaporated in seconds then temperature drop at once.

7. Equipping with CIP cleaning system,clean in spot,operated conveniently without dead angle.

8. Continuous feed material and discharge material.

9. Can equip with automatic system,automatic control feed material capacity,heat temperature and discharge viscosity and cleaning.Can equip with protection facilities in case of suddenly blackout,break down which will cause trouble with heat sensitive products,other safeties,alarm facilities can achieve automatic operate and control.

China

China