We promise 12 months warranty and return cargos if quality problem

China XianChen tapioca starch food grade farina screening sieve machine

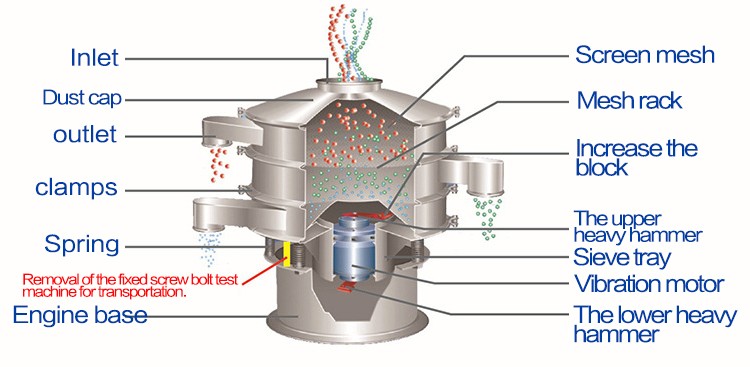

Product Description---tapioca flour sieving machine

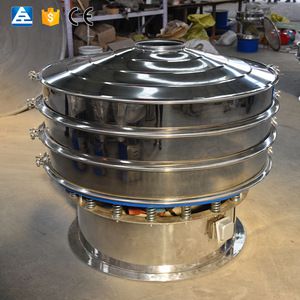

Actual photos ---tapioca flour sieving machine

There are two cleaning devices, bounce ball structure and ultrasonic system.

a.This cleaning device is suitable for screening general raw materal.

b.Generally,the raw materal size is more than 0.1mm(100 microns) granular,power,liquid.

c.The raw materal should have no viscidity.

d.This cleaning device have a much lower coat than ultrasonic system.

Ultrasonic system cleaning device

b.Generally, the micron power is more than 0.1mm (100 micron).

c.This cleaning device have a much higher coat than bounce ball cleaning device.

Features ---tapioca flour sieving machine

1. High efficiency, refined design, duration, any powders and mucilage are suitable for using.

2. Easily replace traditional screen, simple operation, easy clean.

3. No jam screen, no powder flight, filter size between the factors of the grid, powder 500 mm.

4. Discharge the impurity and coarse materials automobile and operates continuously.

5. Unique screen flame design, long duration, only 3-5 to replace screen.Small volume, move easily.

6. The highest layers of the screen are about 5 layers. But 3 layers are suggested.

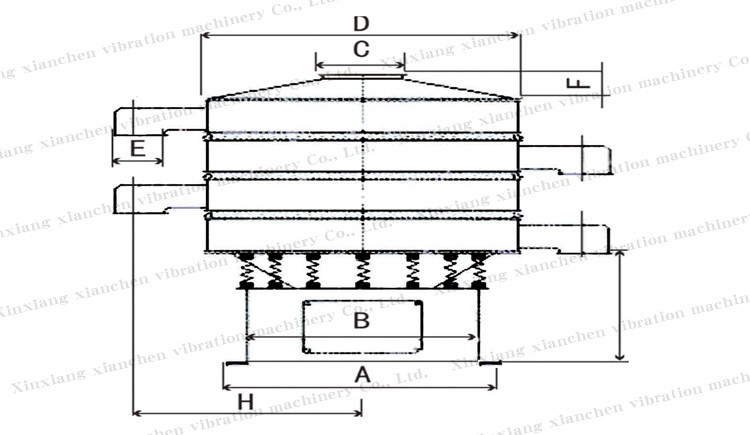

Dimensions---tapioca flour sieving machine

Model | A | B | C | D | E | F | H | I | Single layer height | Double height | Three layer height |

XC-600 | 560 | 460 | 120 | 600 | 130 | 95 | 450 | 410 | 750 | 860 | 1060 |

XC-800 | 680 | 580 | 200 | 800 | 150 | 100 | 550 | 460 | 840 | 980 | 1120 |

XC-1000 | 800 | 700 | 200 | 970 | 150 | 120 | 680 | 460 | 840 | 980 | 1120 |

XC-1200 | 980 | 860 | 250 | 1170 | 180 | 140 | 790 | 580 | 1010 | 1150 | 1290 |

XC-1500 | 1180 | 1060 | 280 | 1470 | 200 | 170 | 930 | 580 | 1060 | 1220 | 1380 |

XC-1800 | 1490 | 1350 | 320 | 1770 | 200 | 180 | 1090 | 580 | 1220 | 1390 | 1560 |

Pecifi-----tapioca flour sieving machine

Model | Power(KW) | Screen dish(φ) | effective area

| Layer |

XC-600-1S XC-600-2S XC-600-3S | 0.25 0.55 0.55 | 560 | 0.2375 | 1 2 3 |

XC-800-1S XC-800-2S XC-800-3S | 0.55 0.75 0.75 | 760 | 0.4416 | 1 2 3 |

XC-1000-1S XC-1000-2S XC-1000-3S | 0.75 1.1 1.5 | 930 | 0.6789 | 1 2 3 |

XC-1200-1S XC-1200-2S XC-1200-3S | 1.1 1.5 1.75 | 1130 | 1.0382 | 1 2 3 |

XC-1500-1S XC-1500-2S XC-1500-3S | 1.5 2.2 2.2 | 1430 | 1.6052 | 1 2 3 |

XC-1800-1S XC-1800-2S XC-1800-3S | 2.2 2.2 3.0 | 1730 | 2.3523 | 1 2 3 |

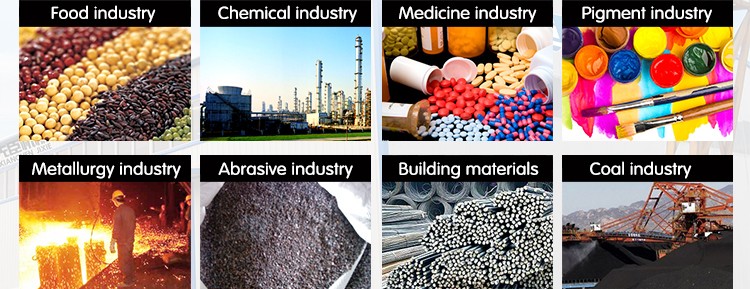

Application---tapioca flour sieving machine

- Chemical industry: resin, coatings, industrial medicine,cosmetics, paint, Chinese medicine powder and so on.

- The food industry: sugar, starch, salt, Rice noodles, milk powder, Soybean Milk, egg powder, soy sauce, juice and so on.

- The metal, mining and Metallurgy: aluminum powder, lead powder, copper powder ,mineral,alloy powder, electrode powder, manganese dioxide, electrolytic copper powder, electromagnetic materials,abrasive powder, refractory material, kaolin, lime, alumina, ground limestone,quartz sand and so on.

- Pollution treatment: waste oil, waste water, dyeing wastewater, additives, activated carbon and so on.

Features---tapioca flour sieving machine

- The efficiency is high, the design is exquisite and durable, any fine kind, the mucus can be screened.

- Easy to change net, easy to operate, easy to clean.

- The mesh is not blocked, the powder can not fly, can screen to 500 mesh or 0.028mm.

- Impurity coarse material automatic discharge, can continuous operation.

- Unique network frame design, the screen was used for a long time, changing the net fast, only 3-5 minutes.

- Small size, space saving, easy to move.

- Screen up to five layers

Exhibition & Customers

Packaging & Delivery

Wooden case or as your requirements

20 days after receipt of your require

1. How to choose the machine?

a: Customers who are familiar with technical performance and parameters can directly order.

Note: You had better send us the pictures you have ever used.

b: Customers who need us to choose the models, please follow the information, tell us:

• Name and feature of the raw material?

• Aim of using: get rid of impurity, filtration, grading

• Handling capacity: kg /h, L/h

• The raw material size: (mesh or mm)

• How many final materials you want, or how many layer you need?

Note: You had better send us the relevant pictures about the details.

2.How many kinds of material are supported?

• All stainless steel (304, 316L)

• All carbon steel Q235

• Contact part Stainless steel

3.Is it special requirement available?

Packaging & Delivery

Wooden case or as your payment

20 days after receipt of your require

This machine also could be customized by clients' specific production line requirement.

Welcom your telphone or E-mail at anytime,we will give the answer soon.

China

China