Our Company

Xinxiang Xianchen Vibration Machinery Co,. Ltd ,which is established in the year of 2009, located in China biggest machinery manufacture base Henan province, is a professional vibration machinery manufactures which specializes in the production of sieving equipments, conveying equipments, crushing equipments and feeding equipments as well as relevant parts. we committed to solve all kinds of sieving problem.

Our tenet: "market oriented, technology based, quality of survival, innovation and development ".We have passed ISO9001:2008 certification. Under the guide of international quality management system, our products have won not only good reputation in china but also applauses by foreign clients like United States, Germany, Turkey, Indonesia and so on.

Why Choose Xianchen

1) International high quality certification product chain

2) Manufacturer, more reasonable price

3) Solid technical support and after-sales service

4) Uphold the principle of “Customer Supreme”

5) Exports to more than 20 countries and regions, good customers feedback

6) One-stop service, customized exclusive project feasibility report.

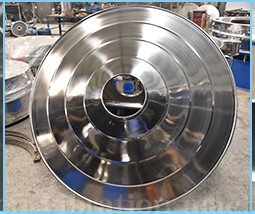

Brief Introduction - Rotary vibrating screen

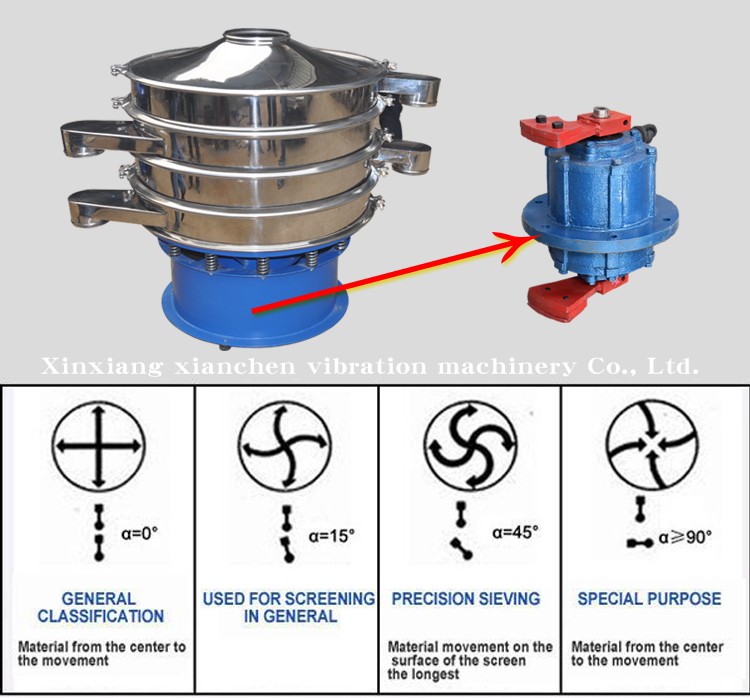

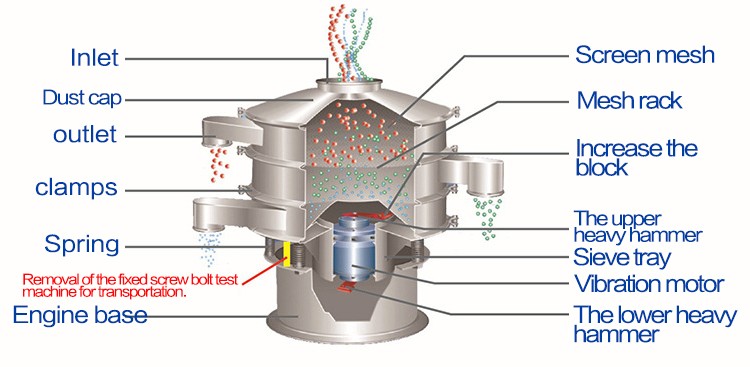

Rotary vibrating sieve is designed as a high-precision screening machinery. Electric vibrating sieve is composed of vertical motor,and eccentric weight installed at two ends.We can produce horizontal, vertical, inclined motions by adjusting the upper and lower eccentric weight.Diameter can be ranged from 400mm to 2000mm, with single or multiple screening decks(1-5 layers).Material can be divided into all carton steel,contact part stainless steel and all stainless steel.

Working Principle - Rotary vibrating screen

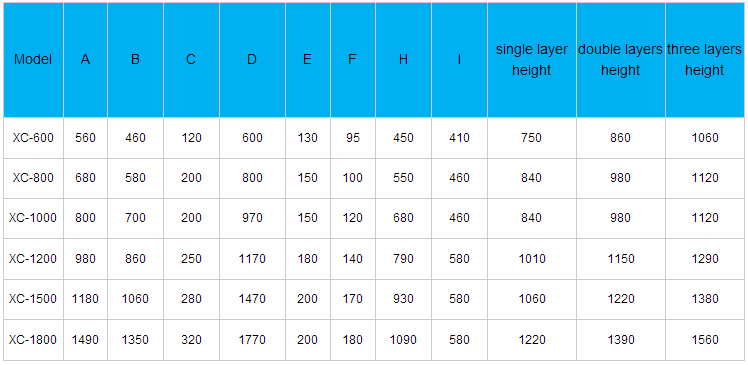

XC series vibration screens use upright motor as the vibration source, with eccentric hammers on the both ends, which makes the processed materials jump in a 3-dimensional movement path on the screen surface. The movement path can be changed by adjusting the phase angle between the two eccentric hammers.

Features - Rotary Vibrating Screen

1. High efficiency, elegant design and durable, available for any powder.

2. No jam for screen net, and no powder flying around and no liquid leaking out.

3. The screen nets are uniquely designed under 500mesh.

4. Quick change screen net in less than 5 minutes.

5. Stainless steel parts contacting materials.

6. Easy to operate, impurities and coarse materials can be discharged automatically.

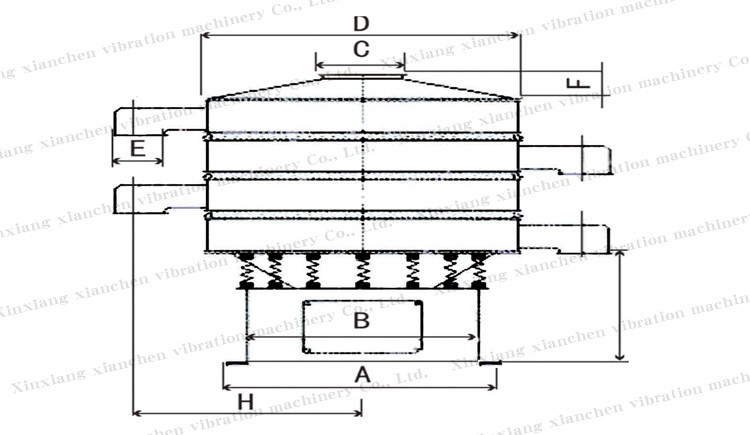

Technical parameter - Rotary vibrating screen

| Model | Power(KW) | Screen dish(φ) | effective area(m²) | Layer |

| XC-600-1S XC-600-2S XC-600-3S | 0.25 0.55 0.55 | 560 | 0.2375 | 1 2 3 |

| XC-800-1S XC-800-2S XC-800-3S | 0.55 0.75 0.75 | 760 | 0.4416 | 1 2 3 |

| XC-1000-1S XC-1000-2S XC-1000-3S | 0.75 1.1 1.5 | 930 | 0.6789 | 1 2 3 |

| XC-1200-1S XC-1200-2S XC-1200-3S | 1.1 1.5 1.75 | 1130 | 1.0382 | 1 2 3 |

| XC-1500-1S XC-1500-2S XC-1500-3S | 1.5 2.2 2.2 | 1430 | 1.6052 | 1 2 3 |

| XC-1800-1S XC-1800-2S XC-1800-3S | 2.2 2.2 3.0 | 1730 | 2.3523 | 1 2 3 |

Machine Parts

Machine Parts

Machine Parts

Name: Fast locking ring

Origin: XC

Feature: It use a unique v-shaped reinforced lock clamps and professional net frame, more secure, more strong.

Machine Parts

Name: Vibrating motor

Origin: XC

Feature: It is a high-performance vertical vibration motor, to provide you with the surging power, support for a long time uninterrupted work.

Application - Rotary vibrating screen

1) Size classification: separation of particles into groups of comparable size from the materials.

2) Gravity filtering: removal of solids from liquids and slurries.

3) Product reclamation: removal of the solids from waste product or clarification of waste liquor for further use.

4) Screening: separation of a few oversize particles from a quantity of materials.

5) Liquid cleaning: cleaning of wastewater or removing the solids from recirculation liquid.

Packing & Shipping - Rotary vibrating screen

Packaging Details: The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

Shipping Time: Shipment within 15 days after receipt of payment .

1. Pre-sale service:

a. In order to let each customer know better about the performance and requirements, we provide these services

b. To send each potential customer the detailed production information and company profile

c. According the user’s different needs, we work to recommend and guide for them

d. To help them select the appropriate equipment

2. Service during sale:

a. Do good communication with customers, so that each part can exchange the information.

b. Deliver on time as per the contract clause.

3. After-sale service:

a. To track the customer’s feedback after receiving the equipment

b. Any product quality we receive, the technical personnel will guide to solve the problem

c. All the products have three guarantees

d. Provide technical exchanges

e. Do well about the work of maintenance and service

1.How to choose the machine?

a: Customers who are familiar with technical performance and parameters can directly order.

Note: You had better send us the pictures you have ever used.

b: Customers who need us to choose the models, please follow the information, tell us:

• Name and feature of the raw material?

• Aim of using: get rid of impurity, filtration, grading

• Handling capacity: kg /h, L/h

• The raw material size: (mesh or mm)

• How many final materials you want, or how many layer you need?

Note: You had better send us the relevant pictures about the details.

2.How many kinds of material are supported?

• All stainless steel (304, 316L)

• All carbon steel Q235

• Contact part Stainless steel

3.Is it special requirement available?

This machine also could be customized by clients' specific production line requirement.

China

China