PGZ Automatic Peeler Bottom Discharge Basket Centrifuge

PGZ Vertical Automatic Scraper Bottom Discharge Pharmaceutical Separating Centrifuge

PGZ Automatic Peeler Discharge Centrifuge

PGZ Full Automatic Bottom Discharge Filter Centrifuge

Working Principle :

Adopt PLC control ,the procedure setting in advance, automatic completing these operation : early feeding , filtering/dewatering/separaion , washing , refiltering , discharging .

PGZ Automatic Peeler Centrifuge

Main features:

1. PLC control, full automatic operation

2. AC motor controll the speed stepless, stable starting, adjustable separation factor.

3. The braking energy, non-contact braking mode, no friction dust pollution.

4. Fully sealed structure, sealers adopt silicon rubber, or fluorine rubber, centrifuge lumen nitrogen protection, which can realize airtight explosion-proof requirements.

5. Reasonable structure design, online cleaning system (sprinkler system), to ensure the cleanliness requirements, and meet with the GMP

6. Automatic movement components adopt pneumatic system, make the machine more clean.

7. Optional gas scraper to control the discharge with no residual filter cake in the drum.

8. No base installation, simple structure, beautiful appearance, convenient cleaning.

9. Safety protection: speed detection, vibration protection, open cover protection, motor overload and overheat protection, scraper rotating, lifting machinery electricity gas dual control, the linkage locking of scraper and the basket

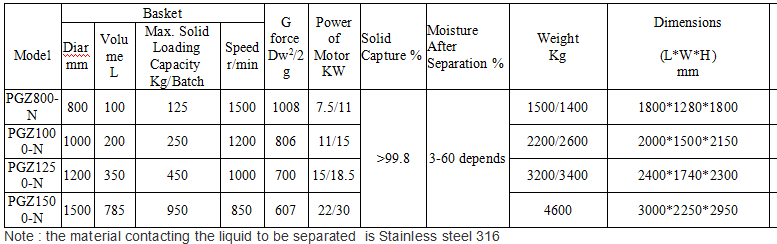

Technical parameter:

Application:

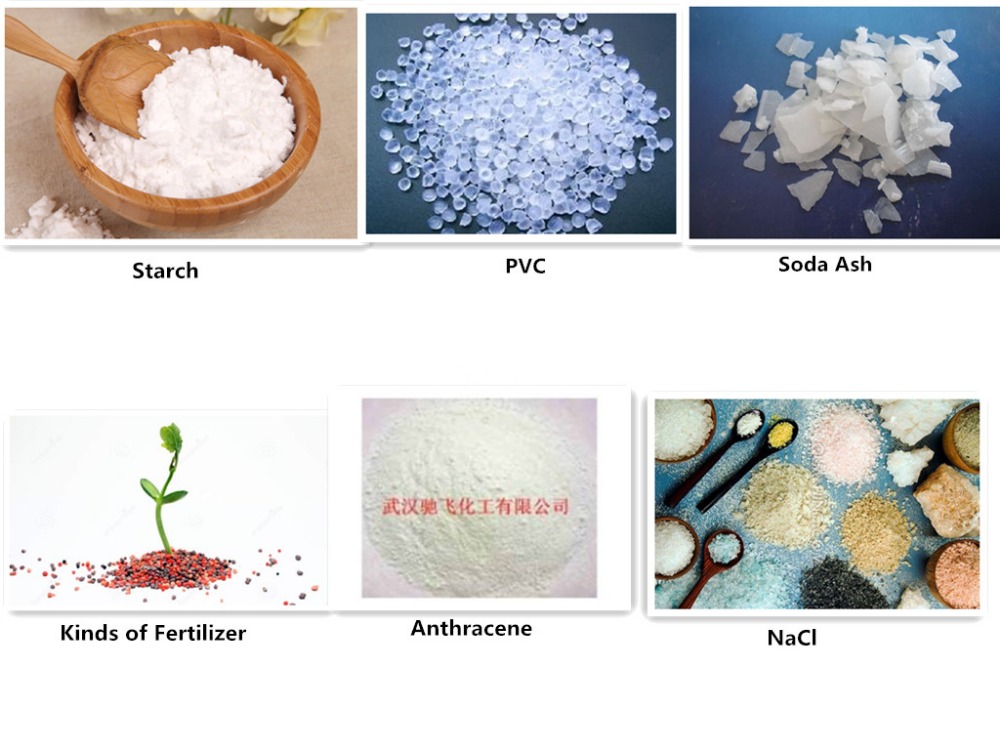

Apply to separate the suspended liquid , the solid can be powder, granular, crystal and fibrous. and the diameter of the solid larger than 0.01 mm. it also applies to dewater the work pieces like yarn, textiles and so on.

1.Chemical Industry: gypsum, thiamin, salt, ferric sulfate, boric acid, borax, rubber additive, dye, and other chemical products.

2.Food industry: kitchen salt, sodium glutamate, food additive, Chemical seasonings, sugar

3.Pharmaceutical:Extraction of vitamin, biotic, traditional Chinese medicine and other various drugs

4.Mine and Metallurgy: Copper, zinc, minerals, and metal refining

5. Environmental Protection: with acid discharge, pure water sludge and sewage sludge, etc

China

China