Cheap China Factory Suspended Batch Centrifuge

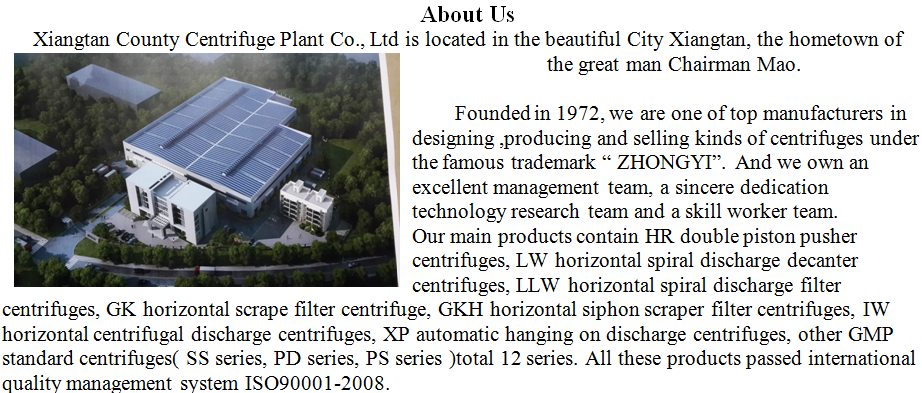

Application

Application

Apply to separate (dehydrate ) the suspension , the solid can be powder, granular, crystal and fibrous. and the diameter of the solid larger than 0.01 mm. it also applies to dewater the work pieces like yarn, textiles and so on.

1.Chemical Industry: gypsum, thiamin, salt, ferric sulfate, boric acid, borax, rubber additive, dye, and other chemical products.

2.Food industry: kitchen salt, sodium glutamate, food additive, Chemical seasonings, sugar

3.Pharmaceutical:Extraction of vitamin, biotic, traditional Chinese medicine Amino acids, antibiotics, pesticides, herbicides and other various drugs

4.Mine and Metallurgy: Copper, zinc, minerals, and metal refining

5. Environmental Protection: with acid discharge, pure water sludge and sewage sludge, ect

Working Principle

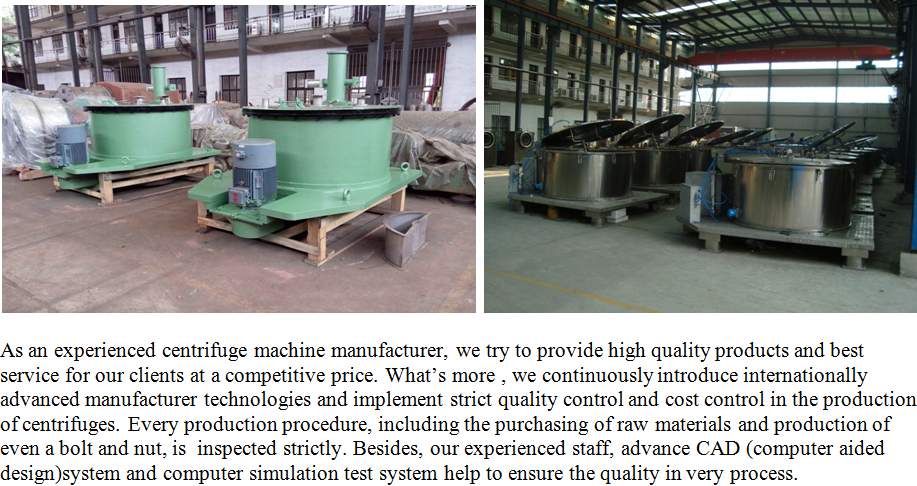

PD series centrifuge is a bag-lifting discharge patch operation filter centrifuge

Once the materials to be separated enter the fast-spinning and distributed on the wall of the basket, it will be filtrated by the filter liner under the centrifugal force.but the solids deposit on the internal wall of the basket. Once the solid cake reach the rate capacity,feeding stop, Clean the solids cake, and then drain out the washing water. stop the machine. For SD, PD series, open the cover, using the filter liner lifting tool pull out the filtering liner with solid cake, and take to the discharging place. Open the bag and take out the solid cake. Put the liner back to the machine for the next batch.

Features

1 Shockproof : To meet more needs, PD series are improved on the base of SD series. we choose the eslatometic damper instead of the traditional three column type support , so no need to install the shockproof equipement on the ground when the machine is working , and it will not cause any noise.

2 Thoroughgoing discharge and easy clean: high quality filter bag make the dicharge more throughoutgoing and matching cleaning spray system , support for CIP/SIP cleaning.make sure of the grade A clean.

4 Nitrogen protection system to ensure that the air of inner isolates from that of outside.And leak -proof structure with silicone rubber or fluoroelastomers searl ,available applied to poisonous, flammable and explosive enviroment.

5 Quick-open type of cover:,Automatic CIP system control the cover open and close .

6 Available speed stepless adjustment mode : Inverter stepless startup, smooth starting, adjustable relative centrifugal force.

7. High efficiency :Discharging solids from suspended bag is highly efficient with low labour intensity. No damage to the particles. Wide range applications.

8. Clean easily :Well-designed structure leaves no place depositing dusts and makes the machine clean easily. The modules are designed smoothly and polished on the surface. The case, fixing parts and drums are made of stainless steel. With hinged enclosure cover, it is easy to clean the gap between the case and the drum.

8. Large Capacity : Bag-lifting discharge and automatic online washing system cleans the internal wall of the cake, the drum and liquid slot to meet the clean requirements in accordance with GMP standards.

9 All these design and function meet tthe GMP standards.

Technical parameter

Model | LD800-N | LD1000-N | LD1250-N | LD1500-N |

Dia of Basket mm | 800 | 1000 | 1250 | 1500 |

Height of Basket mm | 400 | 500 | 600 | 720 |

Speed of Basket r/min | 1500 | 1200 | 1000 | 850 |

Working Volume L | 100 | 200 | 350 | 785 |

Max Solid Loading Capaity Kg | 125 | 250 | 450 | 950 |

Power of Motor kW | 7.5/11 | 11/15 | 15/18.5 | 22/30 |

L×W×H mm | 1750(1300)×1250×1180 | 1950(1550)×1500×1350 | 2200 (1750)×1700×1500 | 2560×2050×1700 |

Net Weight Kg | 1500(1400) | 2600(2200) | 3400(3200) | 4800 |

Function | Solid liquid separation ( dehydration) | |||

| Water content after the separation( dehydration) | 2 %- 50% depens on the solid concentration |

Standard matching

1,Structure : adopt the chamshell matching feeding pipe, washing pipe,observation mirror,exhaust hole, lamp hole, seal structure, and the basket, the shell all made of stainless stell ( SUS 304) , while the base is casting with outside paiting

2,All of the fansteners are made of stainless steel

3, Transmission and braking : General motor( explosion proof motor) +inverter+ dynamic

Optional Matching

1 Washing spray system

2,Nitrogen protection system

3,No base installation ( no base chassis and damping)

4,All the shell is made of stainless steel

5 The materials contacting the liquid to be separated can be SUS 304/316/316L/321/Ti

6,Transmission and braking:

1) General motor (explosion proof motor) + automatic clutch +mechanical braking

2 ) Electromagnetic speed adjusting motor + mechanical braking

1.What’s the application of centrifuge?

This machine is widely used in many fields such as environmental, pharmaceutical food, chemical industry for separation/washing/dewatering . It can separate almost all liquid and solid with proper feature.

2.How to clean the machine?

The machine has self-cleaning function. When the processing is finished, you just put one button and the machine will do the cleaning automatically.

3. How to choose the machine material?

For the material, we have stainless steel 304, 316 and 321 for your option. Generally SS304 is used. If there’s suspension with corrosion, then SS 321 /316 or Ti is needed.

4.What’s the capacity of the machine?

Firstly we have different model with different capacity for this machine.

Secondly, the capacity will be customized according to concentration of the suspension. Higher the concentration, lower the capacity.

5. How is the processing result?

The finished cake moisture and solid lost rate is based on the material feature. And different machine just brings different processing capacity. Also we can offer testing service to get realistic results.

Cheap China Factory Suspended Batch Centrifuge

China

China