Top Quality Custom And Special Industrial Good Quality Decanter Centrifuge

Applications:

It is applicable for two-phase (solid-liquid) separation and three-phase (solid-liquid-liquid) separation in the chemical, pharmaceutical, environmental protection, mining, food and other industries.

1. Oil &gas drilling mud/fluid control

2. Industrial and municipal wastewater treatment

3. Fine Chemical slurry

Classification and dewatering for dyestuff and pigment

4. Coal and minerals (float wash of extractive coal and dewatering of coal mud)

Separation and purification for coal far

Classification and dewatering for minerals

5. Pharmaceutical industry (antibiotic)

6. Food processing

-Production and extraction for Olive oil, palm oil, avocado oil;

Clarification and purification for animal oil and vegetale oil

-Clarification and purification for Wine, fruit juice;

-Washing, classification and dewatering for Starch; Surimi ;

-Dewatering for Soybean and wheat protein

Dewatering for grains

-Dewatering for Shellfish

Working Principles

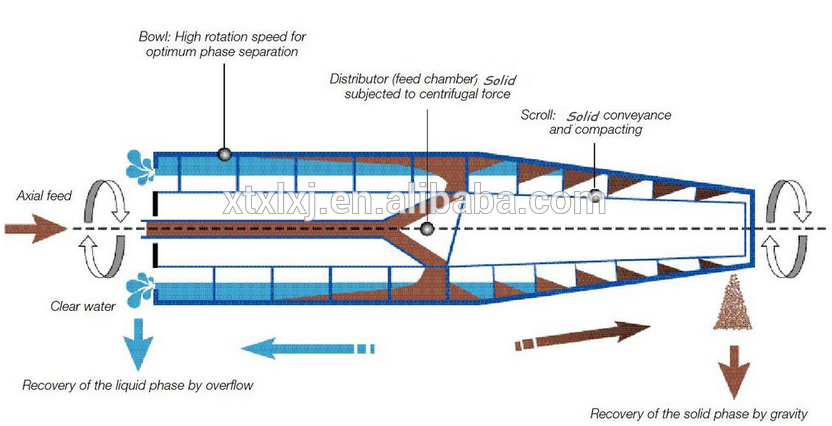

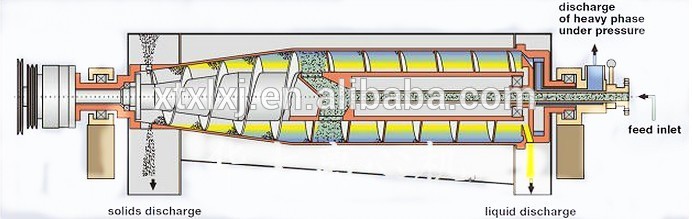

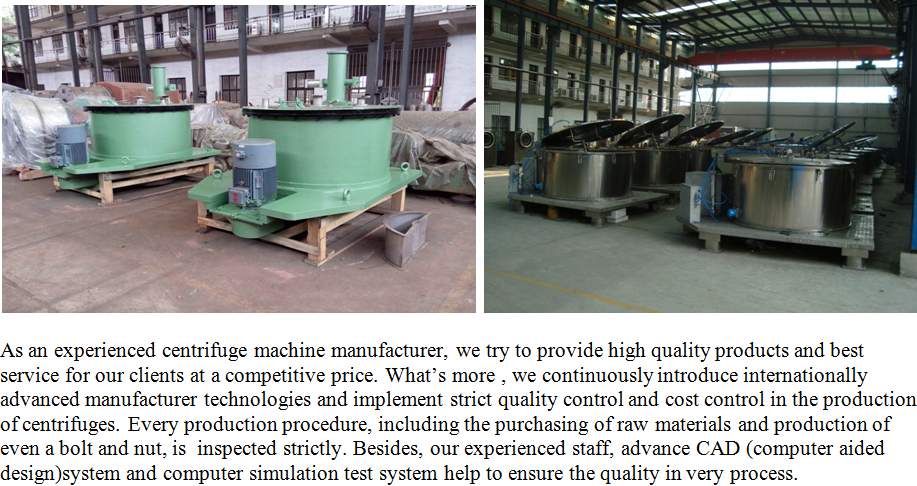

LW series Two Phase Horizontal Separation Decanter Centrifuge ( LWS three phase separation decanter centrifuge )are main composed by high speed bowl, discharge spiral, differential mechanism, shell, bearing room, base motor and other parts

Types of LW(LWS) decanter centrifuges

Clarification and purification

Inspissation

Dehydration

Classification and extraction

When the motor drives, the materials to be separated fed into the bowl at high speed. Under the action of the strong centrifugal force, the materials form the annular flow and the solid phase stay on the wall of the bowl, and the solid phase becomes solid cakes, as the speed of the bowl is different from that of the spiral, that means relative movement, by the movement the solid cakes go into the drying section and continuously dewater , then move out the machine ( centrifuge), at the same time, the clear liquid phase move out from other exit.

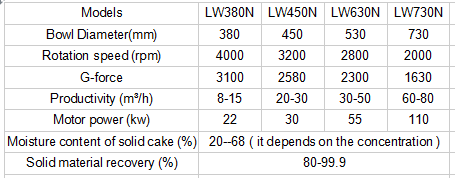

Techincal Parameter for 2 Phase Solid liquid Separation Decanter Centrifuge

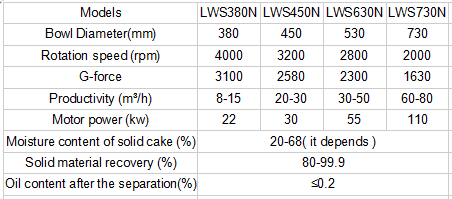

The Parameter for 3 Phase Solid liquid liquid Separation Decanter Centrifuge

Working Condition

1 The materials to be seprated are suspend liquid ,solid-liquid and so on .

2 There are density contract of the suspended liquid

3 The range of the concentration: 1- 45% and the particle < 5 mm

4 Working temperature: no more than 110 c

Feature

1Weld hard alloy or spray hard alloy for wear protection

2 Full automatic and sealed continuously operation make the maintenance more easlier less cost

3 Larger output capacity

4 Compact design and saving room

waste water treatment

Sludge/mud dewatering

Juice extraction and purification

1.What’s the application of centrifuge?

This machine is widely used in many fields such as environmental, pharmaceutical food, chemical industry for separation/washing/dewatering . It can separate almost all liquid and solid with proper feature.

2.How to clean the machine?

The machine has self-cleaning function. When the processing is finished, you just put one button and the machine will do the cleaning automatically.

3. How to choose the machine material?

For the material, we have stainless steel 304, 316 and 321 for your option. Generally SS304 is used. If there’s suspension with corrosion, then SS 321 /316 or Ti is needed.

4.What’s the capacity of the machine?

Firstly we have different model with different capacity for this machine.

Secondly, the capacity will be customized according to concentration of the suspension. Higher the concentration, lower the capacity.

5. How is the processing result?

The finished cake moisture and solid lost rate is based on the material feature. And different machine just brings different processing capacity. Also we can offer testing service to get realistic results.

Top Quality Custom And Special Industrial Good Quality Decanter Centrifuge

China

China