China Supplier Top Grade centrifugal separator for starch industry

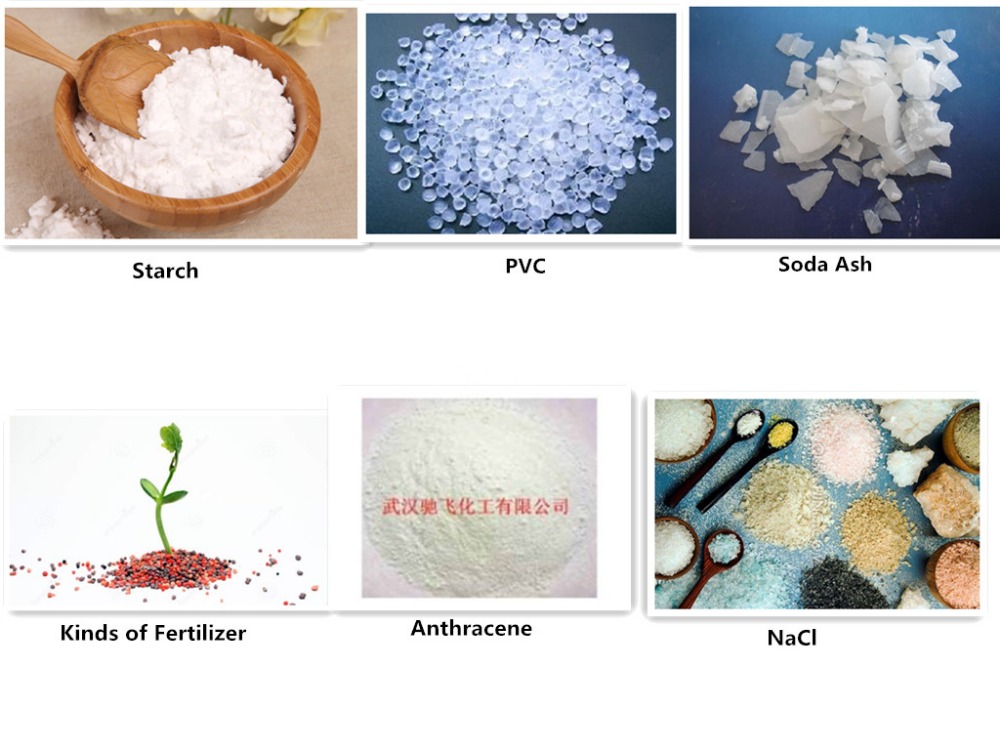

Applications

This machine is used to separate these solid liquid suspension like ammonium sulfate, copper sulfate, potassium hydroxide, zinc sulfate, soda, citric acid (salt), magnesium sulfate, fumaric acid, sugar, sugar alcohol, cologne acid, ammonium sulphate and other solid-liquid separation

Working Principle

LLW Series is kind of horizontal Spiral Discharge and Continuous Operation Filter Centrifuge.

The motor drives the basket as well as the feeding spiral in the same vertical line at different high speed. The materials to be separated go continuously into the feeding pipe and distribute on the wall of the bowl, under the action of the centrifugal force, the liquid goes through the bowl, while the solid staying the bowl form the filter residue . and it goes continuously through the basket and move out of the machine under the combined action of the conic surface component force of the centrifugal force and the spiral feeding pipe.

Features

LLW series are capable of the continuously operation of feeding, separating, washing and discharge at full speed.

1. compact structure,

2. minute extension

3. Continuous operation

4. Stepless speed

5. High load capacity

6. Wide range of application

7. Low moisture content in the filter cake

Working Condition

1 The materials to be seprated are suspend liquid ,solid-liquid and so on .

2 There are density contract of the suspended liquid

3 The range of the concentration: 10- 80%, and the diameter of the solid phase is 0.1-5mm

4 Working temperature: no more than 100 c

Optional Parameter

1 Material contactedthe liquid to be separated : Carbon steel(G), Corrosion resisting steel (N), Titanium(I), Metal coat (J), Rubber ,and so on

2 Motor Type: General motor or explosion proof motor

3 Speed controller: AC frequency , electromagetric or mechanical belt

4 The range of speed difference: 10 r/m - 50 r/m

5 Discharge: Mother liquid and washing solution can be discharged mixed or separately

6 All the machine made match the GMP standard

7 Design and produce all customized

Techincal Parameter

Model | Dia of Basket(mm) | Speed of Basket(r/min) | G.Force | Outpur Capacity(m3/h) | Main Motor(KW) | Net weight(kg) | Dimension(L*W*H)(mm) |

LLW320 | 320 | 2630 | 1240 | 0.5~3 | 7.5 | 700 | 1350*1050*1000 |

LLW350 | 350 | 3000 | 1770 | 1~5 | 11 | 1200 | 1520*1140*1080 |

LLW450 | 450 | 2500 | 1580 | 2~8 | 22 | 1700 | 1640*1380*1190 |

LLW530 | 530 | 2000 | 1190 | 3~10 | 30 | 2500 | 1680*1390*1340 |

LLW630 | 630 | 1800 | 1140 | 5~15 | 37 | 3500 | 2110*1560*1650 |

LLW800 | 800 | 1400 | 870 | 8~20 | 55 | 4000 | 2300*2200*1750 |

LLW1000 | 1000 | 900 | 445 | 10~50 | 75 | 6200 | 3200*2155*2280 |

1.What’s the application of centrifuge?

This machine is widely used in many fields such as environmental, pharmaceutical food, chemical industry for separation/washing/dewatering . It can separate almost all liquid and solid with proper feature.

2.How to clean the machine?

The machine has self-cleaning function. When the processing is finished, you just put one button and the machine will do the cleaning automatically.

3. How to choose the machine material?

For the material, we have stainless steel 304, 316 and 321 for your option. Generally SS304 is used. If there’s suspension with corrosion, then SS 321 /316 or Ti is needed.

4.What’s the capacity of the machine?

Firstly we have different model with different capacity for this machine.

Secondly, the capacity will be customized according to concentration of the suspension. Higher the concentration, lower the capacity.

5. How is the processing result?

The finished cake moisture and solid lost rate is based on the material feature. And different machine just brings different processing capacity. Also we can offer testing service to get realistic results.

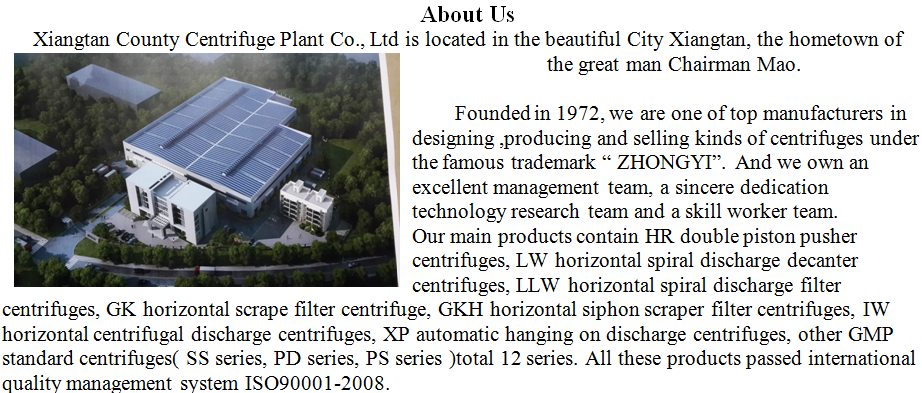

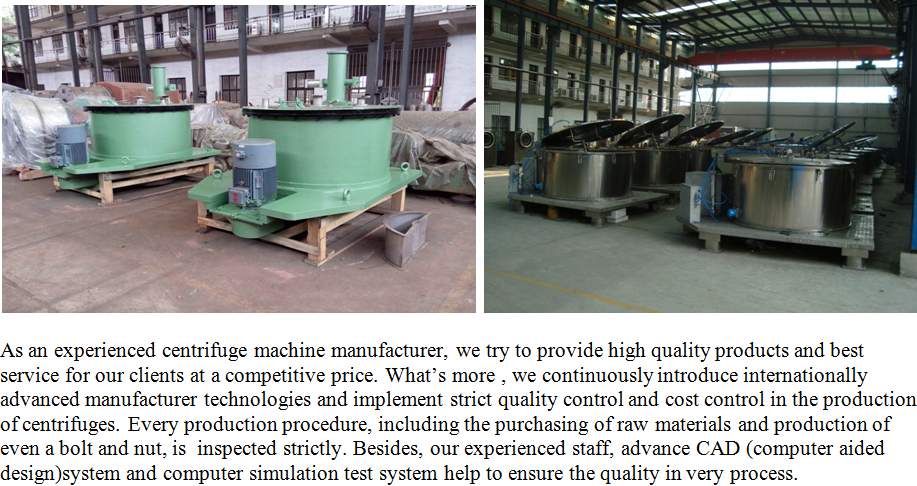

China Supplier Top Grade centrifugal separator for starch industry

China

China