Nozzle type DPF Starch Centrifuge Separator for Corn Starch

DPF disc separator widely absorbed international advanced separator technology and independent researched by uniting domestic starch technology in actual situation. It is meticulous designed by technicists with rich design experience in our company.

Advantages of Starch Centrifuge Separator

1,Big diameter of drum, large area of disc, strong capability of production(separation),excellent effect of separation.

2,Adopting top-suspension driving, which makes the separator with high rotation stability, and largely improves the using life of bearings and main shaft.

3,Adopting automatic control of lubricating oil circuit, which protects and prolongs the using life of driving system.

4,Adopting big nozzles, which has big feed capability, reduces the chances of block, assuring the continuous production.

5,Fitted with hydraulic system for lifting drum, which makes more easily to check the drum and replace the nozzles.

6,The material of drum adopts imported high-strength corrosion-proof stainless steel, which assures the safety and stability of separator.

7,This machine can be started up when no-load.

8,This machine can treat the materials with various concentration without internal adjustment.

9,Fitted with inner circulation system, which keeps the stability of separation and good to adjust andcontrol accurately.

10,Easy to operate, workers can grasp the operation instruction in a short time.

Our Company

Henan Huatai Cereals And Oils Machinery Co.,Ltd. was founded in 1950,whcih is a large-scale oil machinery manufacturing enterprise integrating R & D, design, manufacture and installation as one of the major grain and oil machinery manufacturing enterprises in China.Our company headquartered located in Huaxiang County Industries,Henan Province,China,covering 100,000.00 square meters.

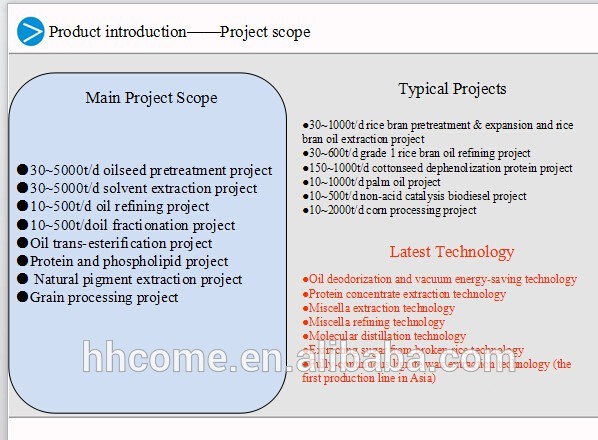

Huatai machinery has developed projects including large scale oilseed pretreatment and pressing, oil extraction, oil refining and oil fractionation production line project,conveyor equipment project,corn/maize flour, grits, germ milling machines and corn processing lines,biodiesel technology,cottonseed, rice bran and soybean protein technology, and Palm Oil processing lines,etc.

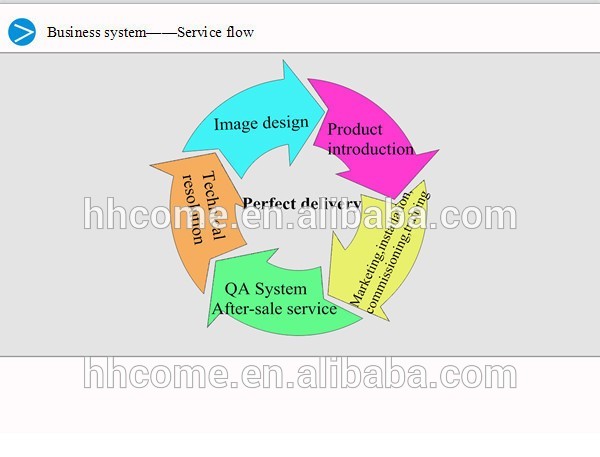

Our company always put the interests of customers and product quality to the first place, and always adhere to the"no best, only better" as our purpose. We will be commitment to provide high quality products with perfect site services and after-sales service. Now the specific commitments are as follows:

field installation debugging.

8. After the equipment field assembly and installation, we will be also responsible for the single equipment debugging, online debugging and Feeding trial operation,to ensure that equipments can normal operate in full load conditions. We will provide all kinds of information and records according to the requirements of the bid.The qualified completion files will be provided to customers according to their requirements within one month after acceptance.

9. In the warranty period, all because of the quality of products has caused the damage or failure of

equipment,suppliers will take the responsibility for the free repair and replacing spare part.

Due to the damage caused by the customer,we only charge material costs for repair and replacement. After the receipt of customers notice,we will suggests the method to solve problem within six hours,or send specialist to the site to solve the problem within twenty four hours.

Contact us

China

China