soybean oil Making Processing Machine Line

Ken Wang | Trade Manager

Mobile: +0086-18203651296 Email:sales09(at)oilmachineworld.com

Skype: huatai-sales09 Web:www.oilmachineworld.com

Soybean oil is one of the most important primary foods and therefore requires maximum quality. The quality of the final product depends on the refining method and the nature of the crude oil. HUATAI provide "Turnkey Service" for customer ; soybean oil solvent extraction machinery

Processing of e. g.

• Soybean oil • Rapeseed oil • Sunflower oil • Animal fat • Cottonseed oil • Corn oil • Fish oil

Our core competence in edible oil refining

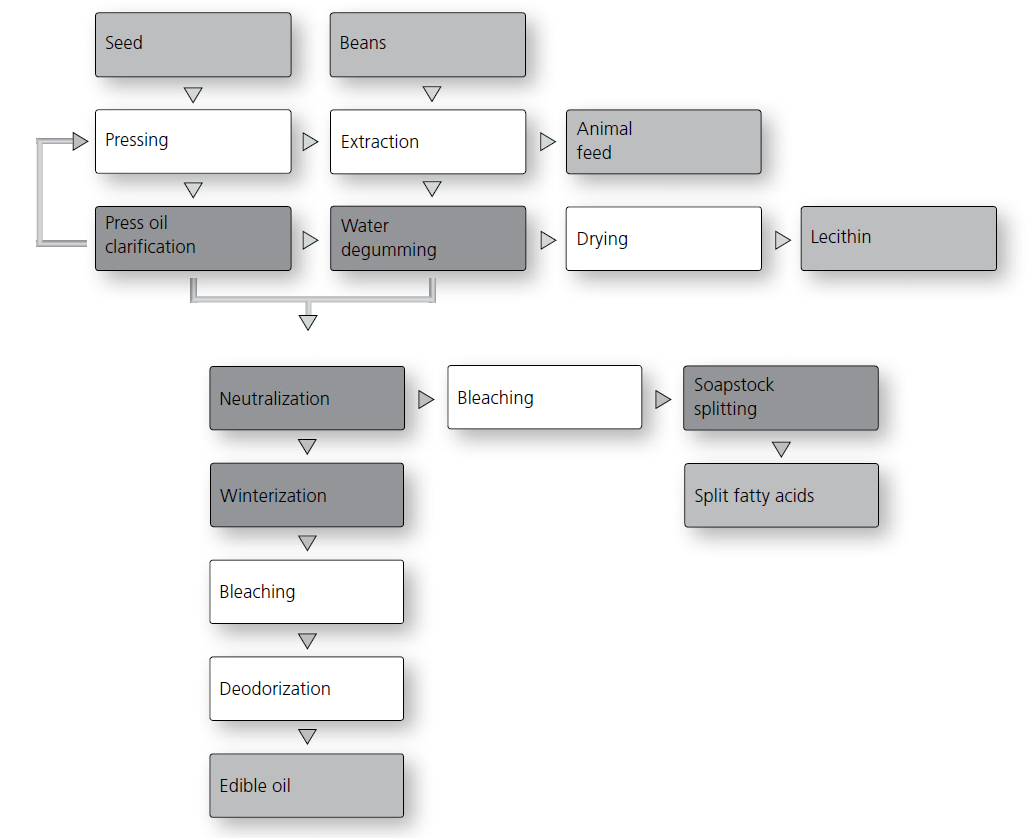

• Press oil clarification • Degumming • Neutralization • Dewaxing • Fractionation • Soapstock splitting

soybean oil Making Processing Machine Line ,Chemical refining

Two processes have been developed for refining edible oils and fats; the decision as to which process is to be used depends on the types and qualities of crude oil to be processed.

Chemical refining is the traditional method, where the free fatty acids of the crude oils are neutralized with caustic soda. The resultant sodium soaps are separated by means of separators. The neutral oils are subsequently bleached and deodorized. This method can be used for reliably refining virtually all crude

oils, including oils of low quality, with the exception of castor oil.

- Clarification of Press Oil

The oil which is discharged from expeller presses has various solid content levels depending on the oil seed type and the condition of the press. In order to remove particularly large solid particles, the oil is usually fed into a settling tank, which is also used simultaneously as a buffer tank. In some installations, a vibrating screen is used for precleaning, or the oil is taken directly from the press to the press oil clarification unit.

- Water Degumming

A smooth action pump is used for conveying the crude oil to a heat exchanger, which is used for heating the crude oil to the optimum process temperature. A quantity of hot water corresponding to the content of phosphatides in the crude oil is added to the oil and mixed intensively. A special dynamic mixer, which simultaneously conveys the oil directly to the separator, is used for this purpose. The hydratable phosphatides swell immediately due to the particularly intensive mixing of oil and water, and no additional reaction time is necessary.

- Acid Degumming

This degumming method is suitable for pretreating palm oil, palm kernel oil, coconut and olive oil as well as animal fats with the aim of reducing bleaching earth consumption in the physical refining process. This considerably improves the economy of this method.

- Neutralization

This method is suitable for neutralizing predegummed edible oils or oils which originally only have a low phosphatide content. The free fatty acids are saponified with caustic soda, and the sodium soap is separated.

Henan Huatai Food & Oil Machinery Engineering Co., Ltd. (short for HHFOME) is a manufacturing enterprise specialized in producing oil machinery in China. HHFOME consists of Henan Huaxian Grain Machine Factory, Huaxian Hangpeng Grain Machinery Co., Ltd. and Beijing Huakang Xiwang Biological Technology Co., Ltd.. Established in 1988, HHFOME covers an area of 63,000 square meters and has 210 senior engineering technicians. Our company has 202 sets of automatic processing equipment. Processing capacity of our enterprise is more than 3000 sets every year.

HHFOME has obtained independent export rights and has passed the evaluation of ISO9001:2000 Quality System Management Certification. We have got 22 national patents, 4 international awards, 2 national awards and 2 provincial awards.

Our products include copra oil pressing equipment, rice bran oil manufacturing equipment, lignite wax extraction equipment, cottonseed preprocessing equipment and other machinery of oil making field, with 5 series and over 80 kinds.

Our Main Products:

Sets of equipment for rice bran oil making, set of equipment for palm oil fractionation, sets of equipment for cottonseed protein dephenolization, biodiesel continuous production equipment, large scale high-class cooking oil equipment, Class A oil refining equipment, JC-plate extraction equipment and oil filters

Turnkey Service of soybean oil Making Processing Machine Line

China

China