Jiangsu Zhenxing Drying Equipment Co.,Ltd

specialized in development, manufacturing, and installation of dryers, mixers, granulators, grinders, conveyors, sieve and etc. We are certified with ISO9001 quality management system. We follow a strict quality control procedure and we provide high quality products with prompt after sales services and technical supports. Our products have been exported to North America, Pakistan, India, Philippines, Thailand, Nigeria, South Africa, Mexico, Colombia, Australia, Egypt, Vietnam, Russia, and other countries.

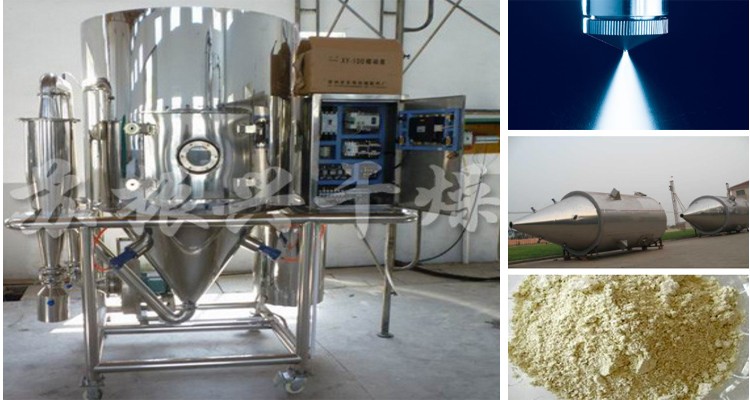

LPG cow blood powder Centrifugal Spray Dryer drying equipment on sale

DESCRIPTION

The spray drying technology is the widest used in the liquid shaping technology and in the drying industry. It is most suitable for producing powder, particle, or block solid products from materials of solution, emulsion, soliquoid and pumpable paste states. Therefore, the spray drying is one of the most desired technologies when the particle size and distribution of the final products, their residual water contents, and the stocking density and the particle shape can meet the precision standards.

FEATURES

1.The drying speed is rapid. When liquid raw material is atomized, the surface of the material will be enlarged greatly. 95% - 98% of water can be evaporated instantly in the hot airflow and the drying is only a few seconds. This dryer is especially suitable to dry the heat sensitive material.

2.The uniformity, flow capability & solubility of the dryer are very good. The finished products have high quality and high-purity.

3.Simple and stable operation, convenient control and debugging, easy to achieve automatic operation.

4.The production process is simple, The dryer can dry the liquid material which contains 40%-60%(90% for special materials) of moisture into powder at once. There’s no need for smashing or sieving after drying so the operational environment is clean and in healthful condition, it also can avoid powder flying in the air during drying process.

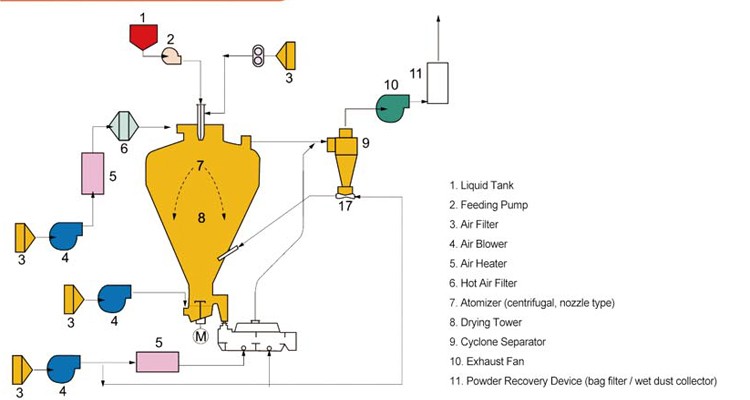

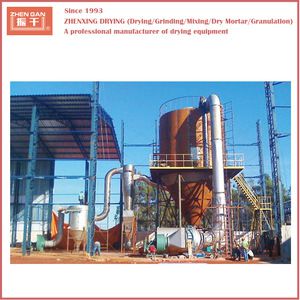

The air enters into the air distributor which on the top of the drier after filtering and heating. The hot air in spiral form equably enters into the drying room. When liquid raw material is passing through the high-speed centrifugal sprayer on the top of the tower, it will be rotated and sprayed into the extremely fine mist liquid beads. Raw material can be dried to the final products instantly while it contact with the heated air. The finished products are discharged continuously from bottom of the drying tower and cyclones segregator. The waste gas is discharged from blower.

Notes:

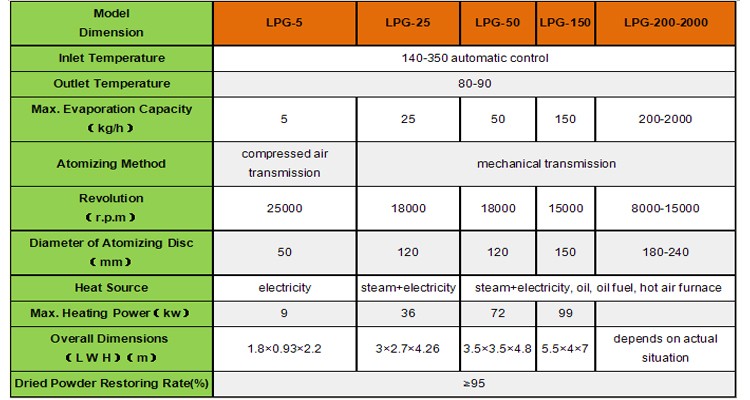

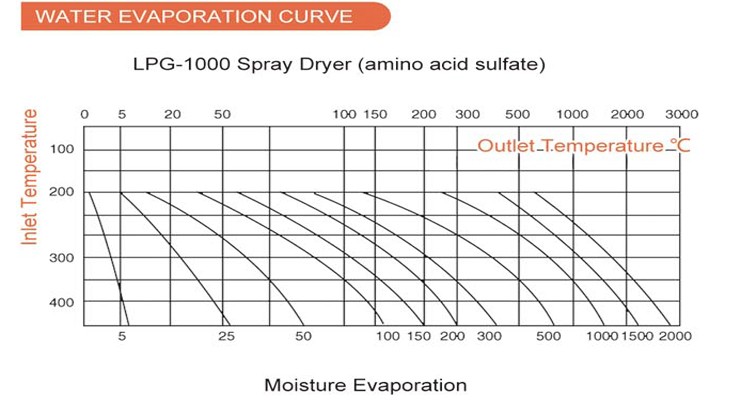

The evaporated amount of water is related to the characteristics of raw materials and the temperature of inlet air and outlet air. When the temperature of the outlet air is 90°C, the water evaporated curve is listed in above table (for reference only). If the product have been improved or updated by new technology, the related parameters will be change accordingly!

Application

Chemical industry:

Sodium Fluoride (potassium), Basic Dyes & Pigments, Dyes Intermediates, Fertilizer, Formic Silicic Acid, Catalyst, Sulfuric Acid Agent, Amino Acid, White Carbon Black, and etc.

Plastic Resin:

AB, ABS Emulsion, Urea-formaldehyde Resins, Phenolic Resins, Urea Formaldehyde Resins, Polyethylene, Polyvinyl Chloride, and etc.

Foodstuff industry:

Lipid-rich Milk, Armpit Protein, Cocoa Milk Powder, Substitute Milk, Hunting Blood Meal, Egg White (Yellow), Chicken Juice, Coffee, Instant Tea, Seasoning Meat, Protein, Soybean, Peanut Protein, Hydrolyzate, and etc.

Sugar: Corn Syrup, Corn Starch, Glucose, Pectin, Maltose, Potassium Sorbate, and etc.

We place customers at the heart of everything we do. Customer satisfaction is a key to our business. We aim to build a long term cooperation relationship with customers by delivering high quality products and superior services. With years of experiences, our products have been exported to North America, Pakistan, India, Vietnam, Russia, Nigeria, Egypt, Yemen, Philippines, Colombia, and other countries.

Recommended Products of International Trade

ISO9001 Certified Enterprise

AQA's Directory of Registered Companies

Design and production

We solicit buyers opinions widely at the design and production stage of equipment; especially at the stage of plan and elevation arrangement, we give full consideration to buyers’ site conditions and public engineering conditions, and pay concurrent attention to the optimum combination when assuring the quality of equipment.

Installation and commissioning

After the equipment is delivered to buyers factory, we will dispatch full-time technical personnel to instruct buyers’ installation and to take charge of commissioning until normal use of the equipment.

Training

Before buyers use our equipment normally, our commissioning personnel will organize buyers’ relevant personnel to accept training, which covers the maintenance and care of equipment, timely repair of common faults, and procedures for operation of equipment.

Warranty

We provide one-year warranty for our equipment. For damage of equipment arising from non-artificial factors within the warranty period, we will provide repair service for free; and for damage of equipment arising from artificial factors, we will provide repair service in time and collect corresponding cost.

Maintenance and period

For damage of equipment after expiration of warranty period, we will provide on-site repair service within 24h/48h for enterprises inside/outside the province after receiving buyers’ notification. The service provided after expiration of warranty period is fee-based, and flat cost will be collected each time when the service is provided.

China

China