Single Double Triple-Effect Falling thin film Evaporator salt water evaporator

Brief introduction:

Forced circulation evaporator consists of heat chamber and evaporation chamber, with a circulation pump liquid circulate in the tube nest, circulation speed can reach 1.5-3.5 meters/seconds, heat transfer efficiency and production capacity is larger, when heated to overheat under higher than normal liquid boiling point, steam and liquid mixture enter into the evaporation chamber, then separate, steam discharge from the upper, liquid is blocked down, through the bottom of the cone, liquid is sucked by the circulating pump, and then enter the heating tube, continue to cycle, secondary steam from evaporation enter into the next effect evaporator heating or into the condenser for cooling.

Forced circulation evaporator is a high efficiency and energy saving enrichment crystallization equipment, the equipment is under the condition of vacuum low temperature operation, fast speed of material liquid fast evaporation, not easily scale features, very suitable for the crystallization evaporation of the salt solution, forced circulation evaporator can be divided into single effect, double, triple effect, and multiple effect forced circulation evaporator.

System structure:

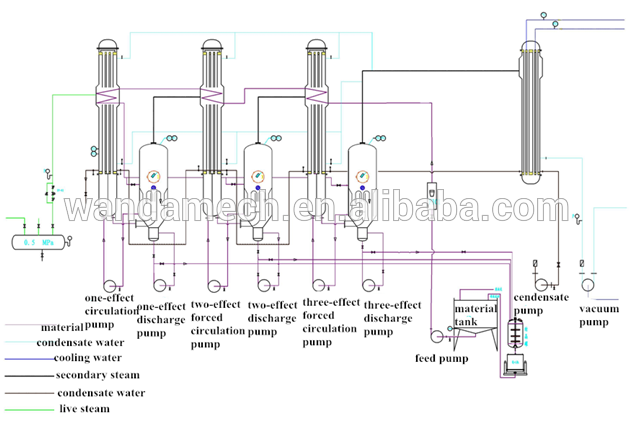

Multiple effect forced circulation evaporator consists of steam header, the heaters, separators , condenser, vacuum system, three effect material liquid pump, condensation water pump, feed pump and operation platform, hand/automatic valves, pipe connection and automatic control system, etc.

Features:

1. The whole set system has reasonable and beautiful design, stable operation, high efficiency, energy saving and low steam consumption.

2. high coefficient of heat transfer, fast circulation speed, short evaporation time.

3. salting-out resistance, fouling resistance, strong adaptability, easy to clean.

4. high concentration ratio, large capacity, make the viscous material liquid easy to flow and evaporate.

5. The materials and liquids are separated after coming into the separator. The effect of separating is greatly improved, and it is flexible to operate.

6. equipment structure is compact, cover small area, the layout is simple and fluent.

7. continuous feeding and discharging, the liquid level and density of the material liquid can be realized automatic control.

Scope of application:

Forced circulation evaporator is suitable for the fouling resistance, crystallization, thermal sensitive (low temperature), high concentration, high viscosity and insoluble solids such as chemical industry, food, pharmaceutical, environmental protection engineering, waste liquid evaporation recycling industries of evaporation concentration.

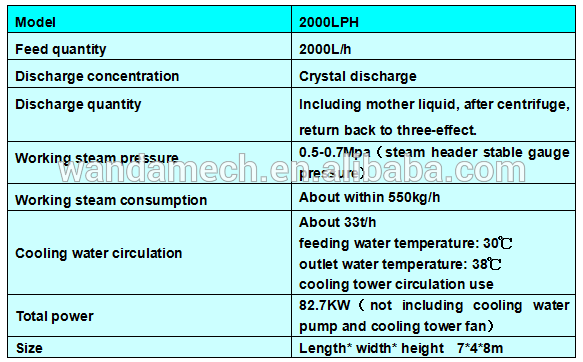

Product technical parameter:

Product picture:

Single effect

Double effect

Triple effect

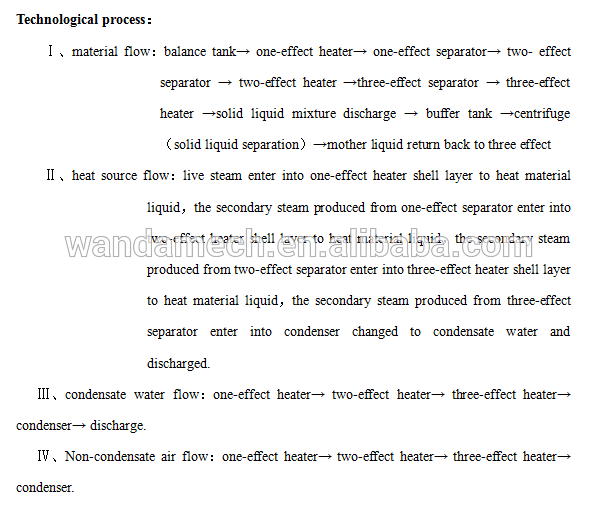

Flow process:

1.We will provide one-year warrantee to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.

2. Consultant services for whole machine life, 24 hours technical support by email and telephone.

3.Send technicians to the jobsite for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

LIAOYANG WANDA MACHINERY CO.,LTD is specialized in design, development, manufacture and sale of pharmaceutical, chemical and packaging machinery.Our products include filter, centrifuge, mixer, tablet press machine, granulator, dryer, packing machine, teabag packing machine, etc.

Other feature products:

Contact us:

China

China