Solid -Liquid And Suspended Solid Sedimentation Centrifugal Separator Equipment And Device

Product Scope:

The model for the large solid content in feed solution, fine particles, but also difficult to filter the nature of manufacturing high density difference between a use state of separation equipment can be used alone, but also as a tube pre-treatment process separator the use of centrifuges in operation and linked to contrast and cup, such as bowl speed and the same diameter, ther aircraft has a large capacity, the advantages of simple operation.

Product features:

Structural design is reasonable and effective to eliminate the health corners, structural parts smooth transition, the surface polished, external components, fasteners, and with the material contact parts are made of stainless steel shell for the clamshel can be laminated on the centrifuge hosing and drum of cleaning space.

Base and the flat structure,reducing the machine center of gravity, small size,the overall base and the shell is welded form, bearing strength.

Configuration of liquid rubber damping shock absorber damping fluid or, more effectively eliminate the vibration can be realized without basic installation.

Shell can flip clamshell model with a large or small, flip cover with feed tube can be wquipment, washing pipe, observation port, light mouth and spray systems, other protective devices can be equipped with nitrogen to ensure the centrifuge separation chamber and outside air Direct type-specific motor, belt drive eliminates the potential dust, inverter start, start the smooth, dynamic braking, the whole good sealing performance, can be anti-explosion, can be applied to toxic and flammable, explosive sitution. Nitrogen also can be equipped with protective devices to ensure the centrifuge chamber and the outside air iso lation.

Working principle:

PSC slab based on the discharge centrifuge drum parts, Directmotor driven drum rotates at high speed itself, forming a centrifugal force field, no pass-falling high-speed centrifuge, high soeed and large separation factor. Equipped with a closed upper lid and write catheters, feeding tubes feeding from the top center of gravity into the center of the fabric devices, liquid by the fabric is uniformly deposited on the drum wall devices,high-speed centrifuge spin, the role of the centrifugal force field with solid material deposited on the drum inside the liquid by siphon write-liquid discharge device, the solid phase to be shut down manually after unloading from the top.

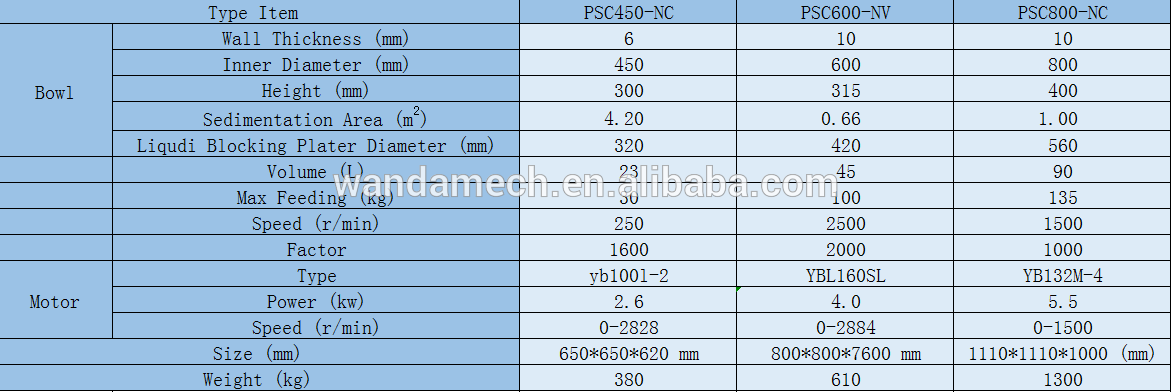

Product technical parameter:

Deatiled Pictures:

1.We will provide one-year warrantee to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.

2. Consultant services for whole machine life, 24 hours technical support by email and telephone.

3.Send technicians to the jobsite for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

LIAOYANG WANDA MACHINERY CO.,LTD is specialized in design, development, manufacture and sale of pharmaceutical, chemical and packaging machinery.Our products include filter, centrifuge, mixer, tablet press machine, granulator, dryer, packing machine, teabag packing machine, etc. Looking to the future with a commitment to design innovation and quality products, supported by an outstanding level of customer service. The unexcelled quality medical machinery can be easily obtained from us because we maintain the quality and standard of our products from incoming raw materials to the finished products. Our company follows strict quality controls and various systematic procedures. We take utmost care of quality at every stage of the manufacturing process. Our research and development wing is our asset that develops and incorporates innovative ideas and products. Our Team is full of experienced and qualified professionals, who have sound knowledge about the quality of our medical machinery. Our products are far sold to Europe, U.S.A., and the southeast Asia. They are well received by customers both at home and abroad.

Other featrue pruducts:

Contact us:

China

China