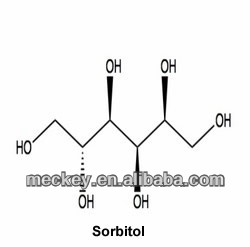

Sorbitol Production Line,

Sorbitol From Crystal glucose!!!

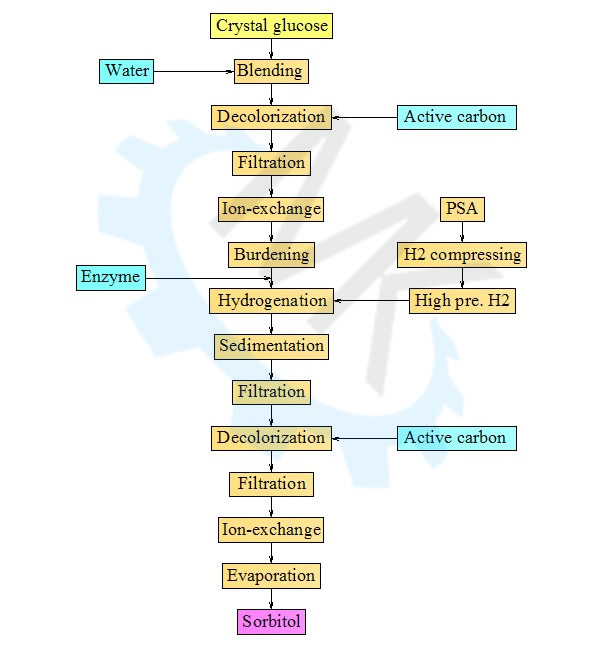

FLOW DIAGRAM

PRODUCT SPE.

Item | Standard | Result |

Character | Crystal, sweetness, viscous liquid | Qualified |

DS/% | 69.0-71.0 | 70.2 |

Mass fraction/% | ≥70.0 | 78.6 |

PH | 5.0-7.5 | 6.0 |

Relative density | 1.285-1.315 | 1.297 |

Reducing sugar (glucose)/% | ≤0.21 | 0.17 |

Total sugar (glucose)/% | ≤8.0 | 7.25 |

Residue/% | ≤0.10 | 0.03 |

Heavy metal (Pb)/% | ≤0.0005 | <0.0005 |

Pb/% | ≤0.0001 | <0.0001 |

As/% | ≤0.0002 | <0.0002 |

Chloride (Cl)/% | ≤0.001 | <0.001 |

Sulphate (SO2)/% | ≤0.005 | <0.005 |

Ni/% | ≤0.0002 | <0.0002 |

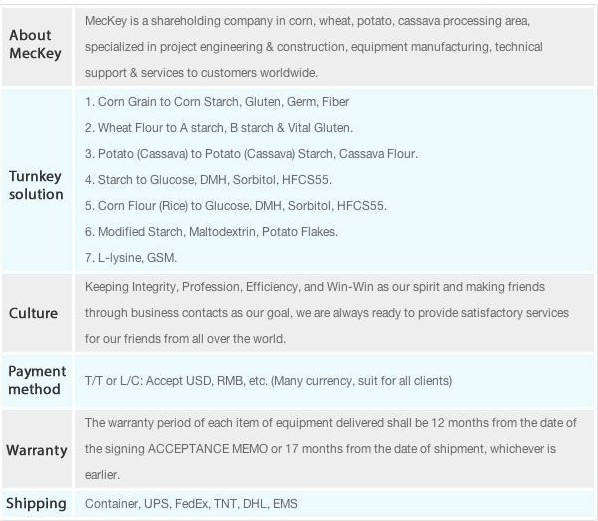

DESCRIPTION

General process description:

(1) Glucose syrup adjustment: Glucose syrup coming from crystal glucose plant is adjusted to the qualified DS with water.

(2) Decoloring and filtration: The qualified glucose syrup is sent to the decoloring tank for decoloring with active carbon input. After that the AC will be removed by the filter, and the syrup will be sent to the next section.

(3) Ion exchange: Tiny foreign items and bad odor is removed via ion exchanger. Then, the material will be qualified to the hydrogenation section.

(4) Hydrogenation: After burdening, the qualified material is sent to the reactor with aid of high pre. H2. By the reaction, the material will be turned to the crude sorbitol. Then the material is sent to the flash tank for cooling. And then it will be sent to the sedimentation tank.

(5) Sedimentation and filtration: After sedimentation tank, the accelerant is separated from the crude sorbitol, then recycled and reuse. The material is sent to the next section after filtration.

(6) Decoloring and filtration: The crude alcohol is sent to the decoloring tank for decoloring with active carbon input. After that the AC will be removed by the filter, and the syrup will be sent to the next section.

(7) Ion exchange: Tiny foreign items and bad odor is removed via ion exchanger. By this way, the material will be turned to be qualified.

(8) Evaporation: The qualified sorbitol is totally cleaned through safety filter, then it is sent to evaporator for concentrating to reach the required DS as final product.

1. Q: If I want to know the price, what info should I provide?

A: You should inform us some basic info , such as: raw material, final product, input capacity or output capacity, specifiction of material and product, etc.

2. Q: If I already have a production line, can I add some machines to increase the capacity?

A: That's viable, pls contact us and we can help you find a suitable solution.

3. Q: How about the automatic level?

A: Depens on you, we have manual/ semi-automatic/ full-automatic control.

4. Q: How about the installation and commissioning?

A: We can send our engineers abroad for the supervision.

5. Q: What's the capacity you can supply of the project?

A: 5000tons per year to Max.

6. Q:What's the brand of your equipments?

A: Most of them are made in China with high-quality.

7. Q: Which kind of sorbitol can I produce by your equipments?

A: VC grade sorbitol and daily used sorbitol.

Sea Worthy Package and according to the customer's requirement.

3-4 months after getting the downpayment.

1) Implementations of automation systems, computer 2D/3D modeling and advanced

CAD/CAM technology.

2) Turn-key plants for the production of wheat starch, corn starch, potato starch and

starch derivatives such as glucose, fructose, crystallized glucose, sorbitol,

etc.

3) Professional engineers with ample on-the-job training experience.

4) A team working at site for the guidance of installing, commission works.

5) Low water and low energy consumption design to save your money.

6) Equipments are made of stainless steel, one year warranty, life-long maintenance.

C-Credit: We promise only what we can do to do our customers and keep our promise.

E-Efficient: Our work is efficient based on our qualified staff and company’s standard working

process.

E-Exact: We study your requirements and supply exact solutions to you.

S-Standard: We have standard systems to guarantee our activities to be complied with

international ones.

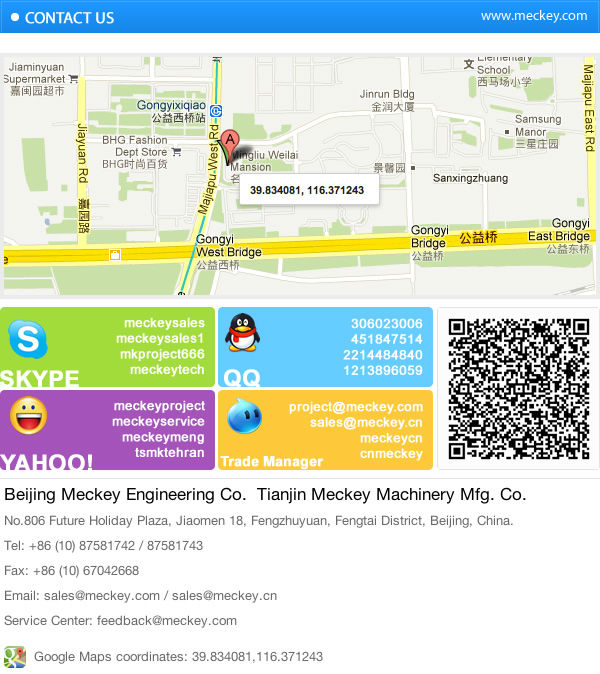

WE ARE WHERE YOU ARE

By choosing MecKey you are choosing the perfect long-term parter for your daily operation. Our

service network can reach you wherever you are.

China

China