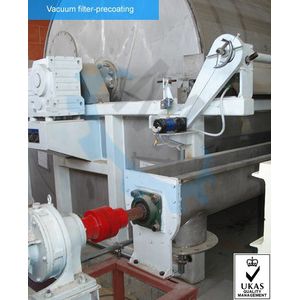

Vacuum Rotary Drum Filter,

Rotary Drum Filter Press for corn starch !!!

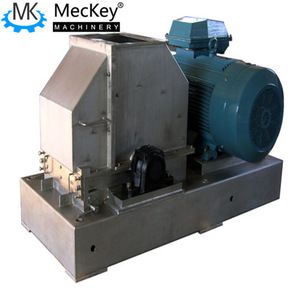

MKPF pre-coating rotary-drum filter is developed and manufactured by absorbing European advanced technology. The professional manufacturing technique and advanced design idea make it be widely used in pharmacy industy, foodstuff industry and starch glucose making industry. It is suitable for the process which needs filtration and doesn't need filter residue.

- It is designed based on customers' different requests.

- Structure is advanced and reasonable while appearance is neat and beautiful.

- Processing devices are in series while installation is simple.

- Due to applying advanced pre-coating technology, filtrate is with high clarity, low solid content and can be easily re-used.

- It employs automatic peeler discharge, which is of high efficiency.

At first, on the surface of drum, a layer of pre-coat of filter aid like bergmeal or perlite should be formed evenly. Processing material is filtered into the bottom basin of the equipment. Under the function of vacuum, filter liquid goes through subsequently the pre-coat layer, filter cloth, imbibing tube, filter liquid collection pipe, and vapor liquid separator then enters into next processing section. Meanwhile the solid powder or other foreign impurities in the material is counterchecked by the pre-coat then removed by movable peeler continuously. When the thickness of the residual pre-coat is less than 10mm, it needs pre-coating again.

| Model | MPKF-10 | MKPF-15 | MKPF-20 | MKPF-25 | MKPF-30 | MKPF-35 | MKPF-40 | MKPF-45 | MKPF-50 | MKPF-60 |

| Filtering area(m2) | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 |

| Capacity (m3/h) | 0.32-0.56 | |||||||||

| Discharge glucose syrup(DS) | 30-35% | |||||||||

| Vacuum (MPa) | 0.04-0.06 | |||||||||

| Power (kw) | 2.2 | 2.2 | 2.2 | 2.2 | 3 | 3 | 3 | 4 | 4 | 4 |

| Length (mm) | 3862 | 3850 | 4750 | 5135 | 5780 | 5430 | 5966 | 6500 | 7020 | 7510 |

| Width (mm) | 3150 | 4000 | 4000 | 4000 | 4000 | 4000 | 5000 | 5000 | 5000 | 5000 |

| Height (mm) | 2087 | 2785 | 2785 | 2785 | 2785 | 2785 | 3680 | 3680 | 3680 | 3680 |

| Weight (kg) | 5200 | 5850 | 6550 | 7130 | 8125 | 9560 | 11050 | 12980 | 14680 | 15780 |

More info pls feel freely to contact with our team!

C-Credit: We promise only what we can do to do our customers and keep our promise.

E-Efficient: Our work is efficient based on our qualified staff and company’s standard working

process.

E-Exact: We study your requirements and supply exact solutions to you.

S-Standard: We have standard systems to guarantee our activities to be complied with

international ones.

WE ARE WHERE YOU ARE

By choosing MecKey you are choosing the perfect long-term parter for your daily operation. Our

service network can reach you wherever you are.

China

China