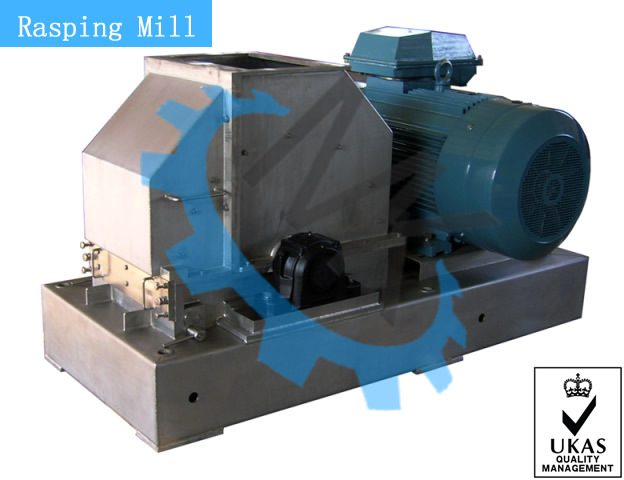

Rasping Mill

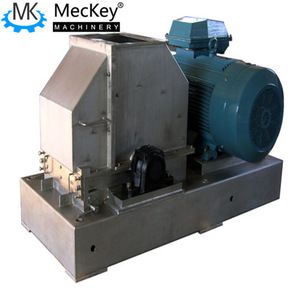

The rasping machine is used to crush the Cassava into slurry and granules.

The rasper is widely used in Cassava starch processing industry for Cassava crushing. Cassava spin into the gap of stator and rotor in which it is crushed into granules and the uniformity starch slurry falls into the basin via the sieve.

The device is made of stainless steel, the rotor is made of special stainless steel by forging process, and rotor is installed on hundreds of specially designed, two-way combination rasps with the thickness of 1.25mm.

MecKey manufactures the equipment for customers wholeheartedly. The distance between the stator and rotor is only 1 ~ 2mm, which ensures higher efficiency of the rasping mill. The simple rasp clamping system ensures rasp works in the best position. And it is very simple to assemble and disassemble the mill, there is no need to use special tools, general staff is OK. The capacity of the entire production line can be adjusted by adjustable speed feeding conveyor.

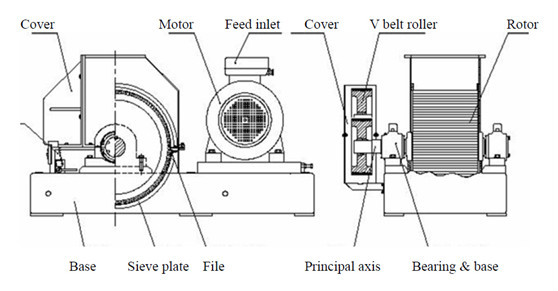

Structure

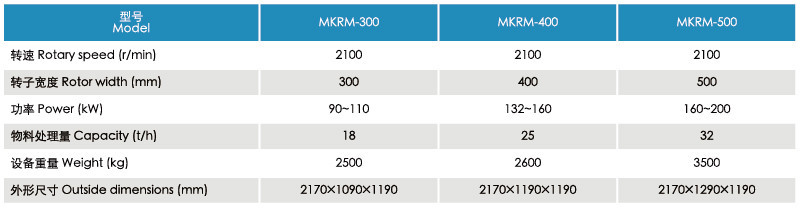

Main Technical Specifications

Characteristics of the equipment

1.The rasping mill is made of stainless steel to prevent starch pollution;

2.The rasping mill surface is treated in a special process, beautiful and oil & dirt resistance;

3.The rasping mill is easy and safe to operate.

Packaging: Seaworthy by container

Delivery: 2-5 months

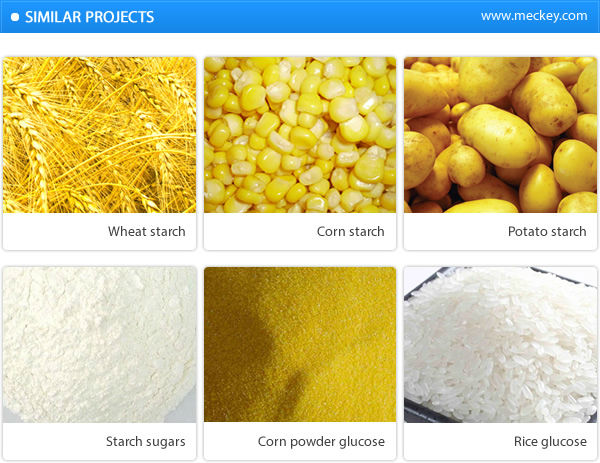

Our production line

1. Advanced and reliable potato processing technology.

2. Energy-saving, water-saving, labor-saving and little pollution. hot recycling close type production and the process water will be recycled .

3.Mostly machinery with fully stainless steel to be sure these is no corrosion.

4. Advanced surface treatment craft. Oil and dirty resisting.

5. Many various capacity option from 0.5 tph to 20 tph.

The best solution project and highest possible quality machines will be offered according to your Demands. Maximum your cost performance.

Our team

1.Strong and vigorous technological force member.

2.Abundant theory and practical experience.

3.The zealous service and fast reply.

4.The scientific management system.

Our team will offer specialized and kindly service for you from end to end.

Our culture

Keeping Integrity, Profession, Efficiency, and Win-Win as our spirit and making friends through business contacts as our goal, we are always ready to provide satisfactory services for our friends from all over the world.

By choosing MecKey you are choosing the perfect long-term partner for your daily operations. Our service network can reach you wherever you are.

About Meckey

Meckey is a shareholding company in corn, wheat, potato, cassava, processing area, secialized in project engineering & construction, equipment manufacturing, technical support & sevices to customers worldwide.

China

China