Maltodextrin Powder Production Line,

Maltodextrin From Starch!!!

PRODUCT CHARACTERISTICS

1) Implementations of automation systems, computer 2D/3D modeling and advanced

CAD/CAM technology.

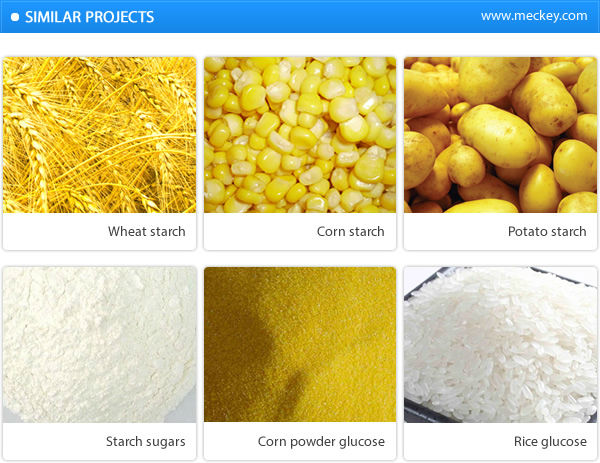

2) Turn-key plants for the production of wheat starch, corn starch, potato starch and

starch derivatives such as glucose, fructose, crystallized glucose, sorbitol,

etc.

3) Professional engineers with ample on-the-job training experience.

4) A team working at site for the guidance of installing, commission works.

5) Low water and low energy consumption design to save your money.

6) Equipments are made of stainless steel, one year warranty, life-long maintenance.

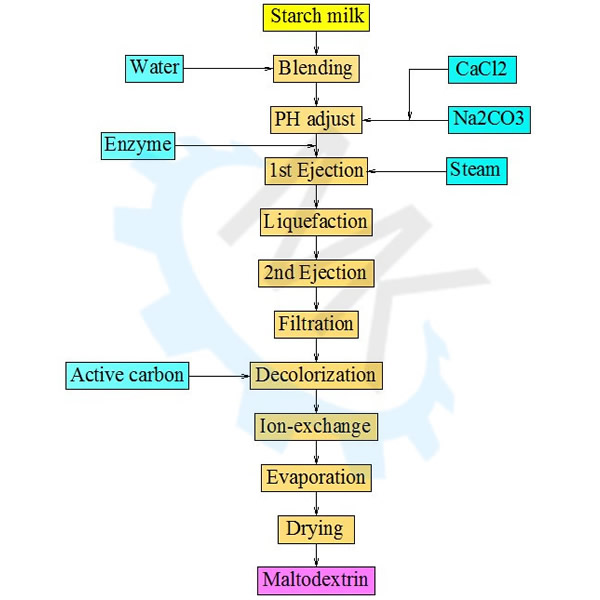

PROCESS FLOW BLACK DIAGRAM

| MD10 | MD15 | MD20 | |

| DE value / % | <11 | 11~16 | 16~20 |

| Moisture / % | ≤ 6.0 | ≤ 6.0 | ≤6.0 |

| Solubility / % | ≥ 98.0 | ≥ 98.0 | ≥ 98.0 |

| PH | 4.5~6.5 | 4.5~6.5 | 4.5~6.5 |

| Ash / % | ≤ 0.6 | ≤ 0.6 | ≤ 0.6 |

COOPERATION WITH CLIENTS

Visiting Factory

Testing Product

Technical Supporting

Construction Site

Turn Key Project

PROCESSING EQUIPMENT DISPLAY

In addition, it can be used as waste-heat evaporator with the resources of waste steam from bundle

This filter press is a kind of intermittent pressure- adding percolation equipment which can be used for almost all kinds of solid-liquid separation. It is widely used in petroleum, chemical engineering, dyestuff, medicine, foodstuff, papermaking, waste water treatment and so on.

It has following advantage:

Advanced structure design considering of machinery, electricity and hydraulic in one machine.

Easy operation, simple maintaining.

All kinds of material of filtering plate are available such as plastic, rubber, enhanced polypropylene, stainless steel and cast iron.

High efficiency, ideal equipment for processing suspension.

.

other foreign impurities in the material is counterchecked by the pre-coat then removed by movable peeler continuously. When the thickness of the residual pre-coat is less than 10mm, it needs pre-coating again.

Functional area of pre-coating rotary vacuum filter can be designed based on customers’ different requests, from 5m2 to 80m2 is available.

COMPANY PHILOSOPHY

C-Credit: We promise only what we can do to do our customers and keep our promise.

E-Efficient: Our work is efficient based on our qualified staff and company’s standard working

process.

E-Exact: We study your requirements and supply exact solutions to you.

S-Standard: We have standard systems to guarantee our activities to be complied with

international ones.

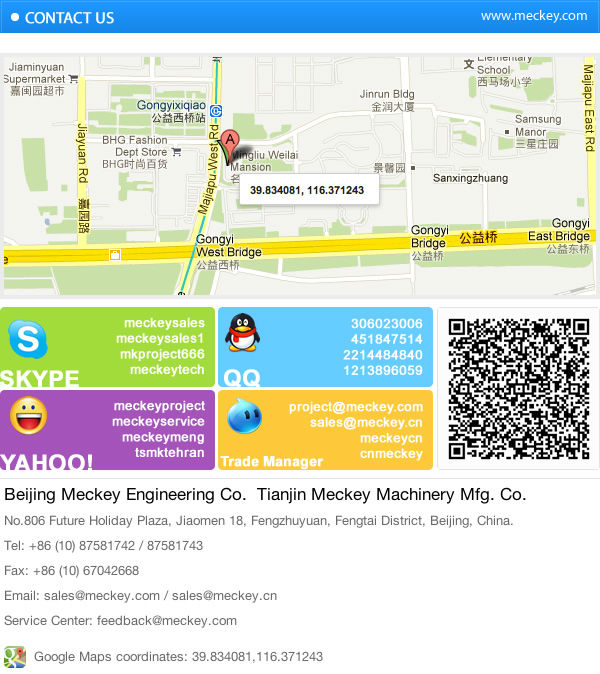

WE ARE WHERE YOU ARE

By choosing MecKey you are choosing the perfect long-term parter for your daily operation. Our

service network can reach you wherever you are.

China

China