Rice glucose processing plant

Rice glucose processing plant

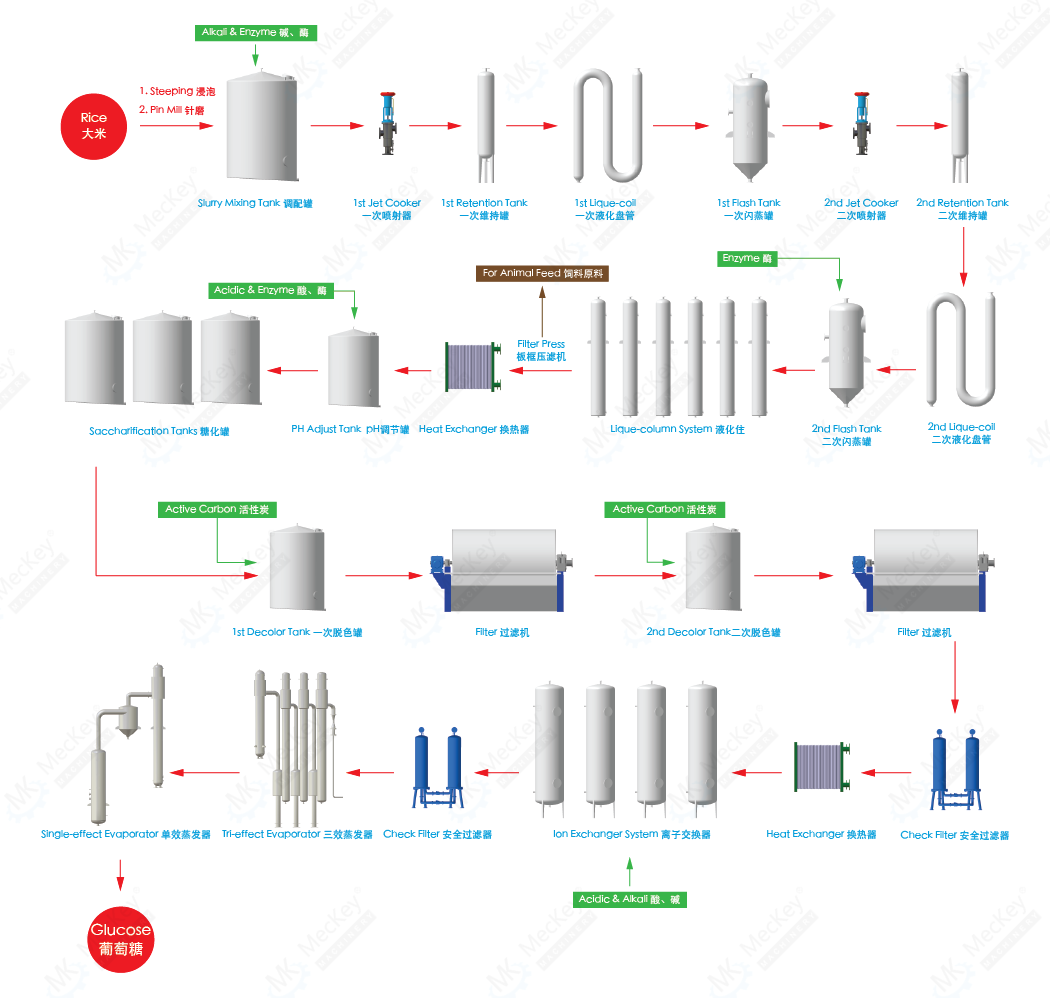

(1) Starch milk adjustment: Unload the broken rice to rice tank, add a certain amount of water, then mixing them and send to steeping tanks for softening. Dipped rice is pumped to crashing stage after de-stone, de-iron and milling, then send it to rice milk storage tanks. The PH and temperature are adjust to a proper value, DS value of rice milk is adjusted to 28-32%,then sent to the next section.

(2) Liquefaction: Starch milk is sent to buffer tank, and add liquefaction enzyme then liquefied by jet cooker. We need twice jets for better reaction. Then the material is sent to flash tank and PH adjusting tank for cooling and PH adjustment.

(3) Rice gluten feed making: The mixed syrup goes to filter press for removing the protein residues, fiber, etc. Then using the process water wash the residue to recover glucose. After washing, the residues are sent to press filter and bundle dryer in turn for gluten feed making.

(4) Saccharification : Sending the adjusted liquefied material to saccharification tanks and add enzyme for reaction. After being kept a certain time reaction, the required DE value of the glucose is produced, then sending to the enzyme killer to kill the enzyme.

(5) Filtration and decolorization: Glucose gets through the filter to remove protein and other impurities, then at the appropriate temperature passes by active carbon to decoloring, finally send to filters to remove activated carbon and send to the next section.

(6) Ion exchanger: Tiny foreign items and bad odor are removed via ion exchangers then we can get the high quality glucose.

(7) Evaporation: The glucose is totally cleaned after get through safety filter machine then sent to evaporator for concentrating a required DS of glucose as final product.

Project photos

China

China