Features:

Its dry speed is very quick. In general, it needs 5-15 seconds. It has feature of momentary dry.

Because raw material can be dried momentarily. Especially, it is suitable for drying thermal sensitive raw materials. It can maintain color, smell and smell of raw materials.

Its operation is stable and simple. Its regulation and control is very convenient. It is easy to realize continuous operation.

The distribution, fluidity and solubility of product are good.

Principle of work:

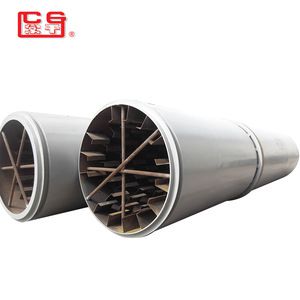

Air is turned into hot air through air filter and heater and enters into hot air distributor at the top of dry chamber and then enters into dry chamber and rotates in the state of helix. At the same time liquid of raw material is sent to centrifugal atomizer at the top of dry chamber pumped by pump through filter, lnwhile liquid of raw material atomizers small drops. Air ad liquid of raw material flow and contact each other fully. The moisture vaporize rapidly. Liquid of raw material is dried into finished product in a short time. The finished product is discharged through cyclone separator at the bottom of drier. The wasted air is exhausted through fan.

| item\type | LPG-5 | LPG-25 | LPG-50 | LPG-100 | LPG-150 | LPG-200 | LPG-500 | LPG-800-1000 |

| max evaporated zmount of moisture kg/h | 5 | 25 | 50 | 100 | 150 | 200 | 500 | 800-1000 |

| spay type | high speed centrifugal atomizer | |||||||

| revolution of atomizer rpm | 25000 | 18000 | 16000 | 11000-13000 | ||||

| diameter of atomizer mm | 50 | 120 | 150 | by craft | ||||

| diameter of tower mm | 0.9 | 1.75 | 2.3 | 2.7 | 3 | 3.2 | 4.7 | |

| power of eletric heating kw | 9 | 31.5 | steam+18 | steam+36 | steam+54 | by craft | ||

| heating source | electric,stream+electric and oil fuel ,gas fuel,hot air furnace | |||||||

| overall dimension (L×W×H)m | 1.6 ×9.1 ×1.75 | 4 ×2.7 ×4.5 | 4.5 ×2.8 ×5.5 | 5.2 ×3.5 ×6.7 | 7 ×5.5 ×7.2 | 7.5 ×6 ×8 | 12.5 ×8 ×10 | basis ground |

China

China