Description

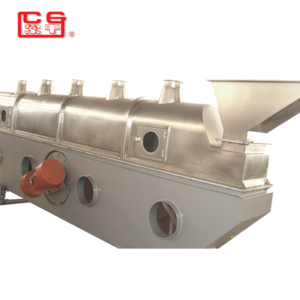

table salt fluid bed drying machine is suitablity in chemical industry, light industry, pharmaceutical, food, plastic, oil, slag, salt, sugar and so on, for drying , cooling and weting.

Features

The vibration is created by motor. Lt is stable in operation and convenient in maintenance, low noise and long life.

High Effection, raw material is heated evenly and heat exchange is fully

used and dry capacity is high. Compared with ordinary drier, the energy can

be saved about 30%.

It is good in regulation and wide in suitablity. The thickness of raw material layer and movable speed inside the machine and the amplitude can be adjusted through continuos variable speed.

It is small for danaging the surface of raw material. The equipment can be

used for drying raw materials that are easy broken. The drying effect can not be affected even if raw materials have anomaly shape.

Technical parameters

| model | area of fluidized-bed m2 | temperature of air in | temperature of air out | capacity to vappor moisture Kg/h Kg/h | vibration motor | |

| model | power | |||||

| ZLG0.30×3 | 0.9 | 70-140 | 40-70 | 2035 | ZDS10-6 | 0.75×2 |

| ZLG0.30×4.5 | 1.35 | 70-140 | 40-70 | 3550 | ZDS10-6 | 0.75×2 |

| ZLG0.45×4.5 | 2.025 | 70-140 | 40-70 | 5070 | ZDS10-6 | 1.1×2 |

| ZLG0.60×4.5 | 2.7 | 70-140 | 40-70 | 7090 | ZDS10-6 | 1.1×2 |

| ZLG0.45×6 | 2.7 | 70-140 | 40-70 | 80100 | ZDS10-6 | 1.1×2 |

| ZLG0.60×6 | 3.6 | 70-140 | 40-70 | 100130 | ZDS25-6 | 1.5×2 |

| ZLG0.75×6 | 4.5 | 70-140 | 40-70 | 120170 | ZDS25-6 | 1.5×2 |

| ZLG0.9×6 | 5.4 | 70-140 | 40-70 | 140170 | ZDS30-6 | 2.2×2 |

| ZLG0.6×7.5 | 4.5 | 70-140 | 40-70 | 130150 | ZDS30-6 | 2.2×2 |

| ZLG0.75×7.5 | 5.625 | 70-140 | 40-70 | 150180 | ZDS40-6 | 3.0×2 |

| ZLG0.9×7.5 | 6.75 | 70-140 | 40-70 | 160210 | ZDS40-6 | 3.0×2 |

| ZLG102×8 | 9.6 | 70-140 | 40-70 | 200280 | ZDS50-6 | 3.7×2 |

| modeldimension | A | B | C | D | E | F | weight(kg) |

| ZLG0.30×3 | 3000 | 300 | 1350 | 900 | 430 | 1650 | 1250 |

| ZLG0.30×4.5 | 4500 | 300 | 1350 | 900 | 430 | 1650 | 1560 |

| ZLG0.45×4.5 | 4500 | 450 | 1550 | 950 | 430 | 1700 | 1670 |

| ZLG0.60×4.5 | 4500 | 600 | 1650 | 950 | 430 | 1700 | 1910 |

| ZLG0.45×6 | 6000 | 450 | 1650 | 950 | 430 | 1700 | 200 |

| ZLG0.60×6 | 6000 | 600 | 1700 | 1000 | 500 | 1700 | 2410 |

| ZLG0.75×6 | 6000 | 750 | 1850 | 1000 | 600 | 1850 | 2340 |

| ZLG0.9×6 | 6000 | 900 | 2000 | 1000 | 600 | 1850 | 3160 |

| ZLG0.6×7.5 | 7500 | 600 | 1850 | 1000 | 600 | 1850 | 3200 |

| ZLG0.75×7.5 | 7500 | 750 | 2000 | 1000 | 600 | 1850 | 3600 |

| ZLG0.9×7.5 | 7500 | 900 | 2100 | 1000 | 600 | 1850 | 4140 |

| ZLG1.2×7.5 | 7500 | 1200 | 2500 | 1150 | 800 | 2050 | 5190 |

Principle of work

Raw materials is fed into the machine from the inlet and moves forward continuously along with the level of fluidized-bed under the action of vibration. The hot air passes through fluidized-bed and carries out hot heat exchange with damp raw material. Then the damp air is exhausted out through cyclone seperator and duster and the dry raw material is discharged through discharge outlet.

China

China