|

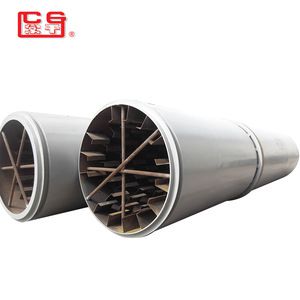

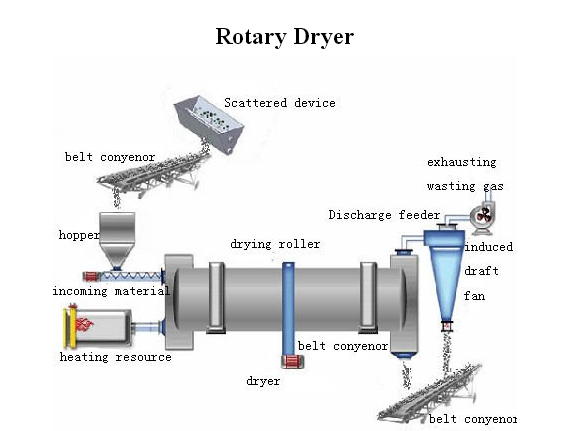

SpecificationsRotary dryer is the choice for high throughput capacity applications involving high moisture,Descriptions Drum drying equipment is a kind of rotating continuous drying equipment with internal heating conducting-style. Certain thickness of materials film attach to the drum from material liquid vessel under the drum. Heat is transferred to the internal wall of the cylinder through pipes and then to the external wall and to materials film, to evaporate the moisture in materials film so as to dry materials. Dried products are then scraped off by the blade fitted on the surface of the cylinder, fall down to the spiral conveyor under the blade, and are conveyed, collected and packed. Features 1.High heat efficiency. The principle of heat transfer of the cylinder dryer is heat conduction and the conducting direction keeps identical in the whole operation circle. Except heat loss of end cover and radiation loss, all heat can be used for evaporation of wet materials on the wall the cylinder. The efficiency can reach 70-80%. |

|

|

rotary drier Technical parameters

| item(m) | priductive capacity(t/h) | revolution(r/min) | motor power(Kw) | install angle(.) | Temp.of final |

| Φ1.0×5.0 | 0.5-1.2 | 0.6-6 | 4 | 3-5 | ≤1.5% |

| Φ1.2×6-10 | 1.5-3 | 0.6-6 | 5.5 | 3-5 | ≤1.5% |

| Φ1.5×12-18 | 3-5.5 | 0.6-6 | 15 | 3-5 | ≤1.5% |

| Φ1.8×12-18 | 5-6.5 | 0.6-6 | 18.5 | 3-5 | ≤1.5% |

| Φ2.2×12-22 | 7-12 | 0.6-6 | 22 | 3-5 | ≤1.5% |

| Φ2.4×15-20 | 9-15 | 0.6-6 | 30 | 3-5 | ≤1.5% |

| Φ3.0×25 | 16 | 0.6-6 | 55 | 3-5 | ≤1.5% |

| model | heat direct and sequence | heat direct and retrograde | compound heating | |||

| type of material | mineral | HP | ammonium sulphate | phosphorus fertilizer | coal | |

| capacity kg/h | 1000 | -66 | 15000 | 20000 | 12000 | 5000 |

| primary moisture % | 30 | 13 | 6 | 1.5 | 5 | 6.5 |

| final moisture % | 15 | 0.3 | 1 | 0.1 | 0.1 | 0.1 |

| average dim. mm | 6.5 | 0.05 | 4.7 | 0.5-0.7 | 0.5 | 5 |

| thickness of material mm | 770 | 800 | 1890 | 1100 | 1500 | 750 |

| capacity of hot air kg/h | 39000 | 5400 | 10750 | 9800 | 6500 | 16000 |

| temp. of air in | 600 | 165 | 500 | 180 | 650 | 570 |

| temp. of material out | 42 | 100 | 70 | 80 | 75 | |

| heating style | gas | steam electric+heating | heavy oil | coal fuel furnace | heavy oil | heavy oil |

| ratio of feed | 6.3 | 7 | 7.5 | 7.8 | 18 | |

| rotation speed rpm | 4 | 4 | 3.5 | 3 | 4 | 2 |

| angel . | 0.04 | 0.005 | 0.03 | 0.05 | 0.05 | 0.043 |

| quatity of oar | 12 | 24 | 12 | 22 | 8 16 | 6 12 |

| dim. of drier m | 2.0 | 1.5 | 2 | 2.3 | 2 0.84 | 24 0.95 |

| length of drier m | 20 | 12 | 17 | 15 | 10 | 16 |

| driving power kw | 22 | 7.5 | 15 | 11 | 11 | 15 |

|

|

China

China