XF Series Boiling Drier

Description

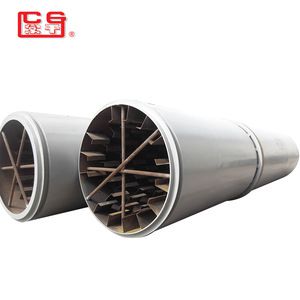

Dryer is also call as fluidize-bed. Lt consists of air filter, heater, fluidized-bed main machine, feeder, cyclone seperator, cloth bag duster, high-pressure centrifuge fan and operation table. Because the properties of raw material exist difference, when equip the dust removing equipment, it should consider the practical need. It can select cyclone seperator and cloth bag duster at the same time or one of them. In genral speaking, it needs to select cyclone seperator only for raw material that is large in specific gravity and cloth bag duster for powder and small granule raw materials that is light in gravity. Meanwhile there is air feeding device and belt conveyor for seletion.

Separated granule solid raw material is fed into fluidized-bed drier through feeder. Fresh air through filtering and heating is sent to the bottlom of fiuidized-bed by fanand contacts with solid raw material on distributing plate. In this way the fluidized state is formed and the heat exchang between air and solid is carried out. The dried raw material is discharged from outlet and wasted gas is exhausted from the top of fluidized-bed where catches solid powder through cyclone separator, cloth bag duster.

Stream, electricity or hot air furnace can can be used(it can be supplied as request)

It is suitable for drying separated granule such as, raw material of pharmaceutical industry, tablet, tablet of drink of Chinese traditional medicines; Plastic resin, citric acid, other powder and granule of chemical industry, powder of dtink, corn embryo feed of foodstuff industry and so on. The Max diameter of raw material to be dried will 6 mm and the best diameter will be 0.5-3mm.

Features

Automatic production can be realized. It is continous drying equipment. Its features are quick in drying speed, Iow in drying tempment, It can guarantee the quality of produtcts and is in conformity with the requirements of GMR

Technical parameters| technicalmodel and specifications | XFO0.25

-1 | XFO0.25

-2 | XFO0.25

-3 | XFO0.25

-6 | XFO0.3

-2 | XFO0.3

-4 | XFO0.3

-6 | XFO0.3

-8 | XFO0.3

-10 | XFO0.4

-4 | XFO0.4

-6 | | area of layer(m2) | 0.25 | 0.5 | 1.0 | 1.5 | 0.6 | 1.2 | 1.8 | 2.4 | 3.0 | 1.6 | 2.4 | | drying capacity (kg h2o/h) | 1015 | 2025 | 3045 | 5275 | 30 | 4260 | 6390 | 84120 | 105150 | 5680 | 84120 | | power of fan (kw) | 5.5 | 7.5 | 15 | 22 | 7.5 | 18.5 | 30 | 37 | 48 | 30 | 37 | | temperature of air in () | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | | temperature of air in () | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | | overall dimensions(main machine)L×W×H | 1

×0.6

×3.35 | 2

×0.6

×3.35 | 4

×0.6

×3.35 | 6

×0.6

×3.35 | 2

×0.7

×3.4 | 4

×0.7

×3.4 | 6

×0.7

×3.4 | 8

×0.7

×3.4 | 10

×0.7

×3.4 | 4

×1

×3.58 | 6

×1

×3.58 | | occupied area (m2) | 18 | 25 | 35 | 40 | 25 | 38 | 45 | 56 | 70 | 18 | 56 |

|

Technical parameters | technicalmodel and specifications | XFO0.25

-1 | XFO0.25

-2 | XFO0.25

-3 | XFO0.25

-6 | XFO0.3

-2 | XFO0.3

-4 | XFO0.3

-6 | XFO0.3

-8 | XFO0.3

-10 | XFO0.4

-4 | XFO0.4

-6 | | area of layer(m2) | 0.25 | 0.5 | 1.0 | 1.5 | 0.6 | 1.2 | 1.8 | 2.4 | 3.0 | 1.6 | 2.4 | | drying capacity (kg h2o/h) | 1015 | 2025 | 3045 | 5275 | 30 | 4260 | 6390 | 84120 | 105150 | 5680 | 84120 | | power of fan (kw) | 5.5 | 7.5 | 15 | 22 | 7.5 | 18.5 | 30 | 37 | 48 | 30 | 37 | | temperature of air in () | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | | temperature of air in () | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | | overall dimensions(main machine)L×W×H | 1

×0.6

×3.35 | 2

×0.6

×3.35 | 4

×0.6

×3.35 | 6

×0.6

×3.35 | 2

×0.7

×3.4 | 4

×0.7

×3.4 | 6

×0.7

×3.4 | 8

×0.7

×3.4 | 10

×0.7

×3.4 | 4

×1

×3.58 | 6

×1

×3.58 | | occupied area (m2) | 18 | 25 | 35 | 40 | 25 | 38 | 45 | 56 | 70 | 18 | 56 |

|

Technical parameters | technicalmodel and specifications | XFO0.25

-1 | XFO0.25

-2 | XFO0.25

-3 | XFO0.25

-6 | XFO0.3

-2 | XFO0.3

-4 | XFO0.3

-6 | XFO0.3

-8 | XFO0.3

-10 | XFO0.4

-4 | XFO0.4

-6 | | area of layer(m2) | 0.25 | 0.5 | 1.0 | 1.5 | 0.6 | 1.2 | 1.8 | 2.4 | 3.0 | 1.6 | 2.4 | | drying capacity (kg h2o/h) | 1015 | 2025 | 3045 | 5275 | 30 | 4260 | 6390 | 84120 | 105150 | 5680 | 84120 | | power of fan (kw) | 5.5 | 7.5 | 15 | 22 | 7.5 | 18.5 | 30 | 37 | 48 | 30 | 37 | | temperature of air in () | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | | temperature of air in () | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | | overall dimensions(main machine)L×W×H | 1

×0.6

×3.35 | 2

×0.6

×3.35 | 4

×0.6

×3.35 | 6

×0.6

×3.35 | 2

×0.7

×3.4 | 4

×0.7

×3.4 | 6

×0.7

×3.4 | 8

×0.7

×3.4 | 10

×0.7

×3.4 | 4

×1

×3.58 | 6

×1

×3.58 | | occupied area (m2) | 18 | 25 | 35 | 40 | 25 | 38 | 45 | 56 | 70 | 18 | 56 |

|

Technical parameters | technicalmodel and specifications | XFO0.25

-1 | XFO0.25

-2 | XFO0.25

-3 | XFO0.25

-6 | XFO0.3

-2 | XFO0.3

-4 | XFO0.3

-6 | XFO0.3

-8 | XFO0.3

-10 | XFO0.4

-4 | XFO0.4

-6 | | area of layer(m2) | 0.25 | 0.5 | 1.0 | 1.5 | 0.6 | 1.2 | 1.8 | 2.4 | 3.0 | 1.6 | 2.4 | | drying capacity (kg h2o/h) | 1015 | 2025 | 3045 | 5275 | 30 | 4260 | 6390 | 84120 | 105150 | 5680 | 84120 | | power of fan (kw) | 5.5 | 7.5 | 15 | 22 | 7.5 | 18.5 | 30 | 37 | 48 | 30 | 37 | | temperature of air in () | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | 120140 | | temperature of air in () | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | 4060 | | overall dimensions(main machine)L×W×H | 1

×0.6

×3.35 | 2

×0.6

×3.35 | 4

×0.6

×3.35 | 6

×0.6

×3.35 | 2

×0.7

×3.4 | 4

×0.7

×3.4 | 6

×0.7

×3.4 | 8

×0.7

×3.4 | 10

×0.7

×3.4 | 4

×1

×3.58 | 6

×1

×3.58 | | occupied area (m2) | 18 | 25 | 35 | 40 | 25 | 38 | 45 | 56 | 70 | 18 | 56 |

|

China

China