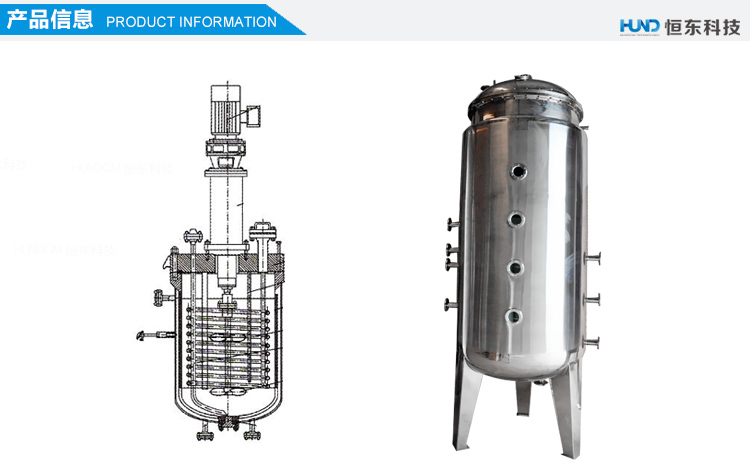

Application:

This device is suitable for traditional Chinese medicine,western medicine,starch sugar,dairy and other food and industrial materials concentrated organic solvents (such as alcohol)recovery for samll-volume,low-temperature heat-sensitive materials varieties vacuum concentration.

Technical Parameters&Use:

| Model | HD-500 | HD-1000 | HD-1500 | HD-2000 |

| Evaporation(kg/h) | 500 | 1000 | 1500 | 2000 |

| Steam Pressure(Mpa) | ≥0.09 | ≥0.09 | ≥0.09 | ≥0.09 |

| Vacuum Degree(Mpa) | 0.08 | 0.08 | 0.08 | 0.08 |

| Concentratration ratio | 1.2-1.3 | 1.2-1.3 | 1.2-1.3 | 1.2-1.3 |

| Dimensions(L*W*H) | 2000X1000X3000 | 2200X1200X3300 | 2500X1300X3500 | 4600X2350X5100 |

1.Alcohol Recovery:Recycling capacity,concentrated by vacuum processes.Improve productivity than the old typr of similar equipment 5-10times,reducing energy consumption by30%,with a small investment the recovery efficiency is high.

2.Concentrate feeding:This equipment uses natural circulation with external heating vacuum evaporation conbination,evaporation speed of up to 1.3specific gravity concentrate;fluid material in the sealed state no foam concentrate,concentrate the drug out of the use of this equipment fluid with no pollution drug sauvignon features and easy to clean (the upper and lower cover to turn on the heater for cleaning).The equipment is simple ,small footprint.Heaters,stainless steel evaporator insulation structure ,moisturzing layer of stainless steel sheet production casing external surface do mirror or matte processing.

About HUNDOM

HUNDOM,found in2003,We own a team with rich experience in the field.

Offer household chemical machinery,food machinery,pharmaceutical machinery,packaging equipment manufactures.

To pay more attention to the details is the core why the products of Hundom enter[rise can keep ahead.HUNDOM Enterprise have developed,self-contained and modernzed products equipment,Which have a closely combination between qualiy of products and appearance of poducts,and make satisfactory meet modernized industrial.We can provide the products and serve you required.HUNDOM Enterprise gain ISO901 international quality system,have 5S management system.To gain inner and international quality guarantee is concert embodiment of "Quality is enterprise's life" in HUNDOM enterprise.

FAQ:

Q1:Can you print our brand on tank?

Yes.Customized brand can be print on the tank according to your requirments.

Q2:Is that factory price?

Yes.We assure you all prices are based on factory.

Q3:How long is the warranty period?

Motor one year.During the warranty period,we shall repair or replace the damaged part accordingly because of any damage due to quality problem.

Q4:Has your tank product been certified?

Yer.Our mixing tank motor passed the engineering tests.

Q5:Why choose HUNDOM?

1.Superior Quality &Reasonable price;

2.Professional project design team&complete project management system;

3.Wide selection for materials and products;

4.Large production capacity;

5.Experienced project installation team & satisfactory after-sales service.

Guangzhou Hundom Machinery Technology Co.,Ltd.

Add:No. 115, No. 7, Haina Industrial Park, Shibi Street, Panyu District, Guangzhou City, Guangdong Province, China

Sales:Lovely Shum

Tel:+86-020-89081205

Mobile +86-138-2213-4643

Welcome to visit our factory !

China

China