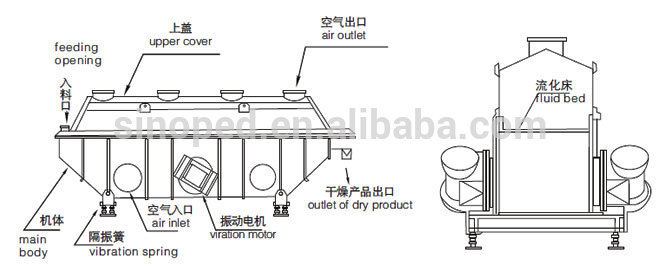

Vibrating malic acid fluid bed dryer is widely used for drying, cooling and damp increasing (or carry out at the same time) for powder or granule materials. Material is fed into the machine from feeding inlet, and moves forward continuously along with the level of fluid bed under the action of vibration force. Hot air passes through fluid bed and carries out heat exchanging with damp material. Then the damp air is exhausted out by exhaust fan, some fine powder is collected by cyclone separator and dust remover, and dried product is discharged from discharging outlet.

Quinoa products-----Malic acid

WHY YOU CHOOSE IT ?

1. Adopts new type quick-open structure for upper bed and bottom bed. Upper bed can be moved easily. So it is very convenient to clean and wash the drying system.

2. Bed plate adopts laser punching, it can avoid the deformation in common punching process effectively.

3. Bottom bed adopts stainless steel seamless tube for supporting, the structure of bed is more stronger and make the life of equipment longer.

4. Material is heated uniformly, heat exchanging is full and drying intensity is high. Energy can be saved about 30%.

5. Vibration source is vibrating motor. It features constant operation, convenient maintenance, low noise and long life.

6. Fluid state is stable, there is no phenomenon of gap or blowing out.

malic acid dryer

7. There is less damage to the surface of material. It can be used for drying material that is easy to broken. The work efficiency is not affected even if the granule of material is irregular.

8. Adopts full sealed structure. It effectively avoids cross infection between and air, the operation environment is clean

WHAT IS VIBRATING LINEAR FLUID BED DRYER USED FOR ?

1. Chemical medicine: a variety of pressed particles, boric acid, borax, hydroquinone,

Malic acid, maleic acid and so on.

2. food materials: liquor tank, monosodium glutamate, sugar, salt, slag,

Watercress, seeds and so on.

3. materials can also be used for cooling, humidification, etc.

Main Technical Parameters

Model | Fluid bed(M2) | Inlet air temperature(°C) | Outlet air temperature (°C) | Evaporate capacity | Vibration motor | |

Model | Power (kw) | |||||

ZLG3×0.30 | 0.9 | 70-140 | 40-70 | 20-35 | ZDS31-6 | 0.8×2 |

ZLG4.5×0.30 | 1.35 | 70-140 | 40-70 | 35-50 | ZDS31-6 | 0.8×2 |

ZLG4.5×0.45 | 2.025 | 70-140 | 40-70 | 50-70 | ZDS32-6 | 1.1×2 |

ZLG4.5×0.60 | 2.7 | 70-140 | 40-70 | 70-90 | ZDS32-6 | 1.1×2 |

ZLG6×0.45 | 2.7 | 70-140 | 40-70 | 80-100 | ZDS41-6 | 1.5×2 |

ZLG6×0.60 | 3.6 | 70-140 | 40-70 | 100-130 | ZDS41-6 | 1.5×2 |

ZLG6×0.75 | 4.5 | 70-140 | 40-70 | 120-140 | ZDS42-6 | 2.2×2 |

ZLG6×0.9 | 5.4 | 70-140 | 40-70 | 140-170 | ZDS42-6 | 2.2×2 |

ZLG7.5×0.6 | 4.5 | 70-140 | 40-70 | 130-150 | ZDS42-6 | 2.2×2 |

ZLG7.5×0.75 | 5.625 | 70-140 | 40-70 | 150-180 | ZDS51-6 | 3.0×2 |

ZLG7.5×0.9 | 6.75 | 70-140 | 40-70 | 160-210 | ZDS51-6 | 3.0×2 |

|

|

Export Documents

After-sale Service

ONE-YEAR warranty period for whole machine except of tubes and human factors etc, 18 months from the date when you received machine or 12 months when installation finished;

Consultant services for whole machine life, 24 hours technical support by email;

Call us by 86-419-2145577/86-419-18341959194 during working time;

UPS-friendly English Soft-ware, user manual and detailed video.

Project in Austrilia

Sino Pharmaceutical Equipment Development (Liaoyang) Co., Ltd. (SINOPED) is a professional manufacturer and supplier of pharmaceutical and chemical machinery and equipment in China. We belong to SINOPEC International Group.

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers, we have designed and developed many types of machinery and equipment in many varieties. Our main products are glass-lined reactors, fermentors, centrifuges, granulators, mixers, dryers, pulverizers, tablet presses, soft and hard blister packing machines, capsule filling machines, cartoners and rollers.

In the past years, we have made great achievements due to our good credit and service. We have established long-term business relations with many customers and some of our overseas customers have appointed us to be their purchase agency in China. Our products are exported to many countries & areas, such as Korea, India, Indonesia, Pakistan, Thailand, Vietnam, Iran, Japan, Denmark, Romania, Bulgaria, Russia, South Africa, Nigeria, the USA, Australia, Canada, Argentina and Chile. Besides machinery and equipment, we also supply production lines, turn key projects and know-how.

In SINOPED you can get your desired goods with the best prices and good quality. We welcome your enquiries from at home and abroad.

WORKSHOP

FAQ

China

China