1.Food Industry: whole milk powder, cocoa milk powder, milk substitute, egg white (yolk), etc. armpit prion, Oats, chicken juice, instant tea, seasoning meat, protein, soybean, peanut protein, protein hydrolyzate, etc. Corn syrup, corn starch, glucose, pectin, maltose, potassium sorbate, pumpkin powder, etc.

2.Pharmaceutical products: Chinese traditional medicine extract (herb extract), medicine colloid, yeast, vitamins, antibiotics, amylase, lipase, etc.

3.Plastics resin: AB, ABS emulsion, urea-formaldehyde resin, phenolic resin, dense plastic (urea) formaldehyde resin, polyethylene, polyvinyl chloride, etc.

4.Detergent: advanced washing powder, normal washing powder, soap powder, soda powder, emulsifiers, brighteners, phosphoric acid agents.

5.Chemical Industry: Sodium fluoride (potassium), alkaline dyestuff and pigment, dye intermediates, Mn3O4, formic silica acid, catalyst, sulfuric acid agent, amino acids, silica, etc..

6.Ceramic: aluminum oxide, ceramic tile material, magnesium oxide, talc, etc.

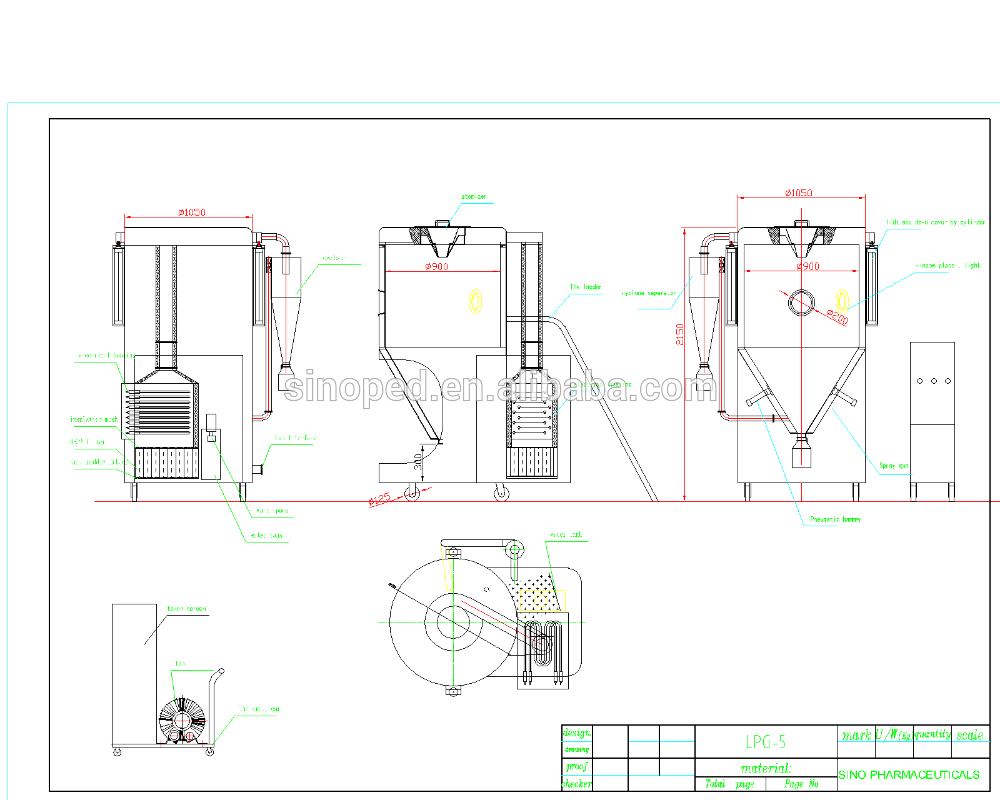

Original liquid would be feed by Peristaltic Pump from vessel, and become spray under High Speed Atomizer, the atomizer would be driven by Compressed Air, Atomizing Disc diameter can reach 25000rpm at most. Peristaltic Pump Flow can be adjusted and stable, which can ensure FEEDING STABLY and CONTROL TEMPERATURE EFFECTIVELY.

The new air would be filtered according to Pre-filter and Mid-filter, then start to heat by ELECTRICITY, until inlet air temp. reach 300~350C(depend on actual need). After this, the heated air would be enter the Spray Chamber uniformly, with the help of Spiral-type Hot-air Distributor on the cover. After hot air touch with Spray(materials), water can be evaporated very fast, fine and dry powder can be collected by Cyclone Separator. All adopt SS304.

| Specification | LPG-5 | LPG-50 | LPG-100 | LPG-300 | LPG-500 | LPG-750 | LPG-1000 | LPG-2000 |

| Air Inlet temperature | 140-550 °C (depend on the product to be dried, and URS) | |||||||

| Air exhaust temperature | 60-120 °C (depend on the product to be dried, and URS) | |||||||

| Nominal water evaporation capacity | 5 Kg / h | 50 Kg / h | 100 Kg / h | 300 Kg / h | 500 Kg / h | 750 Kg / h | 1000 Kg / h | 2000 Kg / h |

| Heating method | High-pressure steam, or steam + electricity, or any kinds of fuel (diesel, natural gas, liquefied petroleum gas or coal, etc.), or solid fuel (any combustible material). Please specify. | |||||||

| Drying tower diameter | 1100 (mm) | 2150 (mm) | 2560 (mm) | 3600 (mm) | 4300 (mm) | 5000 (mm) | 6000 (mm) | 7600 (mm) |

| Dimensions | Design as per configuration of the plant and URS | |||||||

| Product yield | 95-99.9%,depend on the properties of the product and configurations |

Sino Pharmaceutical Equipment Development (Liaoyang) Co., Ltd. follow as SINOPED is a professional manufacturer and supplier of pharmaceutical and chemical machinery and equipment in China, it belong to SINOPEC International Group. We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in the pharmaceutical machinery and equipment field and numbers of professional engineers, we have designed and developed many types of machinery and equipment in many varieties. Our main products are glass-lined reactors, fermentors, centrifuges, granulators, mixers, dryers, pulverizers, tablet presses, soft and hard blister packing machines, capsule filling machines, cartoners and rollers.

China

China