Horizontal Fluid Bed Dryer Suger Dryer Granule Dryer

Scope of application

The machine is suitable for drying, cooling, humidifying of powder and granule materials in chemistry, pharmaceutical, foodstuff, beverage and mining industries, also can be used for drying, cooling and humidifying simultaneously.

1.Pharmaceutical and chemical industries: All kinds of press tablet and granules, boric acid, borax, dihydroxy benzene, malice acid, malefic acid and so on.

2. Foodstuff industry: Distiller’s grains, monosodium, edible salt, mine residue, bean seed, mushroom essence, chicken essence, desiccated coconut and so on.

3. It can also used for raw materials to add up damp or cooling so on.

Raw material feature:

1: material particles are too big or irregular need to fluid.

2: lower speed fluidization is needed to keep particles complete,

3: materials are sticky or sensitive to temperature.

Principle

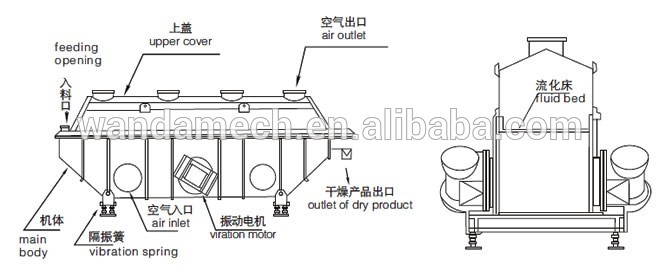

Raw material is fed into the fliud bed dryer from the inlet and moves forward continuously along with the level of fluidized-bed under the action of vibration.The hot air passes through fluidized-bed and carries out heat exchange with damp raw material.Then the damp qir is exhausted out through cyclone separator and duster the dry raw material is discharged through discharge outlet.

Features

1.Raw material is heated evently and heat exchange is fully used and dry capacity is high. Compared with ordinary drier, the energy can be saved about 30%.

2.The vibration is created by motor. It is stable in operation and convenient in maintenance, low noise and long life.

3.The fluided state is stable and no dead angle and phenomenon of broken out;

4.It is good in regulation and wide in suitability. The thickness of raw material layer and movable speed inside the machine and the total amplitude can be adjusted through continuous variable speed.

5.It is small for damaging the surface of raw material. The equipment can be used for drying raw materials that are easy broken. The drying effect can not be affected even if raw materials have anomaly shape.

6. Adopts full sealed structure.It is effective to prevent from cross pollution between raw material and air because the equipment adapts fully closed structure. The environment of operation is clean.

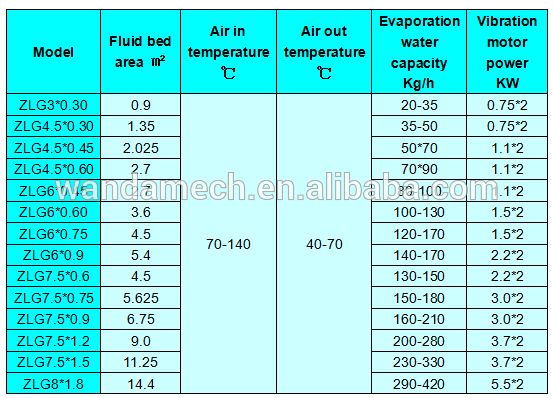

Product technical parameter

Customer Visiting

Product drawing

LIAOYANG WANDA MACHINERY CO.,LTD is specialized in design, development, manufacture and sale of pharmaceutical, chemical and packaging machinery.Our products include filter, centrifuge, mixer, tablet press machine, granulator, dryer, packing machine, teabag packing machine, etc. Looking to the future with a commitment to design innovation and quality products, supported by an outstanding level of customer service.

The unexcelled quality medical machinery can be easily obtained from us because we maintain the quality and standard of our products from incoming raw materials to the finished products. Our company follows strict quality controls and various systematic procedures. We take utmost care of quality at every stage of the manufacturing process.

Our research and development wing is our asset that develops and incorporates innovative ideas and products. Our Team is full of experienced and qualified professionals, who have sound knowledge about the quality of our medical machinery. Our products are far sold to Europe, U.S.A., and the southeast Asia. They are well received by customers both at home and abroad.

Other feature products

Contact us

China

China