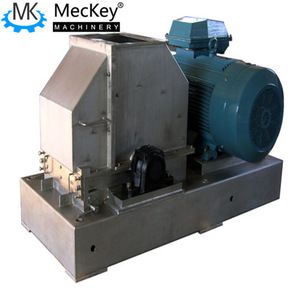

MKCS-500 Centrifuge sieve for cassava starch plant.

Application

Wheat/cassava/potato/sweet potato starch fiber separation centrifugal sieve.

Description

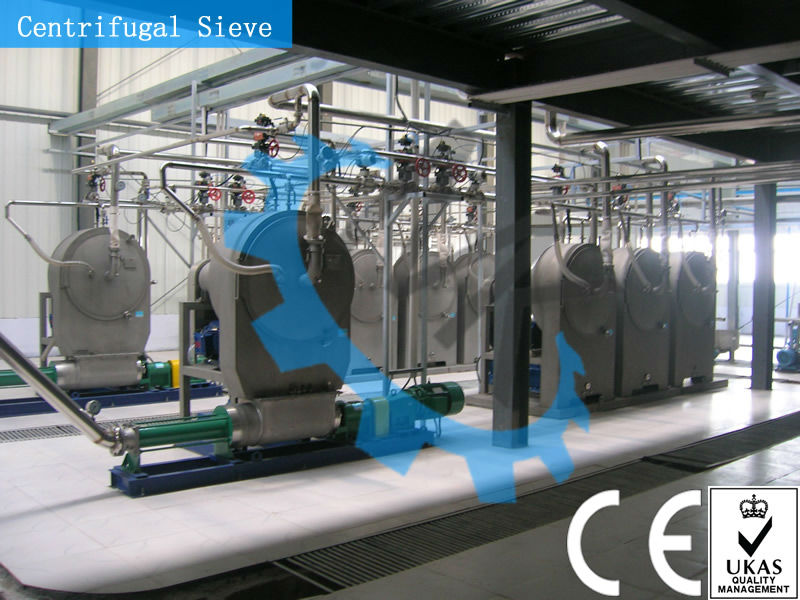

The centrifugal sieve is used to separate fiber (residue) in the cassava starch emulsion. It is widely used for cassava starch extraction in large and medium - sized starch production enterprises.

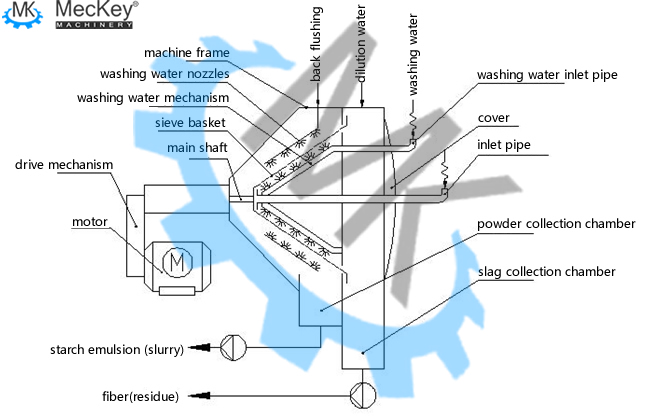

When the equipment running, the starch slurry enters the bottom of the sieve basket, and then under the effect of centrifugal force and gravity, the slurry goes a complex curve movement toward the bigger size direction, even rolling. In the process, the bigger impurities arrive the outer edge of the sieve basket, collecting in the slag collection chamber, whist the starch particle which size is smaller than the mesh fall into the starch powder collection chamber.

The machine has spray nozzle device both in the back and front of the sieve basket. By spraying washing water, the material move speed is accelerated whist the starch particles are easy to separate from the fiber slag.

Characteristics of the equipment

1. The equipment is made of stainless steel to prevent starch pollution;

2. The equipment surface is treated in a special process, beautiful and oil & dirt resistance;

3. The rotating sieve basket is corrected by the authority balancing accuracy to ensure that the equipment running smoothly;

4. Its mesh is manufactured by special plate, beautiful and durable;

5. The nozzle passes strict contrast test of pressure and flow;

6. The devices features big capacity, reasonable allocation of power, high starch extraction rate, easily installed.

Technical Specification

Model | MKCS500 | MKCS650 | MKCS850 | MKCS1000 |

Rotary speed r/min | 900~1100 | 900~1100 | 900~1100 | 900~1100 |

Screen basket diameter mm | 500 | 650 | 850 | 1000 |

Power kw | 11 | 15 | 18.5~37 | 45 |

Capacity(raw potato) t/h | 10 | 20 | 35 | >35 |

Material | SS304 | SS304 | SS304 | SS304 |

Weight kg | 1150 | 1300 | 1480 | 1800 |

Outside dimensions mm | 2300×850×1760 | 1785×1000×1905 | 1965×1200×2055 | 2075×1400×2205 |

Structure chart and equipment photos

Our team

1.Strong and vigorous technological force member.

2.Abundant theory and practical experience.

3.The zealous service and fast reply.

4.The scientific management system.

Our team will offer specialized and kindly service for you from end to end.

Our culture

Keeping Integrity, Profession, Efficiency, and Win-Win as our spirit and making friends through business contacts as our goal, we are always ready to provide satisfactory services for our friends from all over the world.

WE ARE WHERE YOU ARE!

By choosing MecKey you are choosing the perfect long-term partner for your daily operations. Our service network can reach you wherever you are.

About Meckey

Meckey is a shareholding company in corn, wheat, potato, cassava, processing area, secialized in project engineering & construction, equipment manufacturing, technical support & sevices to customers worldwide.

Turnkey solutions

1. Corn grain to corn starch, gluten, germ/corn oil, fiber.

2. Wheat flour to vital gluten, A starch, B starch.

3. Potato(cassava) to potato(cassava) starch, cassava flour.

4. Starch to glucose, DMH, sorbitol, HFCS55.

5. Corn flour(rice) to glucose, DMH, sorbitol, HFCS55.

6. Modified starch, maltodextrin, potato flakes.

7. L-lysine, GSM.

Payment item

As a routine, 30% down payment, 70% by L/C at sight, 10% Bank guarantee supplied by Meckey. Workable details should be as per discussion based on the contract.

Delivery

Both your destination port or China port are available according to terms of contract. All exporting transactions can be on our duty.

Warranty

The warranty period of each item of equipment delivered shall be 12 months from the date of the signing ACCEPTANCE MEMO or 17 months from the date of shipment, whichever is earlier.

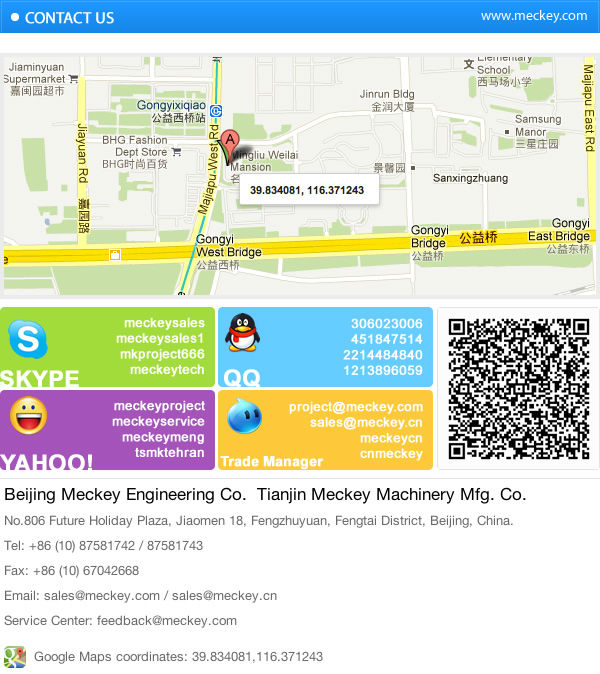

Welcome to contact us!!!

China

China