Jiangsu zhenxing drying equipment co.,ltd,this is Drying Equipment manufacture. We are specialized in development, manufacturing, and installation of dryers, mixers, granulators, grinders, conveyors, sieve and etc.

We follow a strict quality control procedure and we provide high quality products with prompt after sales services and technical supports.

Our products have been exported to North America, Pakistan, India, Philippines, Thailand, Nigeria, South Africa, Mexico, Colombia, Australia, Egypt, Vietnam, Russia, and other countries.

We truly believe that honesty, credibility, and integrity are the keys to build a widely successful business!

We are strictly complying with the international technical standards and quality management systems and we became the leading company in the drying equipment industry. We also dedicated in the environment protection and energy conservation industry.

Our company mission and top priority is to be our customer’s best business partner by consistently providing quality products and good after sales service. We will keep continuous improvement to our products and services in order to provide high quality equipment to our customers

We are providing the continuous training programs and safe working environments to all of our employees and we are making our best efforts to ensure the development of the company.

One of the most widely used drying systems is pneumatic drying and is also known as flash drying.The large surface area for heat and mass transfer and the high convective heat and mass transfer coefficients, which take place at these units, result in high drying rates and as a result, high drying capacity. The size of particulates to be dried is usually in the range of 10–500 mm. One of the features of these types of dryers is the relatively short contact time between the hot air and the particulate materials (0.5–60 s) at the drying section. Because of this the material temperature stays always low in the drying process.

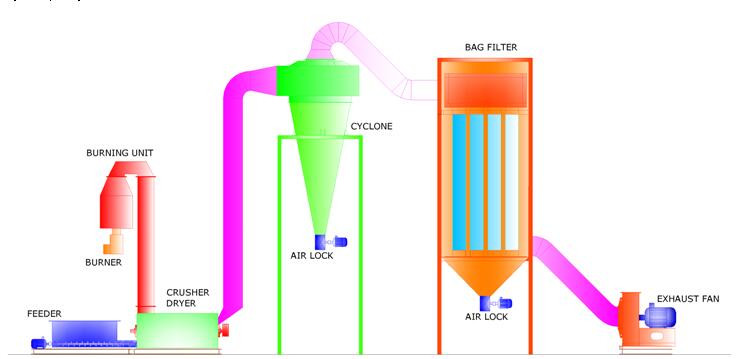

The simple flash drying system includes seven basic components: the heater, the wet material feeder, the dryer and crusher, the cyclone, the jet filter and a exhaust fan.

1. Adopt 2 lines tangential air enter into volute at the best position,it will improve or remove blind Angle of wind and also the wind in the weak

2.Be good at control the powder’s moisture,fineness,and hold time.for control the speed coordinating and unifying at spinning disk work with wind-enter ,it can ensure the outlet wind with low temperature,it will also reduce the energy consumption.

3. The special alloy steel be used in the rotary blade,the layout structure with unique,it have the character of small erosion,contact surface wide,cutting force strong.

4. Adopt the newly leak-proof structure,the main engine bearing life will be delay,and the bearing black with the cooling device.

5. In order to ensure the powder water content less than 0.5%,so increase the height than the original basis ,it also equip with spinning disk,it will make the powder quality and particle size meet with your requirement.

Due to the gas-solid corresponding relative velocity big,even though the mix temperature around 80~90℃,the powder temperature still on below 45℃ condition,it will help to packing and save energy.

| Model | tower diameter mm | air volume m³/h | evaporate capacity kg/h | power kw | height mm | install area m² |

| XZG-2 | 200 | 350-500 | 12-17 | 10 | 4000 | 15 |

| XZG-4 | 400 | 1150-2000 | 40-70 | 20 | 4800 | 20 |

| XZG-6 | 600 | 2450-4500 | 80-150 | 40 | 5800 | 28 |

| XZG-8 | 800 | 4450-7550 | 150-250 | 65 | 6500 | 35 |

| XZG-10 | 1000 | 7000-12500 | 230-425 | 85 | 7100 | 40 |

| XZG-12 | 1200 | 10000-20000 | 300-600 | 105 | 7800 | 52 |

| XZG-16 | 1600 | 18000-36000 | 600-1000 | 150 | 8800 | 80 |

| XZG-20 | 2000 | 28200-56500 | 1000-1500 | 230 | 10100 | 150 |

1.To effectively control final moisture content and fineness by spinning disk and the inlet wind speed.

2. The Spinning blade use the special alloy steel, which With less wear, wide contact surface, big cutting force etc

3.it is good at in deal with heat-sensitive materials, there are Cooling water protection device in the high temperature area, it avoid the material go to Coking discoloration in success.

4. Small system resistance, high thermal efficiency, good operating environment, the intensity of labor is low

5.The body tower uses new type seal structure, Extend bearing life cycle, and the Bearing casing also with a water circulating cooling device.

The flash dryer for Magnesium Hydroxide .

Title flash dryer for calcium carbonate

The flash dryer for Potassium Bicarbonate

Title fly dryer for fly ash

The flash dryer for zic sulfate

The flash dryer for Potassium Chloride

We solicit buyers opinions widely at the design and production stage of equipment; especially at the stage of plan and elevation arrangement, we give full consideration to buyers’ site conditions and public engineering conditions, and pay concurrent attention to the optimum combination when assuring the quality of equipment.

Installation and commissioning

After the equipment is delivered to buyers factory, we will dispatch full-time technical personnel to instruct buyers’ installation and to take charge of commissioning until normal use of the equipment.

Training

Before buyers use our equipment normally, our commissioning personnel will organize buyers’ relevant personnel to accept training, which covers the maintenance and care of equipment, timely repair of common faults, and procedures for operation of equipment.

Warranty

We provide one-year warranty for our equipment. For damage of equipment arising from non-artificial factors within the warranty period, we will provide repair service for free; and for damage of equipment arising from artificial factors, we will provide repair service in time and collect corresponding cost.

Maintenance and period

For damage of equipment after expiration of warranty period, we will provide on-site repair service within 24h/48h for enterprises inside/outside the province after receiving buyers’ notification. The service provided after expiration of warranty period is fee-based, and flat cost will be collected each time when the service is provided.

The pigment belt dryer equipment

This is belt dryer are customized to the Indian customer, Heat source:clean flue gases(heat exchanging type coal-fired hot air furnace, output quantity of heat is 160×104Kcal/h

Usage temperature:180-130℃

Circulating air volume:each section ≈18000 m3/h

Total installed power:120kW

Overall dimensions (L×W×H):19000×2400×3100mm

it is used widly in chemical filed.

The spray dryer equipment.

1. Name of material: coffee (instant)

2. Initial solid content: 35%

3. Output: 1000kg/h (final moisture: ≤3.5%)

4. Evaporation capacity: 1650kg/h

5. Inlet air temperature: 190°C (adjustable)

6. Outlet air temperature: 85°C (adjustable)

7. Heating method: heat-transfer oil heat exchange

8. Recovery method: fluidized bed central pipe discharging

9. Dedusting method: cyclone cluster + wet scrubber

The flash dryer equipment

1. Material name: Manganese sulfate monohydrate

2.Feed capacity:5000kg/h

3.Evaporate amount:≤750kg/h

4.Powder water content:0.5%

5.Temperature:inlet 250-280℃,outlet 70-90℃

4.Install power:192kw

5.Gas consumption:140M3/H

China

China