Applications of CT-C series industrial hot air tray dryer:

1. For drying powder,granule and sliced products in Food,Chemical and Pharmaceutical industry ;

2. Drying temperature: RT-350 degree C (adjustable)

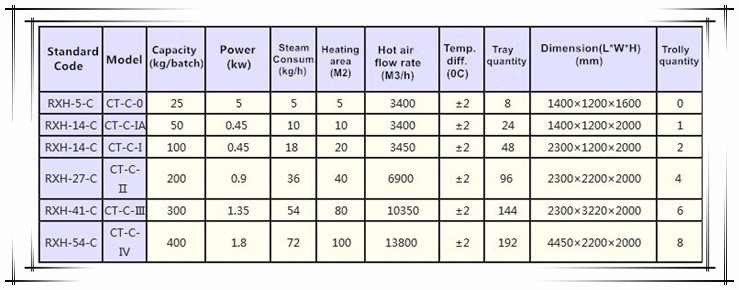

3. Drying capacity: 60-480 kg/batch

4. GMP design

5. Heat supply can be steam,electricity,hot water,hot oil and oil/gas fired hot air generator.

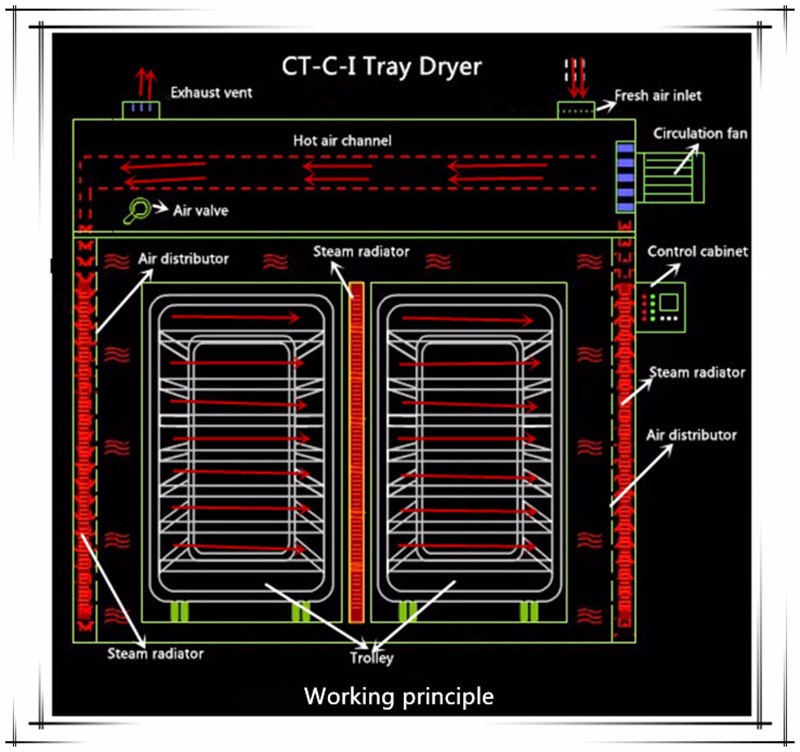

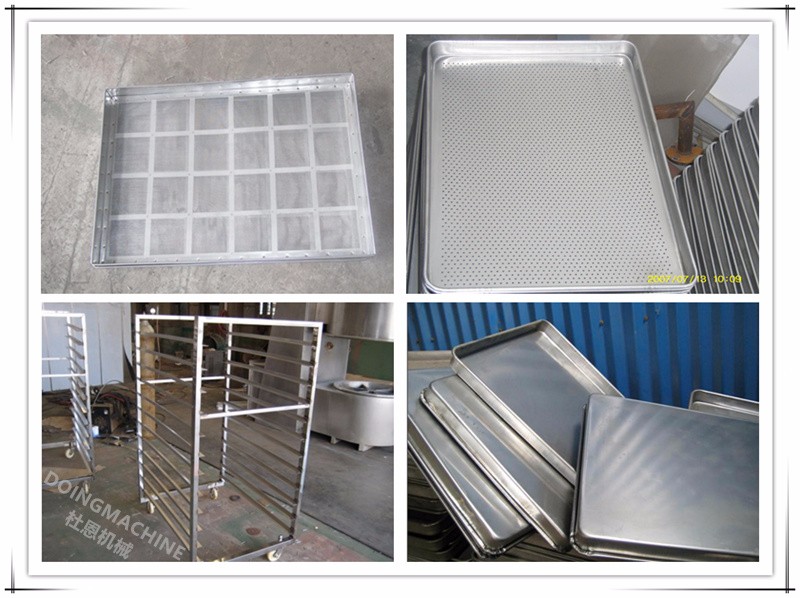

CT-C series industrial hot air tray dryer is a widely used convection chamber dryer. Inside the drying chamber trays loaded with wet material are placed on top of each other in trolleys.

In drying process, the fresh cold air is sucked into the drying chamber by the circulation fan and flow through the inner placed steam radiator (or electrical heating tubes) in the air channel to get required temperature. With the help of air distributor, the hot air evenly flow through each layer of trays for heat transfer and carry away the evaporated moisture. Most of the damp air flows back to the circulation fan for the next drying circulation while part of the damp air will be exhausted for energy saving.

After drying, open the chamber door and pull out the trolleys for discharging. The following drawing will show you how it works.

1. Flexibility in heat source: Our tray dryer can be heated by steam, hot water, electricity, thermal oil, oil/gas fired hot air generator to obtain different temperature according to special drying requirements.

2. Uniform drying: With the specially designed air distributor, the hot air flow in each layer of trays is very uniform.The temperature difference inside the drying chamber is less than ±2 ℃. Uniform air flow and temperature results in uniform drying.

4. Energy saving: Most of the hot air circulates inside the well insulated drying chamber and only part of it will be exhausted via the exhaust valve. The proportion of exhaust air depends on relative humidity inside the drying chamber.

5. Convenient operation: Control cabinet is installed on chamber body which can accurately set the drying temperature and hot air flow rate. Touch screen and press button panel are valuable.

6. GMP standard: Drying chamber is fully welded without dead corners to meet GMP standard.

1. Company profile:

China

China