Stainless Steel Material Hydro cyclone Separates Sand Filter

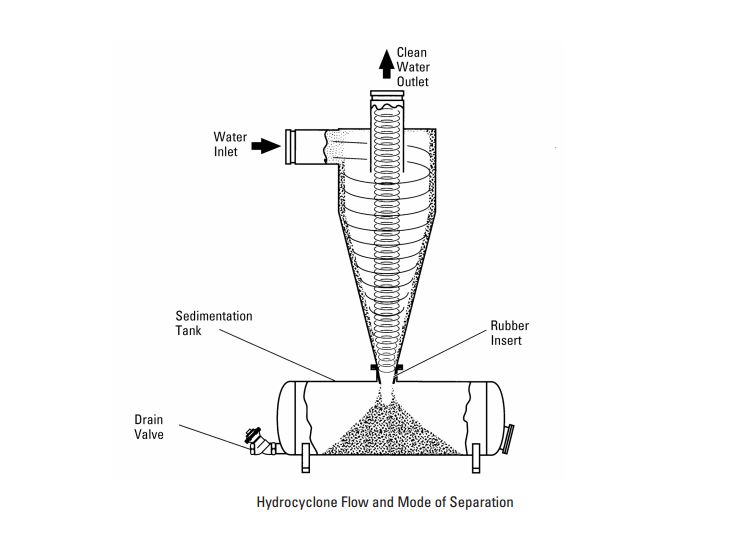

The dispersed particles move downward in a spiral path into an underflow chamber (sedimentation tank) while clean liquid moves upwards to the center of the spiral, towards the top outlet.

The Sedimentation Tank can be drained automatically with an automatic flushing kit (an electric valve, controller and small command filter).

Automatic flushing will not interfere with the proper functioning of the Hydrocyclone.

The Hydrocyclone has a 100 micron protective coating of extra durable polyester applied electrostatically and oven cured on a zinc-phosphate layer for maximal anti-corrosion protection.

Scope of application

1. Mainly applied to water quality treatment and control for the raw water and water supplying, such as: river water, well water desanding, coal washing water, mineral separation, solid-liquid separation, gas and liquid immiscible liquid separation.

2. It can be widely applied to the water source heating pump system, a heating water, central air conditioning cooling water, chilled water, steel, power, chemical and other industrial and mining enterprises, tap water, sea water, surface water, ground water.

Product characteristics:

1.No energy consumption, good sand removing effect, especially suitable for sand content higher system using.

2.Low cost, convenient installation and operation, safe and reliable operation, small size, processing a large quantity of water, small occupied area.

FAQ:

1. What is capacity(m3/h or gpm)do you require?

2. What is the material do you want?--SS or carbon steel?

3. What is the operation do you want?---By manual or automatic?

Technical parameters for cyclone sand filter(type II)

| Model of sand filter | Flow rate (T/h) | Water inlet (mm) | Water outlet (mm) | Ø diameter of cylinder (mm) | A1 (mm) | B1 (mm) | B2 (mm) | H1 (mm) | H2 (mm) | H3 (mm) |

| YLXC–40I | 25 | 40 | 25 | 273 | 220 | 113 | 220 | 640 | 140 | 860 |

| YLXC–50I | 40 | 50 | 25 | 273 | 220 | 108 | 230 | 680 | 140 | 910 |

| YLXC–65I | 50 | 65 | 25 | 325 | 220 | 124 | 240 | 780 | 140 | 1030 |

| YLXC–80I | 60 | 80 | 40 | 325 | 220 | 118 | 250 | 830 | 180 | 1095 |

| YLXC–100I | 100 | 100 | 40 | 377 | 220 | 134 | 260 | 920 | 200 | 1205 |

| YLXC–125I | 160 | 125 | 50 | 377 | 320 | 122 | 300 | 980 | 200 | 1310 |

| YLXC–150I | 200 | 150 | 50 | 478 | 380 | 150 | 360 | 1010 | 200 | 1410 |

| YLXC–200I | 250 | 200 | 50 | 620 | 440 | 200 | 430 | 1065 | 200 | 1550 |

| YLXC–250I | 300 | 250 | 65 | 720 | 500 | 225 | 520 | 1170 | 200 | 1750 |

| YLXC–300I | 500 | 300 | 65 | 820 | 580 | 274 | 590 | 1375 | 250 | 1990 |

Note:

H1: Height from top to sewage outfall.

L: Distance between two supporting legs.

H2: Height from top to ground.

TO SHANGHAI NIBONG QINGDAO TIANJING GUANGDONG PORT

We provide 24 hours online customer service.

Any inquiry about water treatment system, please feel free to contact me for further details!

Contact information:

Mobile phone: +86 13585066069

Email: yld AT jsyld.com.cn

Alibaba website: http://js-yilida.en.alibaba.com

Official website: WWW.zgyld.com

Guarantee period:1 year

After-sale service:800-827-87-226

China

China