Shijiazhuang Huanpai Machine Co.,Ltd is a professional manufacturer of all types of flour milling machine for wheat/maize/corn/grain.

Our factory has more than 30 years of experience in this field. we provide a turnkey project of our machinery, including special design, installation, commissioning and training workers.

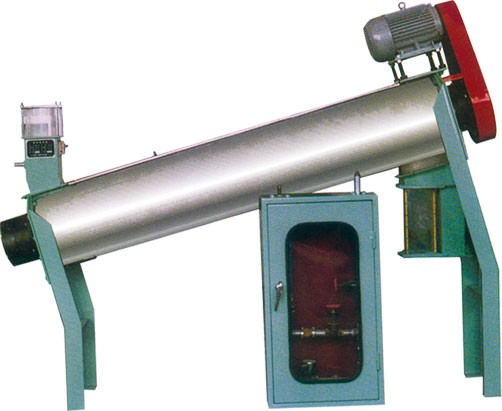

Automatic maize degerminator / maize germ separation

YXP1.0 series embryo selector

It is used to extract embryo from the mixture of the materials.

Complete fully automatic flour mill machine

| Item | Key points | Remark |

| 1. | Name | flour milling machine for making wheat,corn,maize flour |

| 2. | Capacity | 10-500T/D |

| 3. | Quality | Pass the quality management system ISO9001. Quality guarantee period of one year. |

| 4. | Service | turnkey project,special design, installation, commissioning and training workers,lifelong service to our product. |

| 5. | Spare parts | All of our new equipment to contain one year free spare parts |

| 6. | Workshop | according to the capacity |

| 7. | Power supply | according to the capacity |

| 8. | Color | Red,green,white,blue or according the customer’s demand |

| 9. | Cleaning system | beating, screening, destoner, magnetic separator and dampening. |

| 10. | Milling system | roller mill, plansifter, purifier, impact detacher, etc |

| 11. | packing and stacking | The packing part can be manual one also can be auto one, this can be designed according to requirement and machine capacity. |

| 12. | Storage | silos, or warehouse |

1. The clean part:

To clean out the middle and small impurity from wheat,corn,maize. e.g., dust, stone, magnetic material, wheat,corn,maize was bitten by insect and so on. Includes beating, screening, destoner, magnetic separator and dampening.this section is make the wheat,corn,maize to prepare for millling part and to protect the machinery as well.

2.The flour milling part:

(1) Mill: mill the wheat,maize,corn to break the integrity by the roller moving

(2) Sifter: to separate the flour and bran, also separate large size and small size to enssure flour quality.

3.Packing part

The packing part can be manual one also can be auto one, this can be designed according to requirement and machine capacity.

Main Features

2.Complete function precessiong as cleaning wheat, corn maize, peelling maize, and grinding wheat, corn maize into wheat,maize corn flour and maize corn grits and wheat,maize bran.

3.Clean wheat,corn maize to remove stone, metal, sand and all sorts of impurities.

4.Peel maize to remove maize skin, remove maize germ, remove black maize hilum. After cleaning and peeling, it prepares best maize material for further processing into maize flour or grits.

5.You can choose the mesh to make the flours fine as you requirement.

6. Simple structure in linear type ,easy in installation and maintation.

7. Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

8. High pressure double crank to control the die opening and closing.

9. Running in a high automatization and intellectualization,no pollution

10. Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

Our wheat flour mill machine can produce different grades of wheat flour according to client's demand. And the final production can be used for dark bread,thin bread,pasta,pizza,cake etc.

Our maize flour mill machine is a complete fully automatic machine. It can produce super fine maize flour, maize grits, germ and bran according to customer's demand.

Packing and Delivery

The machine will fixed by steel rope inside the container. Make sure it is in good condition when arrived destination.

Pre-sale services

* Special design.

* View our Factory.

Installation services

An experienced engineer will be send to project site to ensure the successful completion of each phase of the plant, which enables us to provide professional consultation, design, manufacture, installation and project management services.

Our products are exported to more than 30 countries in the world. For example: Australian, America, Algeria, Angola, Burkina Faso, Belgium, Canada, Congo, Cameroon, Ghana, Egypt, Philippines, Libya, Zambia, Kenya, Ethiopia, , Yemen, Malawi, Tanzania, Tajikistan, Afghanistan, Vietnam, Israel, Mozambique, South Africa, Sudan, Somalia, Togo, Uganda, Uzbekistan, Tajikistan, Rwanda, Kazajastan and other country.

FAQ

1. Q: Which kind of flour mill can you processed? And what about the capacity

-- A: we can offer wheat flour mill and maize / corn flour mill with the capacity 5T/24H ------1000T

2. Q: what is the basic processing step?

-- A: Full automatic line:Cleaning the raw material--Milling the material into flour--Packing the flour into bags.

3. Q: Which kind of wheat we can use in the processing line?

-- A: Durum wheat, Hard wheat, Soft wheat

4. Q: Which kind final products we can get from the wheat flour mill? And the usage of the products?

-- A: Semolina(very high gluten)--Pasta flour (gluten >13%)---Bread

Plain flour (gluten 9%-12%)--Noodle, Steamed bread Soft flour (gluten<8%)---Cake ,Biscuit

5. Q: Which kind of final products we can get from the maize / corn flour mill?

-- A: maize flour, maize grits (meal), maize germ, bran and animal fodder.

6. Q: Are you manufacturer or trading company?

-- A: We are professional wheat flour milling machine/maize flour mill manufacturer with more than 20years experience. And we have our own factory, welcome you come to China and visit our factory.

7. Q:Never engage in flour industry.Don't understand how to operate the flour milling machine?

--A:Your don't need to worry anything, Our professional Chinese engieer will go to you country to help you install the machinery and train workers.

*Training how to install the machine, training how to use the machine,maintainenance.

* Engineers available to service machinery overseas.Providing professional support for the consultation of engineering technology and technical problem.

8. Q:what is the basic processing step?

--A:Full automatic line,Cleaning the raw material--Grinding the material into flour--Packing the flour into bags.

9.Q: How does your factory do regarding quality control?

--A:Quality is priority. We always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment.

| SHIJIAZHUANG HUANPAI MACHINE CO., LTD | |

| Mobile (WhatsApp): 0086 15076162199 | Skype:hpmachinery |

| Email: hpflourmill(at)126.com | Tel:0086 311 87820292 Fax:0086 311 87820202 |

| http://www.huanpaimachine.com |

Other product

https://www.alibaba.com/product-detail/50-ton-per-day-low-price_60678843616.html

Animal feed machine

https://www.alibaba.com/product-detail/Chicken-cattle-poultry-feed-making-machine_60689876072.html

Farm machine

https://www.alibaba.com/product-detail/mini-corn-harvester-machine-for-sale_60658908454.html

China

China