Shijiazhuang Huanpai Machine Co.,Ltd is a professional manufacturer of all types of flour milling machine for wheat/maize/corn, Our production capacity is from 10 ton to 500 ton per day. We provide turnkey project of our machienry, including special design, installation instruction, commissioning and training workers.

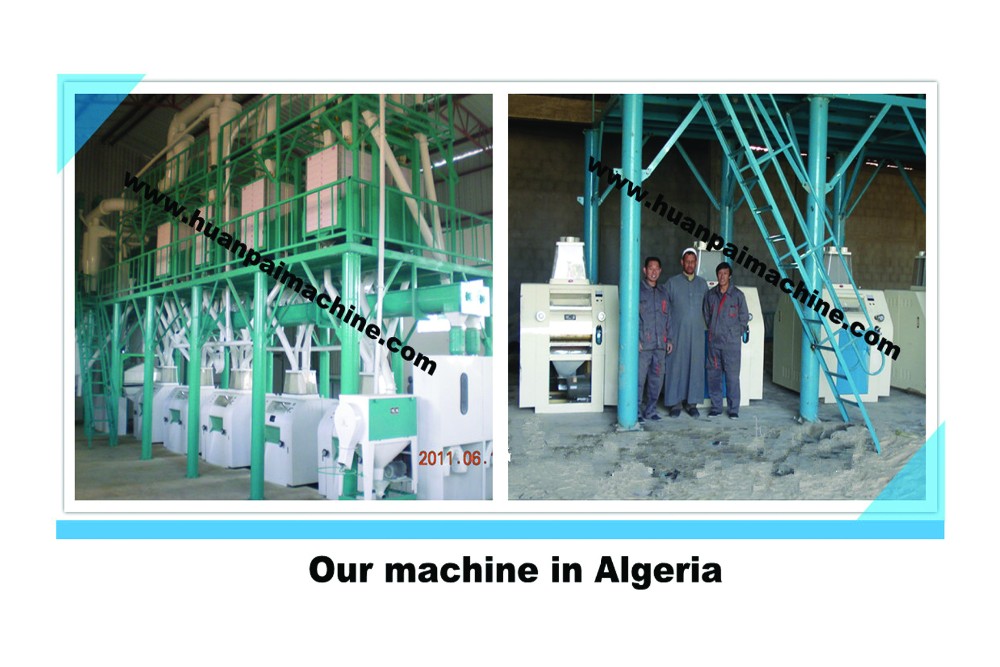

Our products are exported to Australian, America, Canada, Belgium, Egypt, Algeria, Zambia, Congo, Kenya, Ethiopia, Uganda, Yemen, Tanzania, Tajikistan, Afghanistan, Vietnam, Israel, Mozambique,Kazajastan and other country.

We have been in this field for more than 50years, and has grown into a a large supplier of feed machine with engineering automation control technology, product research, development and manufacturing, projects design and installment. Our equipment is widely exported to more than 30 countries and regions. Our professional engineers can design the machine as per your requiremnt. The complete set feed machine is suitable to small, middle and large feed plant to make feed powder, feed pellet for chicken, fish, sheep, cow etc.

Factory

Warehouse

Workshop

Workshop

certifications

All our machines are certified, attractive and reasonable price,You won't be disappointed to choose our company.

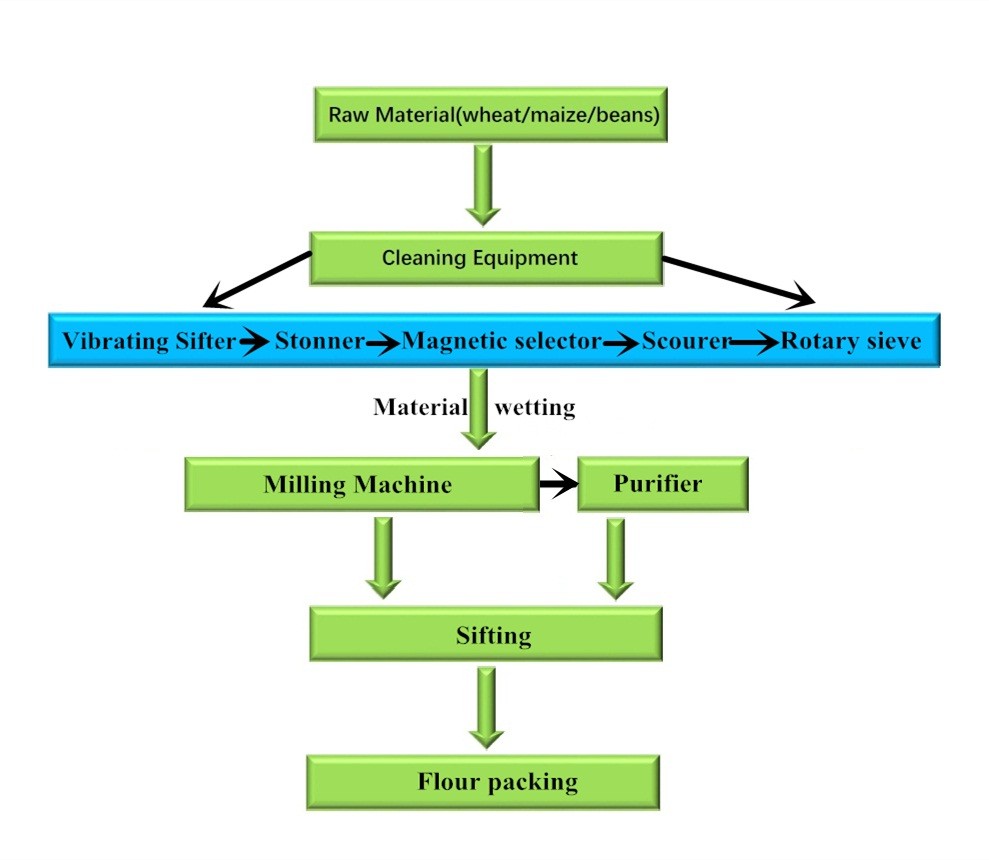

To clean out the middle and small impurity from wheat. e.g., dust, stone, magnetic material, wheat was bitten by insect and so on.Includes beating, screening, destoner, magnetic separator and dampening.this section is make the wheat to prepare for millling part and to protect the machinery as well.

2. Milling part

Include different number of mill and sifter to mill the wheat and separate the flour and bran

(1) Mill: mill the wheat to break the integrity by the roller moving

(2) Sifter: to separate the flour and bran, also separate large size and small size to enssure flour quality.

3. Packing part

The packing part can be manual one also can be auto one, this can be designed according to requirement and machine capacity.

4. PLC controlling system

To control the whole set of machinery to work well and showing the process of working

Main Features

2.Complete function precessiong as cleaning wheat, corn maize, peelling maize, and grinding wheat, corn maize into wheat,maize corn flour and maize corn grits and wheat,maize bran.

3.Clean wheat,corn maize to remove stone, metal, sand and all sorts of impurities.

4.Peel maize to remove maize skin, remove maize germ, remove black maize hilum. After cleaning and peeling, it prepares best maize material for further processing into maize flour or grits.

5.You can choose the mesh to make the flours fine as you requirement.

6. Simple structure in linear type ,easy in installation and maintation.

7. Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

8. High pressure double crank to control the die opening and closing.

9. Running in a high automatization and intellectualization,no pollution

10. Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Questions and Answer

Yes, We are a professional manufacturer for several years.

2.Where is your factory located?

Our factory is located in shijiazhuang, Hebei Province.

Quality is priority. We always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment.

4. Which kind of maize meal does your machine can milling?

All of our maize flour milling machine can milling different size of maize meal, like maize samp; maize grits; maize rice,maize meal;maize flour;fine flour

5. Which kind of wheat flour does your machine can milling?

The wheat flour mill can milling wheat to different kind of flour, like bakery flour,cake flour,semolina,etc

6. Never engage in flour industry.Don't understand how to operate the flour milling machine?

Your don't need to worry anything, Our professional Chinese engieer will go to you country to help you install the machinery and train workers.

* Training how to install the machine, training how to use the machine,maintainenance.

* Engineers available to service machinery overseas.Providing professional support for the consultation of engineering technology and technical problem.

7. Which kind of flour mill can you process? And what about the capacity?

we can offer wheat、maize/corn flour mill with the capacity 10T/24H--500T/24H.

8. what is the basic processing step?

Full automatic line,Cleaning the raw material--Grinding the material into flour--Packing the flour into bags.

9.Which kind of wheat can we use in the processing line ?

Durum wheat, Hard wheat, Soft wheat

10.Which kind final products we can get form the wheat flour mill? And the usage of the products?

Semolina very high gluten) -----Pasta

Strong flour (gluten >13%) ------Bread

Plain flour (gluten 9%-12%) -------Noodle, Steamed bread

Soft flour (gluten<8%) ------Cake ,Biscuit

11.Which kind final products we can get from the maize / corn flour mill ?

maize flour, maize grits (meal), maize germ, bran and animal fodder.

If you have any other questions, please don't hesitate to contact us!

| SHIJIAHZHUANG HUANPAI MACHINE CO., LTD | |

| Contact Name: | Emily |

| Mobile (whatsapp) | 0086 13833174510 |

| Skype | hpmachinery |

| Tel: | 0086- 311-87820292 |

| FAX: | 0086-311-87820202 |

| Email: | hpmachine at 126.com |

| hpmachinery at hotmail.com | |

| http://www.huanpaimachine.com |

China

China