Product Overview

Ceramic filter is mainly used for fine coal slurry recovery, equipped with an engine base, under the engine base setting a fine coal slurry liquid trough, in this liquid trough, equipped with liquid level controller, both ends with negative pressure water tank, one side of this water tank is equipped with negative pressure connected assembly fix, another side is vacuum pump pipeline connecting with a vacuum pump; on the engine base, there is a coal slurry recovery rotor, this rotor consists of main axle, multilevel ceramic filter disc, stripper plate, multisection effluent connecting pipeline piping support plate, negative pressure connecting assembly plate.

The rotor is located in liquid trough; the ceramic filter disc consists of many ceramic cavity micropore plates, those plates located in a same axes connect by the effluent connecting pipeline.

Main Structure

Ceramic filter is mainly consisting of roller system, mixing system, ore slurry feed and discharge system, vacuum system, filtrate discharging system, scraping system, back washing system, united washing system (ultrasonic cleaning, automatic matching acid cleaning), full-automatic control system, trough body, rack etc.

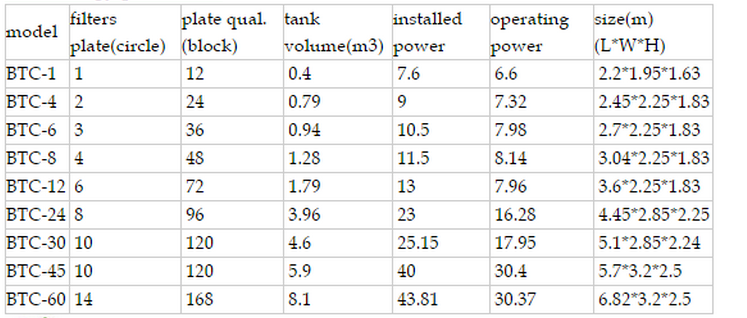

Technology Parameter

China

China