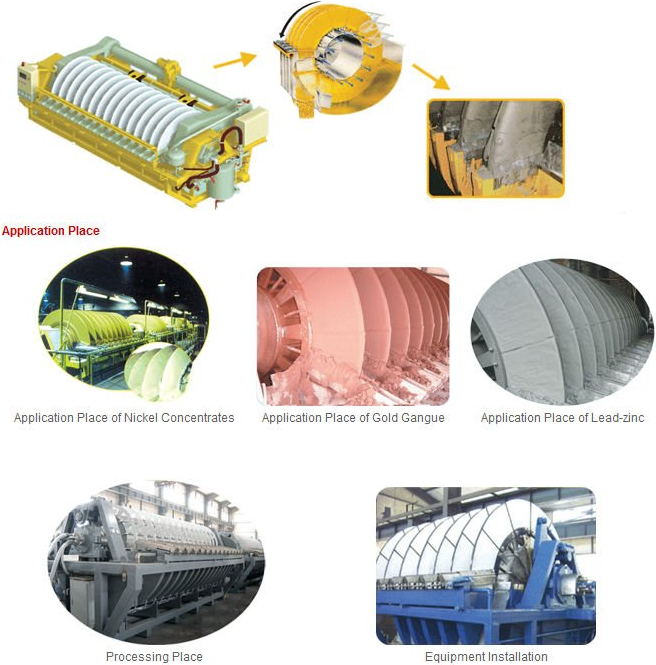

Product Overview

Ceramic filter is mainly used for fine coal slurry recovery, equipped with an engine base, under the engine base setting a fine coal slurry liquid trough, in this liquid trough, equipped with liquid level controller, both ends with negative pressure water tank, one side of this water tank is equipped with negative pressure connected assembly fix, another side is vacuum pump pipeline connecting with a vacuum pump; on the engine base, there is a coal slurry recovery rotor, this rotor consists of main axle, multilevel ceramic filter disc, stripper plate, multisection effluent connecting pipeline piping support plate, negative pressure connecting assembly plate.

The rotor is located in liquid trough; the ceramic filter disc consists of many ceramic cavity micropore plates, those plates located in a same axes connect by the effluent connecting pipeline.

Working Principle

Ceramic filter shape and mechanism is similar with the working principle of vacuum belt filter, under the effect of pressure difference, suspended matter particle are intercepted on the medium surface then form as filter cake while liquid outflow from filter medium to realize solid-liquid separation. The difference is filter medium, ceramic filter plate is with micropore that can produce wicking effect. That makes the wicking effect stronger than vacuum force, and micropore keep a state full of liquid. In any case, ceramic filter plate don't allow air go through, because of this reason, while solid-liquid separating, energy is saving and vacuum degree is high. Ceramic filter mainly consists of rotor, stirrer, scraper components, slurry trough, distributor, ceramic filter plate, vacuum system, cleaning system, automaticcontrol system etc.

Main Structure

Ceramic filter is mainly consisting of roller system, mixing system, ore slurry feed and discharge system, vacuum system, filtrate discharging system, scraping system, back washing system, united washing system (ultrasonic cleaning, automatic matching acid cleaning), full-automatic control system, trough body, rack etc.

Trough body uses corrosion resistant stainless steel, can load ore pulp. Stirring system is stirring mixing materials in trough body to avoid the rapid subsidence of materials. Ceramic filter plate is installed on roller, roller can be rotated by the drive of stepless speed change reduction gears.

Filter medium of ceramic filter is ceramic filter plate, doesn’t need filter cloth, that reduces cost of production. The 1mm gap between scraper and filter plate prolongs the service life while discharging.

Using back washing and united cleaning etc. methods, full-automatic control by PLC, equipped with inverter, liquid level meter etc. device. While starting up, ore pulp valve is monitored by level meter, it controls height of ore pulp level. When to high level, PLC control system rapidly opens filtrate pump outlet valve to drain water quickly. Ceramic can use long-range control or centralized control according to different requirement by customers.

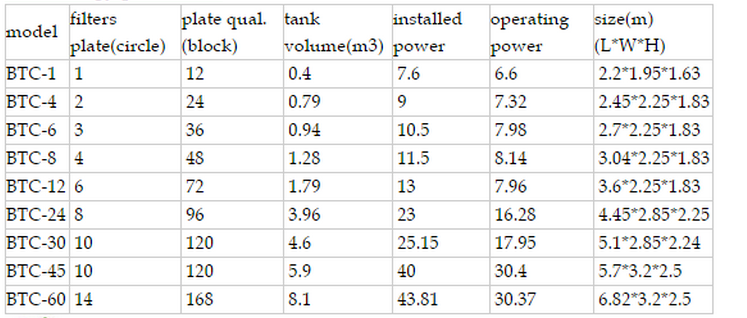

Technology Parameter

FAQ

1.Q:Are you a factory or trading company

A: We are a factory, we have rich experience for manufacuring water processing equipment for more than 10 years.

2.Q:Where is your factory located? How can I visit there?

A: Our factory is located in #1137, Zhucheng City, Shandong Province,China. It is about 2 hours from Qingdao airport. We can pick you up if you need, welcome to visit our factory.

3.Q: Do you have minimum order quantity request?

A: No minimum order, but it can get a discount if you order a large quantity.

4.Q: Do you have certificates?

A: Yes, we have ISO,SGS, BV certificate.

5.Q: Can you meet my special requirements for my products?

A: Yes, we have a professional design team. We can provide drawings according to your requirements.

6.Q:How to buy your idea products?

A:You can provide us your water sources, water quality, flow rate and ground area (connect us for more details).

7.Q:How to pay?

A: TT and L/C are acceptable and TT will be more appreciated. 30% deposit before producing, 70% balance before loading by TT.

8.Q:What is the delivery time?

A: It depends on order quantities. Generally speaking, the delivery time will be within 4 to 6 weeks.

9.Q: How to pack the products?

A: We use standard package. If you have special package requirements, we will pack as required, but the fees will be paid by customers.

10.Q: How to keep your equipments from corrosion?

A: We use the world-famous paint, like SigmaCoatings,PainBow,etc. What's more, we paint strictly according to the standard process.

11.Q: How do you manufacture your equipment ?

A:Our machining technology includes laser/plasma cutting, automatic welding,CNC cutting and bending.

12. Q:How to install after the equipments arriving destination?

A: We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you. However, the visa fee, air tickets, accommodation, wages will be paid by buyers.

China

China