Membrane filter use for hydration of brewery biological sludge,high efficient press filter with second squeezing prccess

1.Brief introduction:

The membrane plate type filter press ,whose filtration chamber is composed by membrane plate and the chamber plate ,with the help of the feeding pump,the solid and liquid are separated by the filter medium(filter cloth) .After the filter cake is formed,and then air or liquid goes into membrane plate.The second squeezing happens by membrane late bulk and lower moisure content.

Filter for viscous materials require higher moisture content and for users of this machine have their unique characteristics.

Plate with enhanced molded polypropylene, polypropylene plate with diaphragm mounted together, sturdy, secure, not easy fall off, long service life

Advantages of membrane filter press:

- High product throughput

- Reduction of the residual moisture of the filter cake

- Shorter filtration, wash and cake cycles

- Drier cakes means energy saving on cake drying and transportation

- The optimized cake structure facilities quicker and better washing results

- Varying product quantities and compositions present no problems to the membrane filter press

- High degree of automation, labor-saving and ease to operate:adopting PLC control system, including automatic keeping pressure, automatic pulling board, quick program functions,ect.

Specifications and technical parameters of membrane filter press:

| Type | (m2) Filter area | (mm) Filter plate size | (mm) Filter cake thickness | (L) Filter chamber volume | (pcs) Filter plate number | (Mpa) Filtrating pressure | (kw) Motor power | (kg) Weight | (mm) Dimension (L×W×H) |

| XG30/870-30U | 30 | 870×870 | 30 | 427 | 23 | 0.6 | 4.0 | 2680 | 3490×1250×1300 |

| XG40/870-30U | 40 | 534 | 29 | 3050 | 3880×1250×1300 | ||||

| XG50/870-30U | 50 | 676 | 37 | 3465 | 4400×1250×1300 | ||||

| XG60/870-30U | 60 | 818 | 45 | 4003 | 4920×1250×1300 | ||||

| XG70/870-30U | 70 | 960 | 53 | 4584 | 5240×1250×1300 | ||||

| XG80/870-30U | 80 | 1103 | 61 | 5082 | 5760×1250×1300 | ||||

| XG50/1000-30U | 50 | 1000×1000 | 665 | 27 | 0.6 | 4.0 | 4352 | 4270×1500×1400 | |

| XG60/1000-30U | 60 | 808 | 33 | 4480 | 4770×1500×1400 | ||||

| XG70/1000-30U | 70 | 950 | 39 | 5263 | 5130×1500×1400 | ||||

| XG80/1000-30U | 80 | 1093 | 45 | 5719 | 5560×1500×1400 | ||||

| XG100/1000-30U | 100 | 1378 | 57 | 6555 | 6410×1500×1400 | ||||

| XG120/1000-30U | 120 | 1663 | 69 | 7466 | 7260×1500×1400 |

Pictures to show you principle of the second sequeezing process

01.After the filter cake are formed ,the diaphragm valve open and air or liquid (usually water)goes into the membrane plate

02.The membrane plate filled with air or liquid,so the membrane plate is expanded, this can make the second squeezing of the filter cake,and lower the moisture content

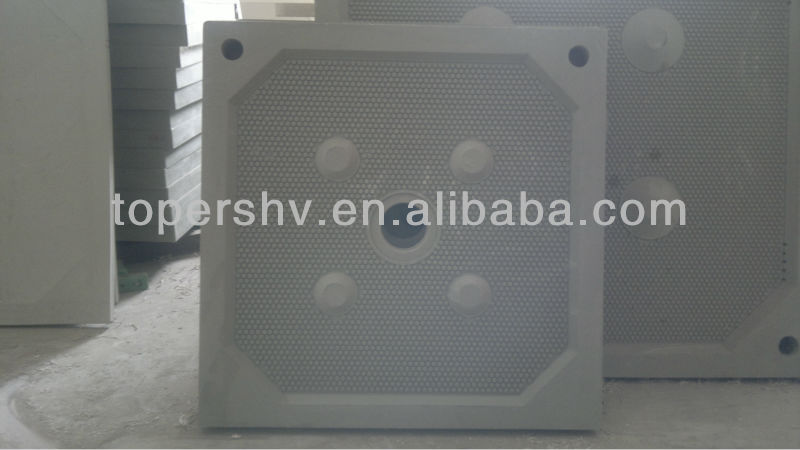

Membrane plates of membrane filter press are made from RPP material moulded. Diaphragm and RPP are enchased togerher to become firm, so they do not fall off easily and have a longer service life.

Membrane plate of membrane filter press

Membrance matching plate of membrane filter press

Below device is used for the automatic type ,which can pulling plates one by one automatically ,we called the pulling plates device.

Plate shifting control switch of membrane filter press

Limit switch of membrane filter press

Master control of membrane filter press

We provide you reliable and fast package and variety kinds of transportation way to insure you get the goods in time and safely.

1.We have professional person on line to advise you the most suitable type of machie according to your requirement.

2.Provide you comprehensive.easy-understanding and detail information and technical data about the machie you interested;solve your confusions or questions about the machine

3.Arrange the schedule if you pay a visit to our factory

4.Our technical engineer can also guide the installation,testing ,solve problems and so on in your country if required.

Zhengzhou Toper is the leading supplier of industrial equipment in China, and also the professional exporter and

service provider of filter and separation equipment . Also we focus on full service for filtering project from design

to after-sale service and fast supply of spare parts.

Since 2006, Zhengzhou Toper has supplied products ans service to over 200 enterprises of 30 more countries

ans areas excluding China mainland

Southeast Asia:Indonesia, Malaysia, Philippines ans Thailand:

West Asia:Turkey, Uzbekistan and Tajikistan;

Northeast Asia: South Korea, Mongolia,

Middle East:: Israeli, Palestinian, Oman, Bahrain, Iran”

Europe: Russia, Italy, Spain, Ukraine, Finland, Poland, Romania ;

North America: Canada, America

South America:Mexico, Guatemala, Argentina, Brazil, Chile, Peru, Bolivia;

Africa: South Africa, Algeria and so on.

All of our products

1.Program-controlled automatic filter press

2.Membrane filter press

3.Hydraulic compress filter press

4.Mechanical compress filter press

5.Jack filter press

6.Cast iron plate and frame amber filter press

7.Stainless steel plate and frame filter press

8.Round plate filter press

9.Cotton cake filter press

10.Cardboard filter press

11.DY belt filter press

12.DYX high pressure belt filter press

13.DNY rotary drum thickning/dehydrating belt filter press

14.Triple-belt thickning and dehydrating filter press

15.SS type three-foot upper discharge centrifuge

16.SD type three-foot and filter bag hoist discharge centrifuge

17.PD type filter bag hoist discharge centrifuge

18.Centrifuge of up discharge, three foot, clean series SSB, SB

19.SX type manual top discharge centrifuge

20.PS type manual top discharge centrifuge

21.SGZ type automatic scraper bottom discharge centrifuge

22.PGZ type scarper bottom discharge centrifuge

23.LW series decanter centrifuge

24.Tubular centrifuge

25.Multi-layer stainless steel frame filter

26.Bag filter

27.Diatomite filter

28.Filter late

29.Filter cloth

30.Vacuum disc filter

Membrane filter use for hydration of drewery biological sludge,high efficient press filter with sencond squeezing prccess

Membrane filter use for hydration of drewery biological sludge,high efficient press filter with sencond squeezing prccess

Membrane filter use for hydration of drewery biological sludge,high efficient press filter with sencond squeezing prccess

China

China