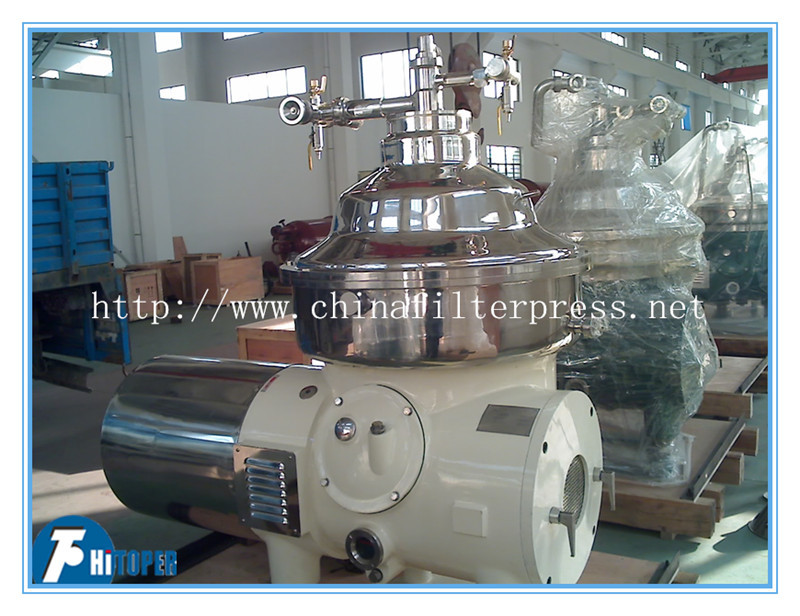

Industrial clarify disc centrifuge for sale

01.Brief introduction

The Industrial clarify disc centrifuge for sale , is a high efficiency, large output, advanced automation equipment.suitable for low solid content slurry, a smaller proportion of poor separation of immiscible liquids, pharmaceutical, food, chemical, biological products, beverage products and other necessary equipment industries.

02. Different classify

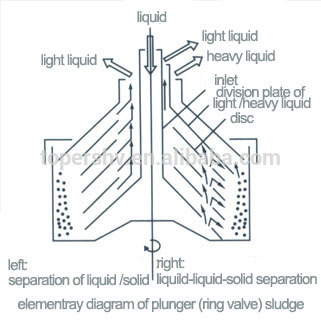

Disc separator according to the separation mode can be divided into three-phase separator (liquid - liquid - solid) disc separatoand two-phase separation (liquid - solid) disc separa.

While the disc type automatic slag separator in different ways based on, can be divided into manual type automatic slagging disc separator and fully PLC controlled automatic slagging disc separator

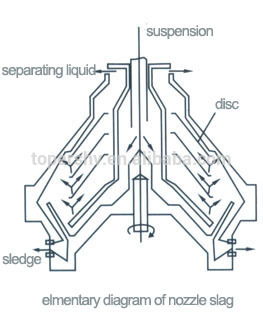

According to the disc separation inside the slag film in different ways, disc separator can be divided into piston slag disc separator with nozzle slag separator, and can be selected according to the characteristics of slag material way.

Working principle:

Thermal coupling through the drum motor drive to do high-speed rotation around the main axis, the liquid feed pipe from the top center of flow to the bottom of the drum, the disc surface diversion hole trend to drum wall, the centrifugal force field, compared with liquid weight of solid phase formation of sediment sink to the drum wall, light liquid pumps to the heart by the light liquid exit discharge.

Heavy liquid within the cone along the disc tend to drum wall, then up to the heavy liquid flows through the heart pump discharges them from the heavy liquid, thus completing the heavy liquid and light liquid separation.

Different structure type:

The drum is the most important part of the separator, as shown in the figure, the drum shell and drum cover locked together by the locking ring. The drum is equipped with a distributor, a disc holder and a disc set. Above the disc set is a disc cover, the neck of the disc cover and the liquid level ring composed of light phase pump room. The top of the disc cover and the pump cover form a heavy phase cardiac pump chamber. The heavy phase pump is equipped with an interface specific gravity ring for adjusting the interface between light and heavy. The drum body is also equipped with a sliding drum, drum body with the lower part of the slip ring and spring seat, slip ring and spring seat is equipped with a set of effect spring.

Drum shell and the upper part of the slip ring to open the water chamber.

Drum shell and bottom part of the sliding drum form the sealed water chamber.

Function of the disc centrifuge separator :

Separation function

Fluid flow inside the drum:

The mixed liquid is separated from the liquid inlet through the inlet pipe into the cloth tray and is reallocated into the disc group, and the solid particles and the water move along the conical surface of the disc toward the drum wall. Separation process, the separation of the heavy liquid through the lid and the disc between the cover through the flow through the ring into the heavy liquid concentric pump chamber by the heavy liquid heart pump through the heavy liquid export machine, the light along the disc to the center of the drum movement, and then through the liquid level ring into the pump chamber light from the light liquid heart pump through the light liquid outlet from the machine outside

Water sealing of the separation treatment process :

In order to prevent the mixed liquid from flowing through the disc edge through the heavy liquid passage, or to generate static electricity at the time of starting up, it is necessary to add sufficient water to the drum before feeding the mixed liquid to the drum. Water seal is completed, to add to the drum mixture, due to the hydraulic pressure balance,between the heavy and light liquid interface formation. The position of the interface can be adjusted by changing the gravity ring diameter.

The specific gravity ring determines the position of the light and heavy liquid interface in the drum. When separating, the specific gravity ring is selected according to the density of the mixture.

Slag discharging function

Normal separation:

Sealed water valve open once every minute, so that the bottom of the sliding drum filled with water, due to the role of centrifugal force, the water in the bottom of the sliding drum produced a huge hydraulic pressure on the sliding drum, which is greater than the drum cavity material resulting hydraulic pressure, so the sliding drum is supported to withstand the nylon ring, to ensure that the drum cavity is closed in the case of separation. Slip ring through the reset spring to produce the force to ensure that the sealing valve is closed, light and heavy phase outlet valve is open. The separation is carried out and the solid phase is separated and accumulated on the drum wall.

The slagging cycle begins:

The feed valve is closed, the slag discharge valve is opened, the slag water enters between the slip ring and the drum, the hydraulic pressure exceeds the reset spring force, and the slip ring moves downwardly, so that the seal valve is opened and the bottom of the slide drum is operated The water is discharged, while the sliding drum to move down, then the drum on the slag, the drum of liquid, slag through the drum wall of the slag discharge mouth outside the drum, about 5 seconds after the slip ring to move up , And closed the three sealing valve, slag discharge work through the hole on the slip ring outside the drum. Seal valve open, sealed water through the sealed water channel, gradually filling the bottom of the piston, the hydraulic pressure gradually becomes larger, closed the drum.

Dumping cycle ends (return to normal separation): Seal water valve open, into the water seal, until the heavy phase outlet water, feed valve open, return to normal separation.

More pictures of different types of the disc centrifuge separator :

Other type of Toper's separator centrifuge:

We provide you reliable and fast package and variety kinds of transportation way to insure you get the goods in time and safely.

1.We have professional person on line to advise you the most suitable type of machie according to your requirement.

2.Provide you comprehensive.easy-understanding and detail information and technical data about the machie you interested;solve your confusions or questions about the machine

3.Arrange the schedule if you pay a visit to our factory.

4.We can also send our technical engineer to your area guide the installation , debugging and solve practical problems if required.

You can find more realted machines as below:

1. Program-controlled automatic filter press

2. Membrane filter press

3. Hydraulic compress filter press

4. Mechanical compress filter press

5. Jack filter press

6. Cast iron plate and frame/chamber filter press

7. Stainless steel plate and frame filter press

8. Round plate filter press

9. Cotton cake filter press

10. Cardboard filter press

11. DY belt filter press

12. DYX high pressure belt filter press

13. DNY rotary drum thickning/dehydrating belt filter press

14. Triple-belt thickning and dehydrating filter press

15. SS type three-foot upper discharge centrifuge

16. SD type three-foot and filter bag hoist discharge centrifuge

17. PD type filter bag hoist discharge centrifuge

18. Centrifuge of up discharge, three foot, clean series SSB, SB

19. SX type manual top discharge centrifuge

20. PS type manual top discharge centrifuge

21. SGZ type automatic scraper bottom discharge centrifuge

22. PGZ type scarper bottom discharge centrifuge

23. LW series decanter centrifuge

24. Tubular centrifuge

25. Multi-layer stainless steel frame filter

26. Bag filter

27. Diatomite filter

28. Filter late

29. Filter cloth

30. Vacuum disc filter

Industrial clarify disc centrifuge for sale

Industrial clarify disc centrifuge for sale

Industrial clarify disc centrifuge for sale

China

China