Product Application

The machine adopts full close structure with primary middle and high effect air filter to fit one hundred thousand grade requirement, the tower body is provide cooling air jacket to make wall temperature less than 80 degree, when the material stops on wall will not to be preheated and softened, it increases the powder collection rate (95%) and will not appear mixing and sticking wall phenomenon.

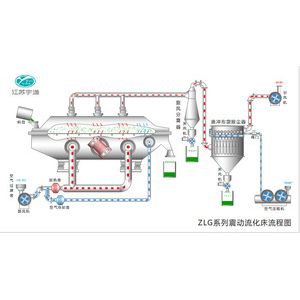

Basic principle: High Speed centrifugal atomizing for the Coconut Milk is an application of centrifugal atomizing technique. It also uses high-speed atomizer to make liquid material into foggy droplet to contact with hot air fully to finish instant drying and get final powder products.

The ZPG Coconut Milk Spray Dryer is specially designed to solved the problems which previous LPG spray dryer meets during drying Probiotics products as follows:

1) Raw material sticks to wall and powder collection rate is low.

2) Raw material stays on wall for long time, resulting in coking and deterioration phenomenon.

3) It is difficult to clean and can not meet GMP requirement.

4) Low in output: LPG-150 type dryer can only process 50-60kgs/h of raw material liquid.

In view of above situation, according to property and process requirement of traditional Coconut Milk, our factory has researched and designed the special spray dryer the Coconut Milk liquid and got patent. It solves the traditional difficult problems in drying the extract and product color after drying is good. The dried raw material does not degenerate too. It raises the economic benefit for user greatly. There are special features as below compared to ordinary LPG type spray dryer.

1) Adopt three grade air filter, the inlet air reaches one hundred thousand grade

2) Adopt wall cooling device, the temperature of inner wall will be less than 80 degree, even if materials stay on inner wall surface, it will not be burnt and softened.

3) Its whole volume is 3.5 times of standard LPG high speed spray dryers.

4) Adopt quick-open washing device, it can meet requirement for varieties production, the CIP auto cleaning device can also equip if needed.

5) Adopt wet duster and no powder dust leak out. It is in conformity with the requirements of environment protection.

6) Air sweeping device is optional, the clean effect is satisfied for some product.

7) Adopt PLC control and touch screen system to display system processing.

8) Dehumidifier and centralized collect system can be used to avoid re-wetting and softening.

Main Features

1) The tower body is equipped with cool air jacket to reduce inside tower temperature and eliminate product preheating and soften phenomenon.

2) The atomizer on top of tower is equipped with cooling device to reduce atomizer temperature, at the same effectively eliminate material return to the top in eddy current and avoid preheat coking phenomenon.

3) Tower body and pipeline is equipped with manual quick-open cleaning hole and drainage hole. CIP automatic cleaning device can also equipped if needed.

4) A automatic control constant temperature feeding tank can be equipped.

5) Manual high pressure washing tools can be offered as accessories together with spray dryer.

6) All product contact parts are made with Stainless Steel, (or whole parts with stainless steel)

7) Product collect way adopts two grade cyclones and water film duster.

8) Air inlet temperature is automatic and continuous control which is interlocked with feeding.

9) An air sweeping device can be optional for some products.

Machine Parts

Name: Observation door

Brand: Yuzhou

Original: China

The main tower adopts the quick-open cleaning door, the clean-up door adopts the integral design, and is optimized on the manhole design of the Danish Nile spray tower, and our company has applied for a new practical patent (patent number: 201320350821.9) Door operation is simple and convenient, while ensuring absolute sealing, to ensure that the manhole wall will not keep the material which properly prevent contamination.

Main Features

Name: Dehumidifier

Brand: Yuzhou

Original: China

The dehumidifier refrigerant could insert 25 degree coolant air, and combines with 85 degree output powders. Use pneumatic conveying which could properly prevent the final ingredients softening and re-wetting caused conglomerate, and could guarantee the extract fragrency and quality.

Machine Parts

Name: Inlet air spiral air distributor

Brand: Yuzhou

Original: China

Main Features

Name: Sprial Rotating Discharge material

Brand: Yuzhou

Original: China

The material spiral rotating discharge by air volume, and generate negative pressure and siphon off the material which could properly prevent the congestion of powder

Pre-Sales Service

* Inquiry and technical consulting support.

* Sample tentative testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

| Introduction | |

| Establish year | 2000 |

| Location | Jiaoxi Zhenglu Town, Changzhou City, 213116, Jiangsu China |

| Enterprise Details | Established in 2000, Jiangsu Yutong Drying Engineering Co., Ltd is National and new technology enterprise by national high and new technology enterprise and famous enterprise specialized in drying, mixing, grinding, granulating, extracting machines. |

| Contact information | |

| Contact person | Mrs Annie Shi |

| Occupation | Foreign Trade Executive |

| Contact Details | Skype: annieshi2012 Whatsapp/Wechat/Mobile Number: +86 15861862227 QQ: 1442341010 Email: jsyutongdry AT hotmail.com Http://www.china-yutong.com Jiangsu Yutong Drying Engineering Co., Ltd |

China

China