ZDG Series Vibration Fluid Bed Dryer for Borax

1.High effection save energy,heated evenly

2.Convenient in installation and maintenace low noise

3.Use wide in chemical industry,light industry,pharmaceutical,foodstuff...

Description

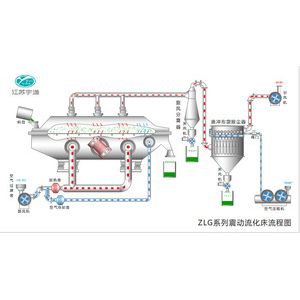

ZDG vibrating fluid bed dryer adopts fully enclosed structure, which can effectively prevents cross pollution between materials and air, resulting in a clean working environment. The materials enter into the drying machine via feed inlet, under the effect of exciting force, the materials along the horizontal direction proceed forward continuous movement. Hot air from top to bottom or from bottom to top conducts heat transfer with the materials through fluidized bed, thus uniformly drying the materials. Hot air passes through the pore plate of fluidized bed to transfer the heat, and then expels from the air outlet and the dried materials are expelled from the discharge opening.

Application

ZDG vibrating fluid bed dryer can be widely used drying and cooling the materials in the pharmaceutical, food, nourishment, chemical, pesticide, plastic, grain and oil, slag, salt manufacturing, sugar and other industries. The materials include all kinds of additives, chicken powder, gourmet powder, granulated sugar, salt, mineral powder, dispersing agent and so on.

Features of ZDG Drying Machine

1. With symmetrical fluidization, the users can obtain uniform drying and cooling products.

2. ZDG vibrating fluid bed dryer has good adjustability and wide adaptability. The material thickness, movement speed and total amplitude can achieve stepless regulation.

3. Our drying machine has little damage to the material surface, so it is applicable for drying fragile materials. Irregular material particles will not affect the working effect.

4. ZDG vibrating fluid bed dryer has high mechanical efficiency, high thermal efficiency and good energy-saving effect, thereby it can save 30 to 40% energy than common drying devices.

5. When the drying materials with high moisture content or need mass production, it can adopt tandem method to meet the requirements of users.

Technical Parameters of Fluid Bed Drying Machine

| Model | Fluidized Bed Area (m2) | Inlet Air Temperature (ºC) | Outlet Air Temperature (ºC) | Evaporation Capacity (kg/h) | Vibrating Motor | |

| Model | Power(kw) | |||||

| ZDG3×0.3 | 0.9 | 70 to 140 | 40 to 70 | 20 to 35 | YZS8-6 | 0.75 × 2 |

| ZDG4.5×0.3 | 1.35 | 70 to 140 | 40 to 70 | 35 to 50 | YZS10-6 | 0.75 × 2 |

| ZDG4.5×0.45 | 0.025 | 70 to 140 | 40 to 70 | 50 to 70 | YZS15-6 | 1.1 × 2 |

| ZDG4.5×0.60 | 0.7 | 70 to 140 | 40 to 70 | 70 to 90 | YZS15-6 | 1.1 × 2 |

| ZDG6×0.45 | 0.7 | 70 to 140 | 40 to 70 | 80 to 100 | YZS15-6 | 1.1 × 2 |

| ZDG6×0.6 | 3.6 | 70 to 140 | 40 to 70 | 100 to 130 | YZS20-6 | 1.5 × 2 |

| ZDG6×0.75 | 4.5 | 70 to 140 | 40 to 70 | 120 to 170 | YZS20-6 | 1.5 × 2 |

| ZDG6-0.9 | 5.4 | 70 to 140 | 40 to 70 | 140 to 170 | YZS30-6 | 2.2 × 2 |

| ZDG7.5×0.6 | 4.5 | 70 to 140 | 40 to 70 | 130 to 150 | YZS30-6 | 2.2 × 2 |

| ZDG7.5×0.75 | 5.625 | 70 to 140 | 40 to 70 | 150 to 180 | YZS40-6 | 3.0 × 2 |

| ZDG7.5×0.9 | 6.75 | 70 to 140 | 40 to 70 | 160 to 210 | YZS40-6 | 3.0 × 2 |

| ZDG7.5×1.2 | 9.0 | 70 to 140 | 40 to 70 | 200 to 280 | YZS50-6 | 3.7 × 2 |

| ZDG7.5×1.5 | 11.25 | 70 to 140 | 40 to 70 | 230 to 330 | YZS50-6 | 3.7 × 2 |

| ZDG8×1.8 | 14.4 | 70 to 140 | 40 to 70 | 290 to 420 | YZS75-6 | 5.5 × 2 |

Company introcuction

1.We use high-end imported brands of instruments and processing machines, to create superior quality machine for you ; yutong makes you feel free about the after-sales service.

2.We provide the spare parts with the cost of the spare parts themselves for life long time .

3.We can make the machine based on the customer requirements .

4.We have strong team ,and can help customer to design his process of the product .

5.Guarantee /warranty :1year. calculating from the day of successful installation and commissioning.

Factory inside

Processing&Our team

Service

Pre-service

Introduce the product to the customer in detail,answer the question raised by customer carefully;

Sale service

1.Ensure product with high quality and pre-commissioning before delivery;

2.Delivery on time;

3.Provide full set of documents as customer’s requirements.

After-sale service

Provide considerate services to minimize clients’ worries.

1.Assist clients to prepare for the first construction scheme;

2.Install and debug the equipment;

3.Train the first-line operators;

4. Examine the equipment;5.Take initiative to eliminate the troubles rapidly;

6.Provide technical support;

7.Establish long-term and friendly relationship.

Service commitment

1. Provide clients one-year warranty to make sure the machine work well;

2.We always keep certain inventory level of spare parts, which means the replacements can be sent to you timely;

3.Send every client a preferential quotation.

Centrificate

Exhibition

FAQ

1.Are you a manufacturer ,trading company or a third party

We are a manufacturer ,we set in 2000.

2.Where is your factory located

Our company is located in Changzhou city ,Jiansu province,China .it is In the middle of Shanghai and nanjing

China

China