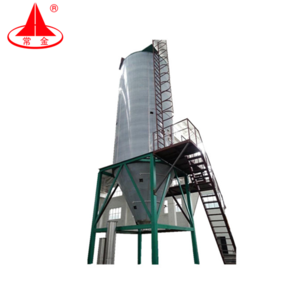

Plastic and Resin Spray Drying Equipment/ Spray Dryer

Description

Spray drying process is the widest used in the liquid forming process and in drying industry. The drying technology is most suitable for powder, particle products from solution, emulsion, SC and pumpable paste states material. For this reason, when the particle size and distribution of the final product, their residual water contents, the stacking density and particle shape must meet the precision standard, spray drying process is one of the most desired processes.

Features

1. At a high speed of drying, after spraying of the material liquid, the surface area will be increased greatly. In the hot air flow, 95%-98% of water can be evaporated at a moment. The time of completing the drying needs only several seconds.

2. This is especially suitable for drying the heat sensitive materials. Its final products own good uniformity, mobility, dissolving capacity. And the final products are high in their purity and good in their quality.

3. The production procedures are simple and the operation and control are easy. The liquid with the moisture contents 40-60% (for special materials, the contents may reach 90%) can be dried into the powder of particle products for one time. After drying, there is no need for crushing and sieving, so as to reduce operation procedures in the production and to enhance product purity. The product particle diameters, looseness and water contents can be adjusted through changing the operation condition in a certain scope. It is very convenient to carry out control and management.

Application

Chemical Industry Sodium fluoride(potassium),alkaline dyestuff and pigment, dyestuff intermediate, compound fertilizer, formic silicic acid, catalyst, sulphuric acid agent, amino acid, white carbon and so on.

Plastics and resin AB,ABS emulsion,uric acid resin,phenolic aldehyde resin,urea-formaldehyde resin,formaldehyde resin,polythene,poly-chlotoprene and etc.

Food Industry Fatty milk powder,protein,cocoa milk powder,substitute milk powder,egg white(yolk),

Food and plant,oats,chicken juice,coffee,instant dissoluble tea,seasoning meat,protein,soybean,peanut protein,hydrolysate and so forth.

Sugar, corn syrup, corn starch, glucose, pectin, malt sugar, sorbic acid potassium and etc.

Ceramic aluminium oxide,ceramic tile material,magnesium oxide,talcum and so on.

China

China