LPG High-Speed Centrifugal Spray Dryer Price For Sale Atomizer

Thank you for viewing this page! Here you can check our Different Kinds of Drying Machine! Here at Macat, we can make any items you need with great quality and service. So pls contact us if these are interesting to you.

Description:

1. Drying speed is fast.

2. The product has good degree of homogeneity, fluidity and solubility.

3. Production pocess is simple and operation is easy to control.

4. Adops mechanical type centrifugal atomizer, driven by gear, speed is stable and can ensure the uniform distribution of forgdrops.

5. The direction and angle of hot air distributor adopt adjustable structure, it can ensure the forgdrop contact with hot air fully.

6. Elbow is made of sanitation degree steel pipe, it can avoid the material blocked in the elbow.

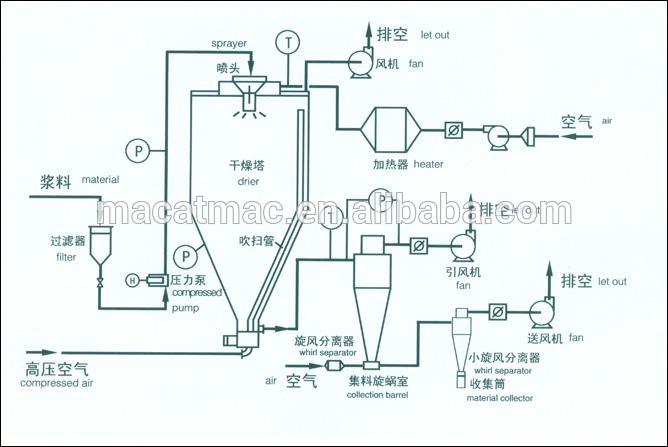

1. Atomization: Atomizing system must insure fogdrops distributing unifoemly

2. Contact of hot airflow and fogdrops: When enough hot air enter into drying tower, the flow way and angle have to considered, no matter co-current flow, adverse current or mixed flow, must insure the sufficient heat exchange, it is cruicial.

3. The angle design of pipelines and cone: It is very important to select the suitable angle, here we would like to share our experience from production of thousands of this equipments.

1.Foodstuff:

Amino acid, vitamin, egg powder, bone powder, flavouring, protein, milk powder, blood powder,soy sauce powder, coffee, tea powder, glucose, pentadiene carboxylic acid, pectin, flavours, vegetable juice, yeast, starch, etc.

2.Ceramic:

Alumina, zirconia, magnesium oxide, titania, pottery clay, china clay, all kinds of magnetic porcelain and metal-oxides, etc.

3.Chemical:

Aluminium polychlorid, disperse dyes, reactive dyes, organic catalyzer, white carbon black, washing powder, zinc sulfate, silica, sodium metasilicate, potassium fluoride, calcium carbonate, potassium sulfate, ingotganic catalyzer and all kinds of waste liquid, etc.

Q1: When can I get the price quotation ?

A1: We can send you the quotation within 24 hours after your inquiry , including the shipping cost if you need . Chat with us by Alibaba Trade Manager or directly send inquiry to our email .

Q2: What about payment term ?

A2: 100% by T/T; 40% as deposit, 60% balance before delivery.

Q3: How many about MOQ?

A3: MOQ is 1 unit.

Q4: What about the delivery?

A4: 45 working days after receiving deposit.

Q5: How about your delivery time?

A5: Generally, it will take 15 to 60 days after receiving your down payment. The specific delivery time depends on items and quantity of your order.

Q6: Do you test all your machine before delivery?

A6: We realize that the quality is the first priority for running our business and each equipment could be inspected before leaving factory.

If you are interested to learn more about information, pls feel free to contact us:

China

China