TRADE ASSURANCE Dear Customers: We have Trade Assurance granted by Alibaba.com, which means you will receive 100% refund for all of the orders if the products do not meet your quality requirement or delivery time! |

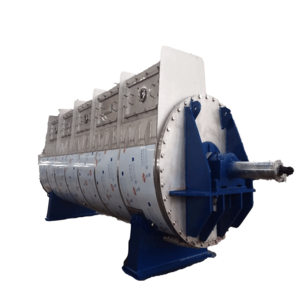

We have ASME certificates and Chinese pressure vessel design and manufacturing certificates from grade 1 to grade 3 We can design all types, all dimensions of reactors, pressure vessels, evaporators, dryers, distillation equipment, and the other chemical equipment as per customer's specific requirements. So please never hesitate to tell us what you want, and we are very glad to cooperate with you what we offer. |

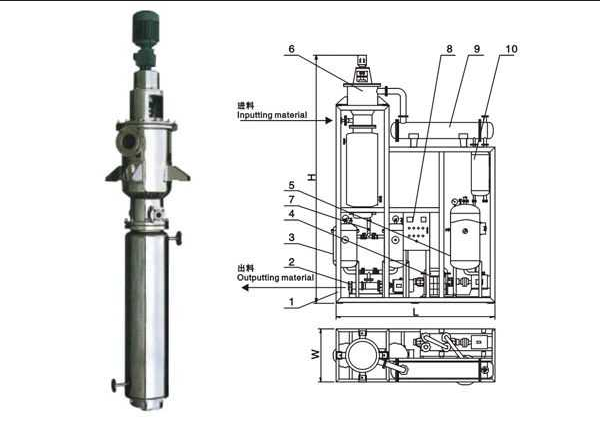

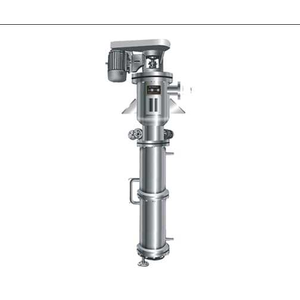

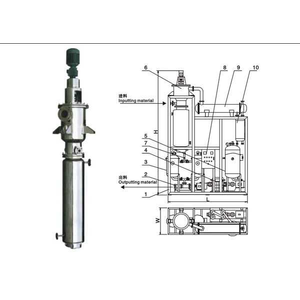

Summarization: Performances and Features Device takes up small room to have the features of simple structure, convenient maintenance and easy cleaning. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Main Technical Data: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1. We have 50 experienced workers holding certificate

2. We have 70 various processing machine.

3. Our chemical engineers, machinery engineers, electrical engineers, piping engineers... can specialized suggestions to you and are availabe for oversea service.

4. It take only 2 hours from our factory to Shanghai Port (Low local transportation cost).

5. We can either manufacture as per your specifications or design for you as per your requirements with ASME, CE or Chinese standard.

China

China