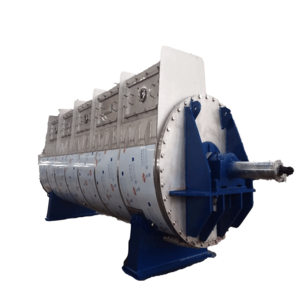

| Chemical pressure reactor |

| We have ASME certificates and Chinese pressure vessel design and manufacturing certificates from grade 1 to grade 3 |

We can design and manufacturing all types and all size of non standard chemical reactor according to your specific requirements. |

This polymerization reactor is the main part of the HIPS project we designed and produced for Iranian customer. |

|

Comparing other vendors, we have the following advantages:

1. We have 50 experienced workers holding certificate

2. We have 70 various processing machine.

3. Our chemical engineers, machinery engineers, electrical engineers, piping engineers... can specialized suggestions to you and are available for oversea service.

4. It take only 2 hours from our factory to Shanghai Port (Low local transportation cost).

5. We can either manufacture as per your specifications or design for you as per your requirements with ASME, CE or Chinese standard.

China

China