Specifications

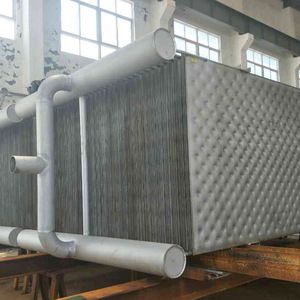

Plate type falling film evaporator

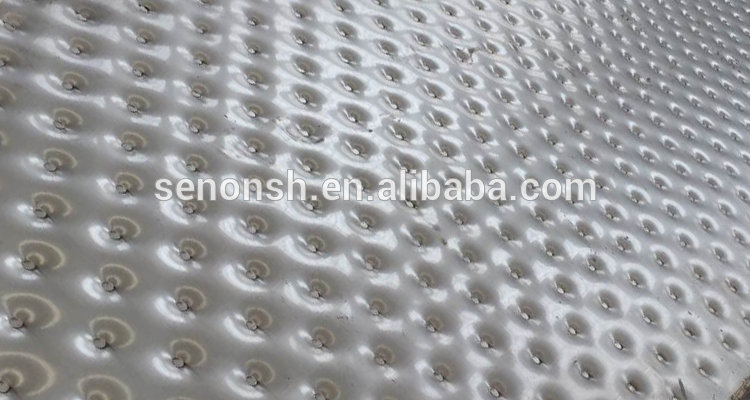

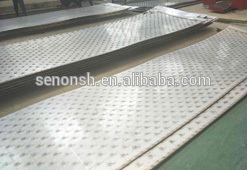

The working principle of the plate falling film evaporator is similar to that of tube falling film evaporators. But plates are used as heat elements, instead of the tubes. The plates, material can be chose as SS304, SS316L or duplex steel 2205, will be spot welded. After welding, the plates are pressed hydraulically into their final form. The positive characteristics of the plate falling film evaporator result from the design of the plates. A film flows down the heating plate surface. Because of the large distances between the plates and the cylindrical shell, the secondary vapor has plenty of space to spread out. Due to the low speeds, droplets are not to be expected.

Advantages of plate type falling film evaporator

1, The excellent cleaning properties:

1.1 The mechanical cleaning of the plates can be executed in large spaces.

1.2 Because of the large temperature differences between the operating and the cleaning temperature, the incrustations will peel off by their own.

2, Especially for vacuum applications, low pressure drop on the process side is another important advantage of the SENON plate falling film system.

Field of applications

1, black liquor treatment in paper-making industry

2, production/processes wastewater

3, solvent concentration in fiber industry

4, other industries for concentration

SENON is capable to design and supply many different types of equipment to achieve processing requirements. Our specialty is designing and installing innovative systems to convert liquid solutions into dry solids using evaporation and crystallization. Please reach us & let us know your requirements.

Looking forward to hear from you.

Shanghai SENON Co., Ltd. is one of global leaders in engineering, manufacturing, installing, debugging and training evaporation and crystallization equipment, used for fermentation industry, food industries, pulp and paper making industry, fiber industry, chemical industry, edible salt industry, lithium battery industry etc.

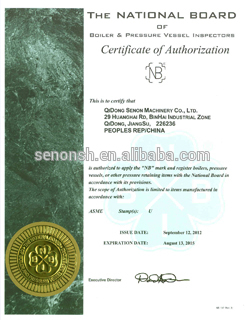

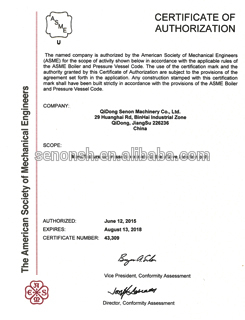

SENON has passed ISO9001:2008 quality management system certification, CE certification, ISO14001:2004 environmental management system certification, has gained A1, A2, ASME pressure vessel manufacturing qualification, A2 pressure vessel design qualification, mechanical and electrical equipment installation three-level qualification, as well as has the Independent import and export authority, more than twenty national patents. SENON is a high-tech enterprises in Shanghai. SENON brand is famous brand products of Shanghai.

China

China