Specifications

Multiple Effect Evaporator

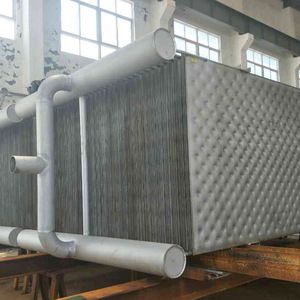

The multiple-effect configuration combines two or more evaporator bodies to conserve steam, which is condensed in the first-effect heat exchanger only. Water evaporated in the first-effect vapor body is condensed in the second-effect heat exchanger, which provides energy for evaporation in the second-effect vapor body (and so on for additional effects). Vapor from the last effect flows to a condenser.

The last-effect vapor body is maintained at a high vacuum with a steam-jet air ejector or mechanical vacuum pump. The driving force is the pressure drop from the first to the last effect.

The number of effects is limited by the total available temperature difference between the plant steam and the cooling water temperature. Process liquors with high boiling point elevations typically operate with fewer effects. SENON will help the clients to design most suitable effects to coordinate the first investment and the future operation fee.

Application

Industrial effluent concentration

Brine liquid concentration

Recovery of metal salts

Concentration of pharma and textile effluent

Pharma product concentration

Concentration of RO reject till saturation of salts in dissolve liquid

Secondary treatment

Dairy industry for milk evaporation

Fruit and tomato juice concentration

SENON is capable to design and supply many different types of equipment to achieve processing requirements. Our specialty is designing and installing innovative systems to convert liquid solutions into dry solids using evaporation and crystallization. Please reach us & let us know your requirements.

Looking forward to hear from you.

Shanghai SENON Co., Ltd. is one of global leaders in engineering, manufacturing, installing, debugging and training evaporation and crystallization equipment, used for fermentation industry, food industries, pulp and paper making industry, fiber industry, chemical industry, edible salt industry, lithium battery industry etc.

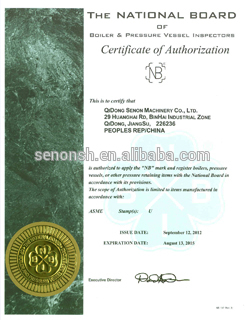

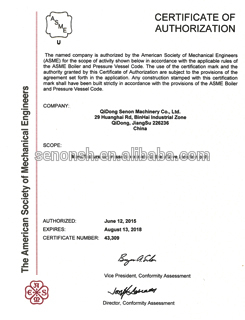

SENON has passed ISO9001:2008 quality management system certification, CE certification, ISO14001:2004 environmental management system certification, has gained A1, A2, ASME pressure vessel manufacturing qualification, A2 pressure vessel design qualification, mechanical and electrical equipment installation three-level qualification, as well as has the Independent import and export authority, more than twenty national patents. SENON is a high-tech enterprises in Shanghai. SENON brand is famous brand products of Shanghai.

China

China