Competitive price multiple effect film evaporator for food industry

1.Multi-effect evaporation

The heat released by 1kg steam condensation is basically the same as the heat absorbed by evaporation of 1kg water. Therefore to single-effect evaporation, 1kg water in the material for evaporation will consume 1 kg live steam; if the secondary steam is used to heat up the steam for the next effect, the consumption of secondary steam and live steam will be cut down by 50% When the number of effect increases, steam consumption decreases while the investment in equipment increases substantially. Therefore usually it shall not be more than 5 effects.

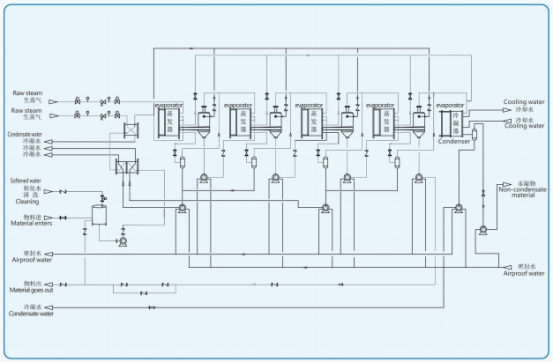

2.Schematic diagram

3.Application

Dairy products | Whole milk and skim milk powder, condensed milk, |

Protein | Soy bean milk, nutritional yeast and fodder yeast, |

Juice | Orange juice and other citrus juice, apple juice, |

Vegetable Juice | Beet root juice, tomato juice, and carrot juice |

Starch products | Glucose, dextrose, levulose, maltose, starch syrup, |

Suger | Liquid suger,refined white suger sweet water,and inulin |

Extract | Coffee and tea extract, hop extract, malt extract, |

Hydrolyzed material | Whey hydrolysates, seasonings, and protein hydrolysates |

Beer | Dealcoholized beer and malt wort |

ISO9001 quality management system certification and more than 20 patent certification was awarded.our goods verified by CNAS and IAF and some other third parties inspection

Jiangsu S-JE technology Co.,Ltd. is a newly established sub-company of Nanjing Gaojie Light industrial Equipment Co.Ltd. and has an export license. Jiangsu S-JE technology Co.,Ltd. specializes in supplying GSA-F series plate heat exchanger and imported plate; the largest domestic caliber plate condenser at home; semi-welded liquid ammonia evaporator; foreign imports of film and lifting film, falling film evaporator and plate evaporation system engineering services.Our company has experience in exporting heat exchange equipment and evaporating equipment to global. Our main markets are North America, Asia, Middle East and Africa.Now we are also developing new products to expand more market. We have our own designer and R&D group to develop new products and we can also creat new products in accordance with customers’requirements.Our company warmly welcomes all customers to visit our company. We hope to establish long-term and close cooperative relationships with our customers in order to achieve win-win benefits.

Jiangsu S-JE technology Co.,Ltd. is a newly established sub-company of Nanjing Gaojie Light industrial Equipment Co.Ltd. and has an export license. Jiangsu S-JE technology Co.,Ltd. specializes in supplying GSA-F series plate heat exchanger and imported plate; the largest domestic caliber plate condenser at home; semi-welded liquid ammonia evaporator; foreign imports of film and lifting film, falling film evaporator and plate evaporation system engineering services.Our company has experience in exporting heat exchange equipment and evaporating equipment to global. Our main markets are North America, Asia, Middle East and Africa.Now we are also developing new products to expand more market. We have our own designer and R&D group to develop new products and we can also creat new products in accordance with customers’requirements.Our company warmly welcomes all customers to visit our company. We hope to establish long-term and close cooperative relationships with our customers in order to achieve win-win benefits.

Our advantage

First: We have the most complete models plate heat exchanger at home and broad.

Second: We have heat exchanger sub-detachable, semi-welding, full welding, wide flow and irregular flow channel

Three: We have the entire system of integrated evaporation and design strength, the form of the evaporator at home and abroad ,the most full of film, falling film, lifting film series and a dozen different specifications of the model. Separate and semi-welded evaporator plates, equivalent to imported plates.

Four: We have the overall process design capabilities for the biological fermentation industry..

Five: We have heat exchanger and evaporator mold development strength.

Our Factory

China

China