Large capacity Automaic Modified starch Extruder Processing Machines introduction:

Oil Drilling Modified Starch making machine can produce Denatured Starch, Pre-gelatinized starch is an effective and economical fluid loss agent in water based drilling fluids, which is a starch derivative. It is not bacterial degradation when at 120°C, environmentally acceptable and non-toxic. Modified Starch can produce a thin, slick, tough filter cake and promotes faster penetration rates with reducer friction. It can be used in all kinds of drilling fluid system. Pre-gelatinized starch is also sometimes "pregelatinized" to make them easier to dissolve during product manufacture. Modified starch is widely used in oil drilling, textile, paper and food industries.

Main Features of Large capacity Automaic Modified starch Extruder Processing Machines

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

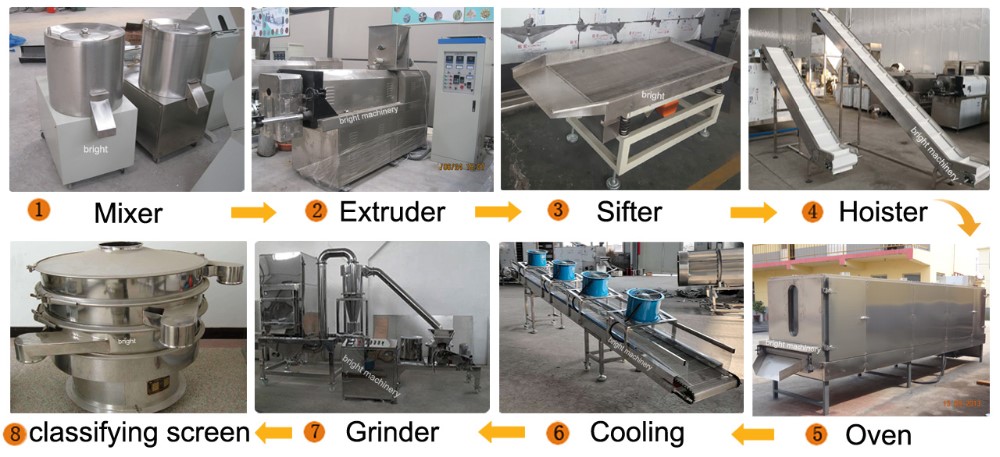

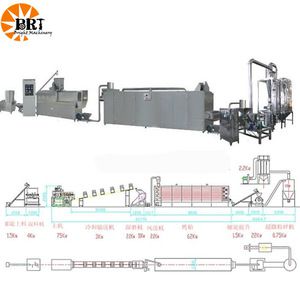

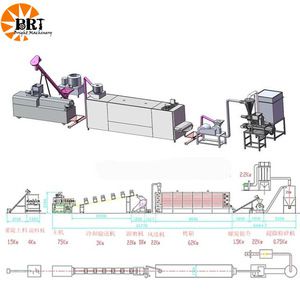

Flow chart :

Mixer— Screw conveyor—Twin-screw extruder— Sifter—Hoister— oven —Cooling machine — Grinder—Classifying screen

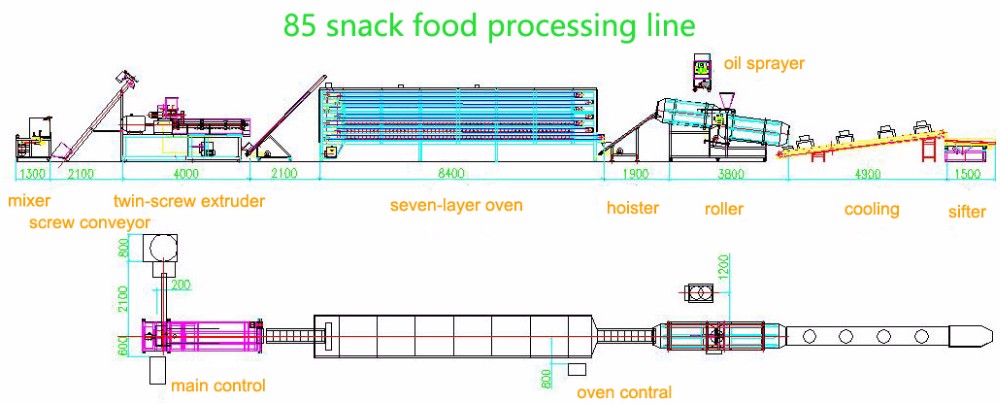

Flow chart diagram:

Our engineer could design the layout drawing according to your dimension of the factory for the fish feed machines

Technical parameter

| Model | InstalledPower (KW) | Power Consumption (kw) | Capacity (kg/h) | Dimension (m) |

| DSE65 processing line | 74 | 52 | 100-150 | 17*1.2*2.2 |

| DSE70 processing line | 95 | 70 | 200-300 | 20*1.5*2.2 |

| DSE85 processing line | 139 | 102 | 300-500 | 28*3.5*4.3 |

| DSE95 processing line | 200 | 160 | 800-1200 | 35*3.5*5.5 |

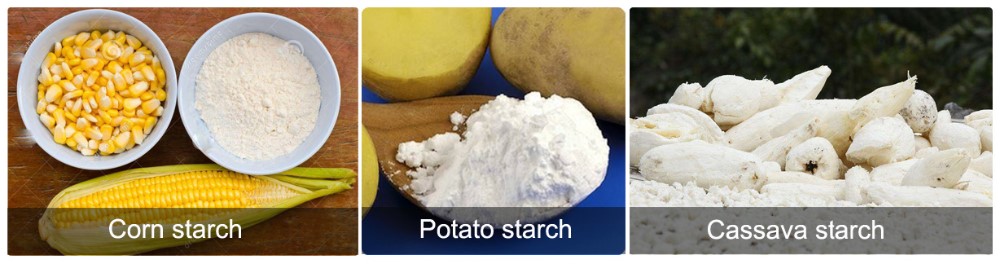

Raw material:

natural starch, like corn starch, cassava starch, tapioca starch etc

Sample of modified starch :

Equipment list in the snack food production line:

mixer→screw conveyor→twin screw extruder→air conveyor→dryer→hoister→Grinder→packing machine

1)mixer of Large capacity Automaic Modified starch Extruder Processing Machines

| Name | Mixer |

| Usage | To mix the raw materials evenly, fast speed, no leakage. |

| Type | including Single axle and double shaft mixer |

| Motor | 3kw, 4kw, 7.5kw etc. |

| Capacity | 20kg/time, 50kg/time, 100kg/time, 200kg/time, 500kg/time etc. |

| Material | stainless steel, carbon steel |

2)extruder of Large capacity Automaic Modified starch Extruder Processing Machines

| Name | Twin screw extruder(wet type/dry type) |

| Usage | To extrude the raw materials and make them to the required shape and size of the snack food pellets by mould |

| model | DSE65, 70, 75, 90, 95, 120, 135 |

| Motor | 22kw, 30kw, 55kw, 75kw, 90kw, 110kw etc. |

| Capacity | 100kg/h to 10 ton/h |

| Material | Screw materials 38CrMoAl stainless steel, carbon steel |

3)oven of Large capacity Automaic Modified starch Extruder Processing Machines

| Name | Dryer (oven) |

| Usage | the expanded food go through the “s” passage, to be dried to increase the self life. |

| Type | electrical, steam, gas fired, diesel fired heating type |

| Motor | KX-3-5, KX-5-5, KX-5-8, KX-5-10, KX-7-10 etc. |

| Capacity | 100kg/h to 10 ton/h |

| Material | stainless steel, carbon steel |

4)grinder of Large capacity Automaic Modified starch Extruder Processing Machines

| Name | Grinder |

| Usage | Through the high speed relative motion between the movable tooth disc and the fixed tooth disc, the comminuted material is crushed through the tooth impact, the friction and the impact of the material to each other and so on. |

| Motor | 22kw, 35kw, 55kw, |

| Capacity | 100kg/h to 10 ton/h |

| Material | stainless steel |

5)Sifter of Stainless steel drill modify starch making machine

| Name | Sifter |

| Usage | The crushing materials are classified and screened |

| Type | electrical |

| Motor | 5kw,7.5kw,15kw,22kw |

| Capacity | 100kg/h to 10 ton/h |

| Material | stainless steel |

6)packaging of Stainless steel drill modify starch making machine

| Name | Packaging machine |

| Usage | To pack the snack food with required weight |

| Flowing Process | Manual Bag placing→Automatic filling→Automatic weighing→ Automatic bag conveyor→Automatic bag sewing or heat sealing |

| Weight range | 1-5kg/bag, 5-25kg/bag, 25-50kg/bag |

| Material | stainless steel, carbon steel |

| Type | Automatic |

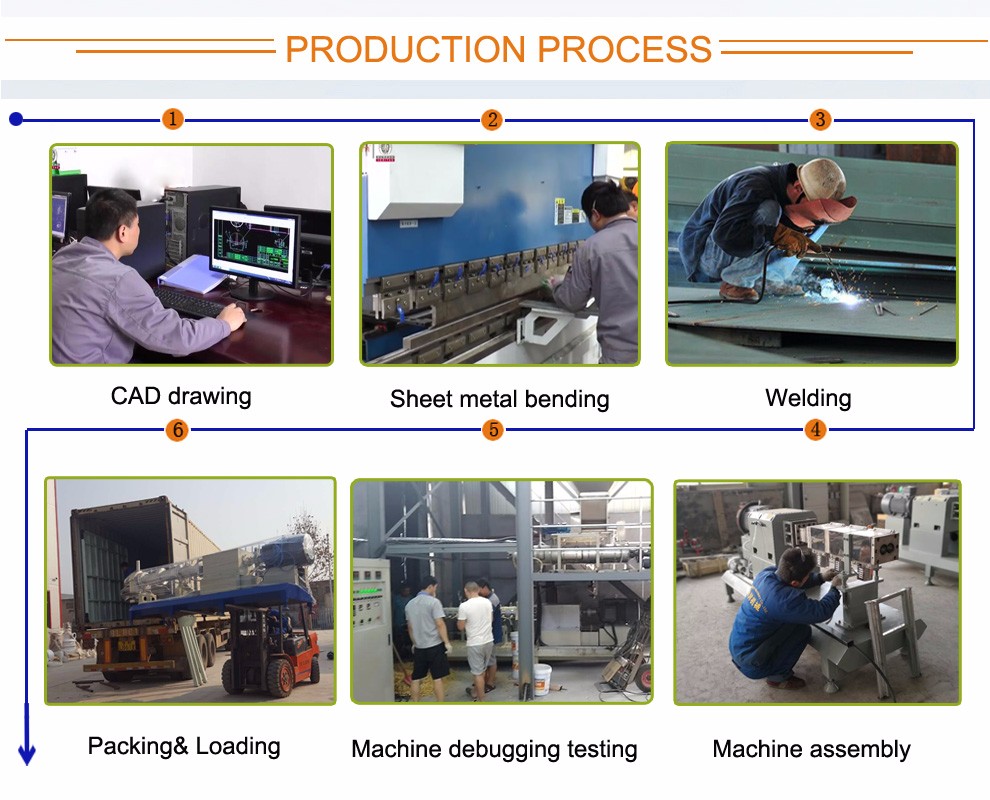

Bright company is in strict accordance with the industrial standards for cutting, bending, welding, strict

control of process quality, check whether the machine is qualified before delivery, to ensure that every machine for the customer is qualified artware selected carefully by Bright company.

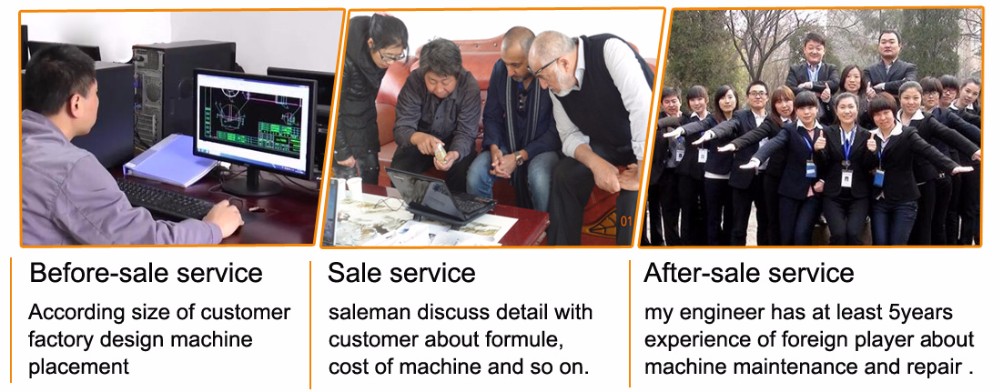

1.) Consultation service before, during,and after sales;

2.) Project planning and design service;

3.) Debugging of equipment until everything is functional;

4.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

5.) Training of equipment maintenance and operating personally;

6.) New production techniques and formulas;

7.) Provide 1 year complete warranty and life-time maintenance service.

Q: Are you a trade company or a manufacturer?

A: we are a manufacturer, welcome to visit and check the machine to my factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: 30% T/T in advance ,balance before shippment.

Q: How about the after-service?

A: We will send 1 engineer to the buyer’s factory for a 10-day period installation and training to the operators.

Q:do you supply any formula to buyer?

A:yes, we supply formula to buyer,

Why so many customers choose us :

1. Advantage technology

2. High quality material

3. Tight quality control

4. Accurate machine

5. 7 - 24 hours service

1.Use anti-rust oil to wipe the equipment for Large capacity Automaic Modified starch Extruder Processing Machines

2.air cushion film packaging equipment for Stainless steel drill modify starch making machine

3.with a wooden box for the final step of packaging.

China

China