Turn-key project cassava starch processing line on sale

Product description of cassava starch processing line

Cassava originated in the tropics area of South America, which is widely planted in all tropics areas over the world such as Nigeria, Innodesia, Cameroon, Brazil, Thailand etc.

Cassava contains some poison need to be processed though it is widely used for human being's food especially in Africa, animal feed and industries' development usage. So that is why directional machines are important and popular nowadays.

A full production line usually consists of different machines to form a combined line to finish the job of processing cassava into various of final products, so it is not a single part but a lot of parts together for industrial use.

Nutrition facts of cassava starch processing line

| Nutrition facts list(every 100g) | |

| Name | Content |

| Edible part | 99 |

| Moisture | 69 |

| Protein | 2.1 |

| Ash | 0.8 |

| Carbohydrate | 27.8 |

| Vitamin C | 35 |

| Fat | 0.3 |

| And some small content of metal elements |

From above form we could conclude fresh cassava tubers nutrition's facts as follows:

Starch 25% Vitamin C 4% Protein 1% Others 5% Moisture 65%

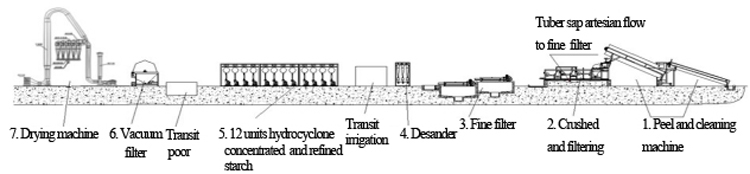

Flow chart of cassava starch processing line

Sections of cassava starch processing line

♦ Conveying/ lifting section

♦ Washing and peeling section

♦ Crushing section

♦ Filtering section

♦ Concentrating and extracting section

♦ Dewatering section

♦ Drying section

♦ Packing section

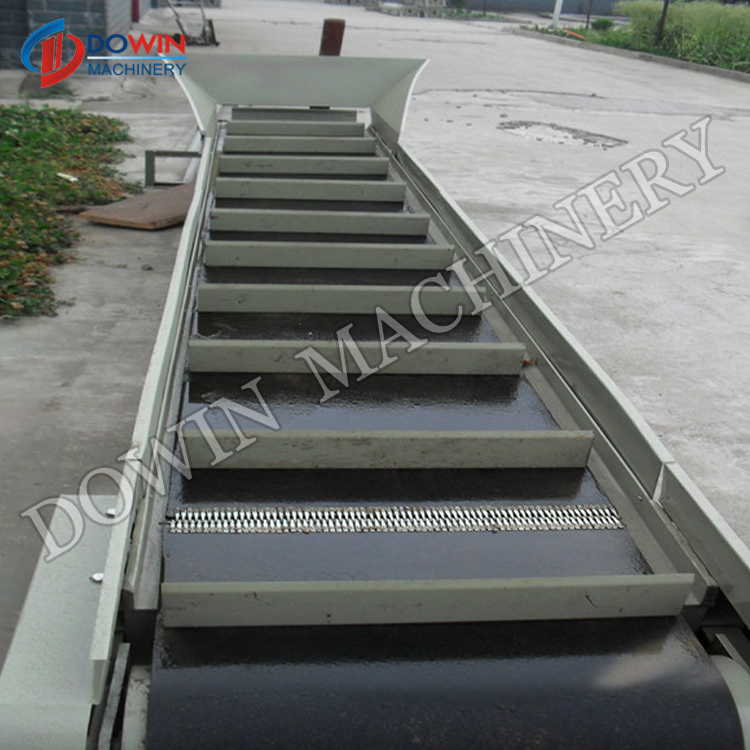

1. Conveying/ lifting section of cassava starch processing line

Lifting conveyor: Designed and manufactured according to the shape and size of cassava tubers and amount of raw materials entering could be adjustable and controlled.

2. Washing and peeling sections of cassava starch processing line

Paddle washing, cage washer, cage peeler and inspection table working together for each line to make sure the washing and peeling job is done very well to guarantee the final product's quality.

3.Crushing section of cassava starch processing line

Our patent mesh crusher consists of two stages of crushing, three stages of press filtering and flour stages of press washing with final crushing rate of 99%.

4. Filtering section of cassava starch processing line

This section have grit catcher, two fliters to fliter all impurities exiting in the starch slurry after crushing. They three work together with high efficiency and good results.

5.Concentrating and extracting section of cassava starch processing line

Hydrocyclone--This section is called crystallization and extraction section as starch is exiting by carbohydrate type, so crystallization step is quite important in process of extracting. Our hydrocyclone has reached top level of China with good result by 18 units to form a full set.

6. Dewatering section of cassava starch processing line

Dewatering machine--Once the drum rotating, outside and inside have a big pressure difference due to vacuum effect, then the liquid comes through filtering cloth to the vacuum pump till steam separator from which a fan driven out the vacuum to dry the materials inside the dewater drum. And it is recycling type. Moisture content from 65% to 45% through the machine.

7. Drying section of cassava starch processing line

Airflow dryer: Highest temperature 180 degrees, begining temperature could reach out to 130 degrees. Very fast drying. The out-feed temperature is about 50 degree. The moisture content could be 13% after drying to reach national standard grade A starch.

Boiler for dryer

Normal boiler have two different types: steam boiler and hot air boiler, it is used to generate hot air then convey into the dryer to dry the materials. Fuel could be wood, coal and gas.

8. Packing section of cassava starch processing line

Packaging and shipping of cassava starch processing line

1. Pre-sale service of cassava starch processing line

a) Our salers will give you the detailed introduction of the whole line.

b) Our engineers will design the factory layout for you.

c) We can design cassava production equipment according to your requests, such as the main material, the color and so on.

2. After-sale service of cassava starch processing line

a) We offer you the whole factory design and machines' installation drawing.

b) You can send your workers to our factory for learning before the shipping.

c) Machine operation training is free.

d) We will provide you the videos and pictures of the machines making process and package.

e) One year warranty for cassava production equipment

1. How can we see cassava starch processing line?

You are warmly welcome to visit our factory, and we have the working machine in factory, our engineers will

explain you the machines details one by one.

2. How many labors to operate cassava starch processing line?

The standard line just need about 5 labors to operate.

3. Will you help us to build the factory and install the machine?

Yes, it will take about 30 days for 2 people to install the whole production line. And our engineers will be sent

to your site to help you for the installation.

4. Will you offer training?

Yes, free training will be offered after the installation.

5. Where is your factory?

Our factory is located in Zhengzhou city which is the capital of Henan province, China. It is very convenient for

you to visit here, no mater you come here by train or by air.

| Contact sales | Michael Shan |

| 86-13027500519 | |

| Mobile phone | 86-13027500519 |

China

China