tapioca starch making machine

Introduction of DOWIN tapioca starch making machine

1 General on raw material

Cassava(Manihot esculenta Crantz), a species of sub- bush, is perennial plant which grows a circular roots that are greatly different from quantity and size because of different variety. Cassava root contains high starch content while it holds less protein, lipoids and ash. The fresh root of some good variety of cassava includes 25%~32% starchcontent on which cassava is shown as a good raw material for starch.

2 Principle of tapioca starch making machine

Cassava starch production is a physical process in which starch in cassava root is separated fromfiber, protein and inorganic and organic impurities. In production process, cassava starch is divorced from its suspension in water aiming at recovering it in accordance with the character of starch’s insolubility in water and heavier gravity than water by means of using water and specialized mechanical equipment.

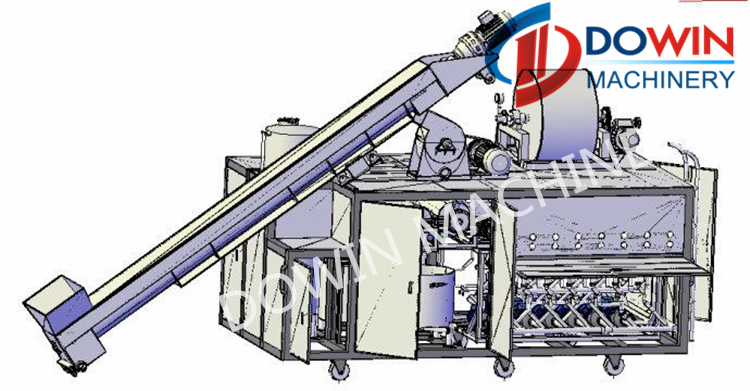

3 Design scheme of DOWIN mobile tapioca starch making machine

Dowin brand mobile cassava production line is really designed for the individual farmers and small scale cassava starch plant operator, it’s a new type cassava starch production equipment, with independent intellectual property rights, its unique processing technology is in a leading position in the world.

4 Advantages of DOWIN mobile tapioca starch making machine

a. High production ability;

b. Low water consumption;

c. Low power consumption;

d. High mobility;

e. Final products are with high quality;

f. The structure is reasonable and compact, containing a small cyclone group and small suction filter, the minimum amount of processing is only 100kg slurry, concentrate is high, the material slurry up to 24 Baume, after modification can be used as test equipment to meet the research institutes, factories experimental work.

5 Processing flow of DOWIN mobile tapioca starch making machine

Compared with the traditional small-scale equipment unit, the advanced nature of the mobile cassava production line is that using thesame technology processing as a large cassava starch production factory, built a set of dedicated mini-cyclone, crude starch slurry spin-liquid separation, the effective removal of fruit gum and protein, then get clean starch milk.

The whole process flow as follows:

a. Raw material;

b. Washing;

c. Crushing;

d. Dewater;

e. Refining;

g. Sand removing;

h. Separating residue;

i. Getting clean starch milk.

6 Main technical parameters of DOWIN mobile tapioca starch making machine

Equipment size ( L*W*H ) | 4508*2200*3035mm |

Equipment weight | 2760kg |

Equipment material | Polished stainless steel |

Main motor power | 48.5KW |

Raw material input capacity | 1000-1500 kg/hr |

Water consumption | 2000-2500 kg/hr |

Application | Potato, sweet potato, cassava ( if improved, it also can be used for mung bean and pea starch processing) |

7 Detail photos of DOWIN mobile tapioca starch making machine

a. In a small garage to process cassava

b. Inner structure of the mobile cassava starch production line

c. Separation effect is significant ( the left cup is Discharge liquid, the middle cup is Machine slurry, the right cup is refined starch milk )

d. Precipitated starch block (moisture content of about 42%)

e. After shipped to the factory, the workers are sending the starch block into the drying system

8 Certifications of DOWIN mobile tapioca starch making machine

Henan Dowin Machinery Company is the main manufacturer of cassava starch production line with more than 10 years experience in China. Our main machines cover cassava starch/flour processing machine, potato starch processing machine, garri processing machine and so on.

We have the professional technology, research, design and sale teams. And our main markets cover Africa (such as Nigeria, Ghana, Cameroon, Gabon and so on), Europe, America.....

1. Pre-sale Service of tapioca starch making machine :

a) Our salers will give you the detailed introduction of the whole line.

b) Our engineers will design the factory layout for you.

c) We can design the machine according to your requests, such as the main material, the color and so on.

2. After-sale Service of tapioca starch making machine :

a) We offer you the whole factory design and machines' installation drawing.

b) You can send your workers to our factory for learning before the shipping.

c) We offer machine operation training to you for free after the machine are installed.

d) We will provide you the videos and pictures of the machines making process and package.

e) One year warranty.

1. How can we see the working machines?

You are warmly welcome to visit our factory, and we have the working machine in factory, our engineers will explain you the machines details one by one.

2. How many labors to operate the production line?

The standard line just need about 5 labors to operate.

3. Will you help us to build the factory and install the machine?

Yes, it will take about 30 days for 2 people to install the whole production line. And our engineers will be sent to your site to help you for the installation.

4. Will you offer training?

Yes, free training will be offered after the installation.

5. Where is your factory?

Our factory is located in Zhengzhou city which is the capital of Henan province, China. It is very convenient for you to visit here, no mater you come here by train or by air.

China

China