Turn-key project 10t per day cassava flour extracting machine in nigeria

1, cassava flour processing machine

2, cassava flour making machine

3, cassava flour extraction machine

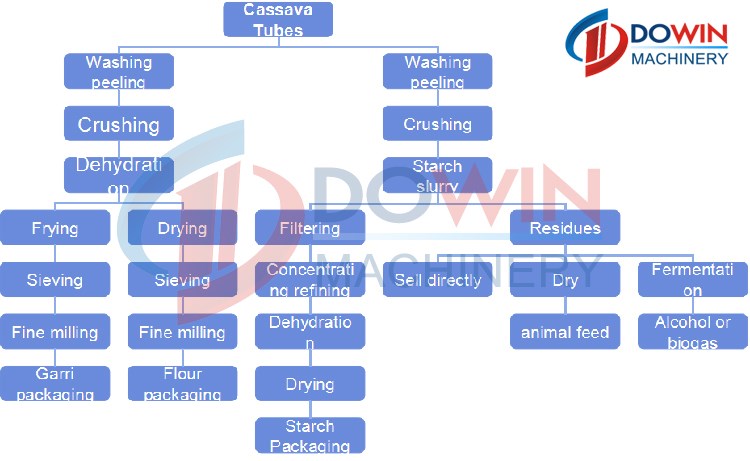

I. Production flow of 10t per day cassava flour extracting machine in nigeria

Peeling - Washing - Grating -Fermenting - Dewatering -Sifting -Drying -Remilling -Screening -Packing -Storage

II. Features of 10t per day cassava flour extracting machine in nigeria

a.Fully automatic line, connected well among all components.

b.Saving manpower, just need 5-6 persons to operate the complete line.

c.Saving 30% power and water.

d.Flour quantity from our machine is really high which can be made into some more delicious food like cake, bread and garri,etc.

It is mainly used for cassava, sweet potato, potato, yam and other roots to make the flour.

III. The whole processing line of 10t per day cassava flour extracting machine in nigeria

Article | Summary |

Scraper Lifter | Model No. GD-GB-400 Main Material: Carbon Steel Processing Ability: 2-5 Tons/Hour Profile: Adjustable Speed to conveying and lifting material to the next section. |

Washing Peeler | Model No. GD-QP-100 Main Material: Carbon Steel Processing Ability: 2-5 Tons/Hour Profile: Material rotated around the cage and goes along the post simultaneo usly, wash and peel without water. |

| Paddle type Washing Machine | Model No. GD-JY-350 Main Material: Carbon Steel Processing Ability: 2-5 Tons/Hour Profile: Cassava are conveyed into Blade-type Cleaning Machine, stirring, rubbing, tossing and striking in the U-groove (Figure) with water, and then the mud and epidermis get removed. |

Inclined Squirrel Cage Washing Machine | Model No. GD-SL-800 Main Material: Carbon Steel Processing Ability: 2-5 Tons/Hour Profile: Material enter into the rotary drum of New-type Squirrel-cage Cleaning Machine (Figure), while the drum is rotating material rolling forward, jet cleaning and rubbing, then the roots cleaning more cleaner and epidermis get further removed. Two sets of equipment get better cleaning effect. |

| Primary Crusher | Model No. GD-FS-100 Main Material: Stainless Steel Overall Processing Ability: 4-6Tons/Hour Profile: This grinder designs two stages of grinding: first is thorn nail rollermethod grinding, second is the hammer type. This design ensures the cassava get fully crushed and using less energy than the traditional way. This grinding isbetter to add less water or no water. Cassava flour processing requires higher fineness of the grinding. The material after grinding is no need for screening in order to avoid the loss of nutrients. In order to guarantee the flavor, color of cassava flour, the crushing material must take the oxidation process (fermentation).

|

Fermentation Tank | Several fermentation tanks should be built for leaving the crushed mash cassava materials fermented 3-7 days according to the temperature. Note: This fermentation process can keep the sour flavor of the flour. |

| Micro Crusher | Model No. GD-XM-100

Main Material: Carbon Steel or Stainless Steel

Processing Ability: 3-6 Tons/Hour

Profile: Fermented material pumped out into this fine mill by mash pump, then get fine milled into small and uniform particles (with water in the mash).

|

Tri-Legs Centrifuge | Model No. GD-SZ-100 Main Material: Stainless Steel Processing Ability: 3-8 Tons/Hour Profile: This dewatering machine ensures the continuity of the whole processing process. Note: centrifugal machine and plate-type filter presses also can be used for dewatering the mash materials, but not continuity. |

Airflow Drying System | Model No. GD-HG-300,500,1000,etc Main Material: Carbon Steel Output Ability: 0.3-1 Tons/Hour Profile: Wet material enter into the drying tube through powder feeder, then mixed with the fresh air which heated by radiator. Wet material suspended in hot air by the power of wind machine and can get dried by heat exchanging of heat and mass transfer process. (Natural drying method also can be used, or sell the wet starch directly.) |

Packaging Machine | Model No. GD-GB-400 Main Material: Carbon Steel Processing Ability: 0.005-0.5 Tons/Hour Profile: Adjustable weight scope, Automatically weighing and sealed by hand. |

IV. Key equipment introduction of 10t per day cassava flour extracting machine in nigeria

1> Washing & Peeling section

To remove the stone, sand or soil from the fresh cassava root, and peel it. (The peel of cassava is poisonous.)

2> Cassava Grinding machine section:

Grating is carried out by means of different kinds of graters. It disintegrates the cassava issue and frees up the moisture.

3> Fermenting:

Fermenting is very important for modern cassava processing industry, during fermenting to remove some kinds a material in the crushed cassava slag and satisfy with the human taste of the final cassava flour.

4> Cassava De-water machine ( Hydraulic Pressing ):

By using the principle of hydraulic and self-weight, nofilter chamber cavity, will directly press and squeeze the water under putting the material into the filter bag to further reduce the moisture content.

5> Sifting:

This necessary step after pressing of the flour ,use the sifting machine to sieve for next step airflow flash drying.

6> Drying and Packing section:

The flash dryer designed and manufactured by DOWIN is not only suitable for all kinds of tubers starch drying, but also corn and wheat starch drying, to completely remove the water in the pressed cassava slurry for final milling and packing.

V. Customer's plant of 10t per day cassava flour extracting machine in nigeria

VI. Customers' visiting of 10t per day cassava flour extracting machine in nigeria

VII. Certification of 10t per day cassava flour extracting machine in nigeria

VIII. Packing details of 10t per day cassava flour extracting machine in nigeria

wooden box, naked package or international standard package.

Henan Dowin Machinery Company is the main manufacturer of cassava starch production line with more than 10 years experience in China. Our main machinescover cassava starch/flour processing machine, potato starch processing machine, garri processing machine and so on.

We have the professional technology, research, design and sale teams. And our main markets cover Africa (such as Nigeria, Ghana, Cameroon, Gabon and so on), Europe, America.....

VIIII. Our advantages of 10t per day cassava flour extracting machine in nigeria

1.. Advanced and reliable cassava starch, flour processing technology.

2. Energy-saving, water-saving, labor-saving and little pollution. hot recycling close type production and the process water will be recycled.

3. Mostly machinery with fully stainless steel to be sure these is no corrosion.

4. Advanced surface treatment craft. Oil and dirty resisting.

5. Many various capacity option , customized cassava starch production line available.

The best solution project and highest possible quality machines will be offered

according to your Demands. Maximum your cost performance.

1. Pre-sale Service:

a) Our salers will give a detailed introduction and explanation to the whole line.

b) Our engineer will design the factory layout for you.

c) We can offer you the OEM, basis on your request.

2. After-sales Service:

a) We can offer the Turkey Project for your request.

b) We offer you the whole factory design and machines' installation drawing.

c) You can sell our worker to our factory for learning before the goods shipping.

d) We will offer machine operation trainning and guide for free when machine being installed.

e) One year warranty and lifetime maintaining .

Qoute offer procedure of 10t per day cassava flour extracting machine in nigeria

1>Before exact quote, it better inform us at least the following informations:

1. How many capacity of project you want?

The capacity of project means how many product do you want to get in one hour or

how many raw material do you want to deal with in one hour?

2. What kind of material do you want to deal?

2>More information better for cooperation

3. important character for us.

a) Starch content

b) Fiber content

4.The main fuel for heat system in local

5.For heat resource of the drying system, we can provide followin choice, what is your

choice? Or which is normal in local?

Hot oil boiler

Steam boiler

Hot air generator

6.The supply type do you want to use in the project:

a) Turnkey of all system

b) Part section turnkey

c) Part section system

d) Single machine

7.the schedule of project

8.Location of project

Contact information

1. Contact person: Wendy Yue

2. Skype: jtdny01

3. WhatsApp: 0086 13164317138

Detailed information about the 10t per day cassava flour extracting machine in nigeria, welcome to contact us, we are always at your service.

China

China