Ion Exchange Water Softening System

Introduction

Ion exchange units that replace calcium and magnesium ions from water are known as water softeners. They may also remove varying amounts of other inorganic pollutants such as metals, but they will not remove organic chemicals, pathogens, particles, or radon gas. Water softener units work most efficiently with particulate-free water.

Principles of Ion Exchange to Soften Water

Calcium and magnesium ions are atoms having a positive electrical charge, as do sodium and potassium ions. Ions of the same charge can be exchanged. In the ion exchange process, a granular substance (usually a resin) that is coated with sodium or potassium ions comes into contact with water containing calcium and magnesium ions. Two positively charged sodium or potassium ions are exchanged (released into the water) for every calcium or magnesium ion that is held by the resin. This "exchange or trade" happens because sodium or potassium are loosely held by the resin. In this way, calcium and magnesium ions responsible for hardness are removed from the water, held by the resin, and replaced by sodium or potassium ions in the water. This process makes water "soft." Eventually, a point is reached when very few sodium or potassium ions remain on the resin, thus no more calcium or magnesium ions can be removed from the incoming water. The resin at this point is said to be "exhausted" or "spent," and must be "recharged" or "regenerated."

Ion Exchange Unit Components

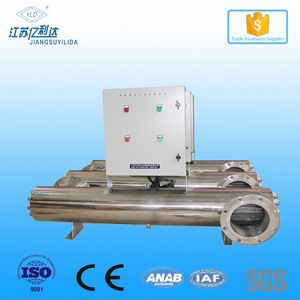

A water softener can be as simple as a tank to hold the exchange resin, together with appropriate piping for raw (inlet) and treated (outlet) water. Modern water softeners include a separate tank for the brine solutions used to regenerate the resin, additional valves to back-wash the resin, and switches for automatic operation.

Plumbing Requirements

New homes are plumbed for water softeners. Plumbing old homes for soft water can be very expensive. Not all the water coming into a home needs treatment. If the water is classified as very hard (10.5 or more grains per gallon or 180 or more mg/L of calcium carbonate), a house point-of-entry (POE) treatment may be needed. Otherwise, only the hot water supply should be treated to reduce formation of calcium deposits (scale) in the water heater and pipes.

Personal preference may also influence the decision to treat hot and cold supplies going to the laundry room, showers, and sinks. Toilets and outdoor faucets should not receive softened water. Softened and untreated water may also be "blended" to produce water with a lower hardness and to decrease the amount of water that must be treated.

Unit Selection

The selection of a water softening unit depends on the hardness of the raw water and the amount of water to be softened. There are manual, automatic, semiautomatic, and fully automatic units that differ in the degree of resin regeneration automation. First, the number of fixtures in the home that will require softened water must be determined. Then, all the fixtures' flow rates need to be added up. Note that conventional faucets use 3-5 gallons per minute (gpm) and conventional showers use 5-10 gpm. (Newer, water-saving fixtures may use only half these amounts.)

Working configuration:singe-valve and dual-tank,one tank is working,the other tank is standby,alternative regeneration for continuous 24 hours working.

01. By means of Absorbing the calcium and magnesium ions in water with resin, since the hardness of water is mainly composed of calcium and magnesium, in general, we adopt cation exchange resin (softener), replace Ca2+, Mg2+ (main ingredients for scale) in water, as the increase of Ca2+ and Mg2+ in resin, removing performance on Ca2+, Mg2+ of resin will gradually reduce.

02. When the resin has absorbed a certain amount of calcium and magnesium ions, it must be regenerated, the regeneration process is that flush resin layer with the salt water in salt box, replace hardness ion out of the resin again, and discharged from the tank with waste liquid of regeneration, then resin resumed the function of softening and exchanging.

03. The principle of sodium ion exchange and softening treatment is to exchange cation in the raw water with resin, hardness constituents Ca2+and Mg2+ in water exchange Na+ in resin, thus absorb the Ca2+and Mg2+ to make the water to be softened.

2RNa + Ca2+ = R2Ca + 2Na+

2RNa + Mg2+ = R2Mg + 2Na+

After the water treated by sodium ion exchanger, the Ca+ and Mg+ were superseded by Na +.

Application scope of softener

Mainly used in industry and civil water softening preparation, such as Boiler feed water make-up water, air conditioning system make up water, heat exchanger, power plant, chemical, textile, printing and dyeing, bio-pharmaceutical, Electronic system and water pretreatment.

Type choice:

Softener equipment applies cation resin for softing raw water,its main target is to use cation resin to adsorp (main parts of ),encreasing the hardness of raw water.

1. Users can choose manual operation control system for saving cost.

2. If users using for 24 hours can accord to water using time choosing for rebirth

3. Uses can according to water quality requirement:first grade multi-media filter,which can remove mud,rust,colloid and suspension in water.Second grade activated carbon filter,which can remove color,olfactory,biochemistry organic in water and encrease the left oxygen value and pollution in water.Third grade equiped softener equipment.

4. Effluent water capacity achieves the water supply of national low-pressure bioler.

5. Time control- type;flow control- type.In working ,apply single-tank,double-tank and multi-tank etc. other varied combination method.When choosing,users can choose as their needs.In operation,it has not only automatic function,but also is manual operation.

Technoloty index and working

Water pressure:0.18-0.6Mpa

Working temperature:1°c-55°c

Hardness of raw water: <8mmol/L

Operation method:manual/automatic

Hardness of effluent water: ≤0.03mmol/L

water flow: 0.3-100 m3/hour

Rebirth method:

Control method: time or flow

Working electric: 220V/50Hz

Water softener for hardness removing

Model I : dual-tank and dual-valve, two tanks running simultaneously and regenerate respectively.

| Model | water output (m³/hour) | Resin-tank (diameter*Height) | Brine-tank(Liter) | Resin (kg) | connecting pipe(inch) |

| YL-II-0.5A | 0.5 | 200×1200 | 60 | 40 | 3/4 |

| YL-II-1A | 1 | 250×1400 | 60 | 80 | 3/4 |

| YL-II-2A | 2 | 300×1400 | 100 | 120 | 1 |

| YL-II-3A | 3 | 350×1650 | 200 | 160 | 1 |

| YL-II-4A | 4 | 400×1800 | 200 | 240 | 1 |

| YL-II-5A | 5 | 500×1800 | 200 | 360 | 1 |

| YL-II-6A | 6 | 600×1850 | 350 | 480 | 1.5 |

| YL-II-10A | 10 | 750×1850 | 500 | 720 | 1.5 |

| YL-II-18A | 14-18 | 900×1850 | 500 | 720 | 1.5 |

| YL-II-25A | 20--25 | 750*1850 | 500 | 720 | 2 |

| YL-II-36A | 30--36 | 900*1900 | 800 | 1040 | 3 |

| YL-II-50A | 45--50 | 1200*2400 | 1000 | 1440 | 3 |

| YL-II-70A | 60--70 | 1200*2400 | 1500 | 2000 | 3 |

| YL-II-100A | 80--100 | 1500*2500 | 2000 | 3200 | 3 |

the other one is stand-by.

| Model | water output | Resin-tank | Brine tank (Liter) | Resin (kg) | connecting pipe(inch) |

| m³/hour | (diameter*Height) | ||||

| YL-II-1B | 1 | 250×1400 | 60 | 80 | 3/4 |

| YL-II-2B | 2 | 300×1400 | 100 | 120 | 1 |

| YL-II-3B | 3 | 350×1400 | 100 | 160 | 1 |

| YL-II-4B | 4 | 400×1650 | 200 | 240 | 1 |

| YL-II-5B | 5 | 500×1750 | 300 | 360 | 1 |

| YL-II-6B | 6 | 600×1850 | 350 | 480 | 1.5 |

| YL-II-10B | 8--10 | 750×1900 | 500 | 720 | 1.5 |

| YL-II-18B | 12--18 | 900*2400 | 800 | 1040 | 2 |

| YL-II-25B | 20--25 | 1000*2200 | 1000 | 1440 | 2 |

| YL-II-35B | 30--35 | 1200*2400 | 1500 | 2000 | 3 |

| YL-II-50B | 40--50 | 1500*2400 | 2000 | 3200 | 3 |

Model III. Single-tank and single-valve(time setting based or flow rate based)

| Model | water output (m³/hour) | Resin-Tank (diameter*Height) | Brine tank (Liter) | Resin (kg) | connecting pipe(inch) |

| YL-I-0.5 | 0.5 | 200×1200 | 60 | 20 | 3/4 |

| YL-I-1 | 1 | 250×1400 | 60 | 40 | 3/4 |

| YL-I-2 | 2 | 300×1400 | 100 | 60 | 1 |

| YL-I-3 | 3 | 350×1650 | 200 | 80 | 1 |

| YL-I-4 | 4 | 400×1650 | 200 | 120 | 1 |

| YL-I-5 | 5 | 500×1800 | 200 | 180 | 1 |

| YL-I-6 | 6 | 600×1850 | 350 | 240 | 1.5 |

| YL-I-10 | 10 | 750×1850 | 500 | 360 | 1.5 |

| YL-I-16 | 16 | 900*2200 | 1000 | 520 | 2 |

| YL-I-20 | 20 | 1000*2200 | 1500 | 720 | 2 |

| YL-I-28 | 28 | 1200*2400 | 2000 | 1000 | 3 |

| YL-I-50 | 50 | 1500*2400 | 2000 | 1600 | 3 |

China

China